Device and method for testing hydrogen sulfide stress corrosion resistance of oil well pipe

A hydrogen sulfide-resistant and stress-corrosion-resistant technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, using stable tension/pressure to test the strength of materials, etc., can solve complex model design and theoretical calculations, complex theoretical calculations, Issues such as failure and non-failure to achieve the effect of reducing human measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the samples used in the test are oil well pipes A and B, and three parallel samples are made for each material. The test process is as follows:

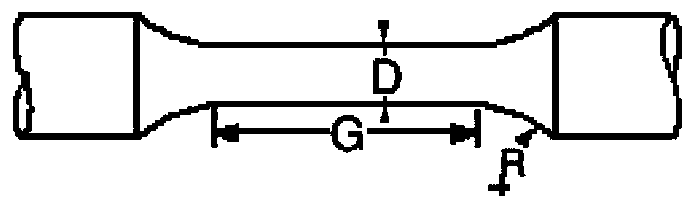

[0043] A) if figure 2 As shown, the processing size of sample 3 is the diameter of the test area D=φ6.35±0.13mm, the length G=25.4±0.2mm, and the transition fillet between the test area of the sample and the clamping section at both ends is R; after processing The surface finish of sample 3 is 0.2 μm; the surface of sample 3 after processing is scrubbed twice with acetone, and then scrubbed with absolute ethanol once to remove the residue and grease on the surface of sample 3;

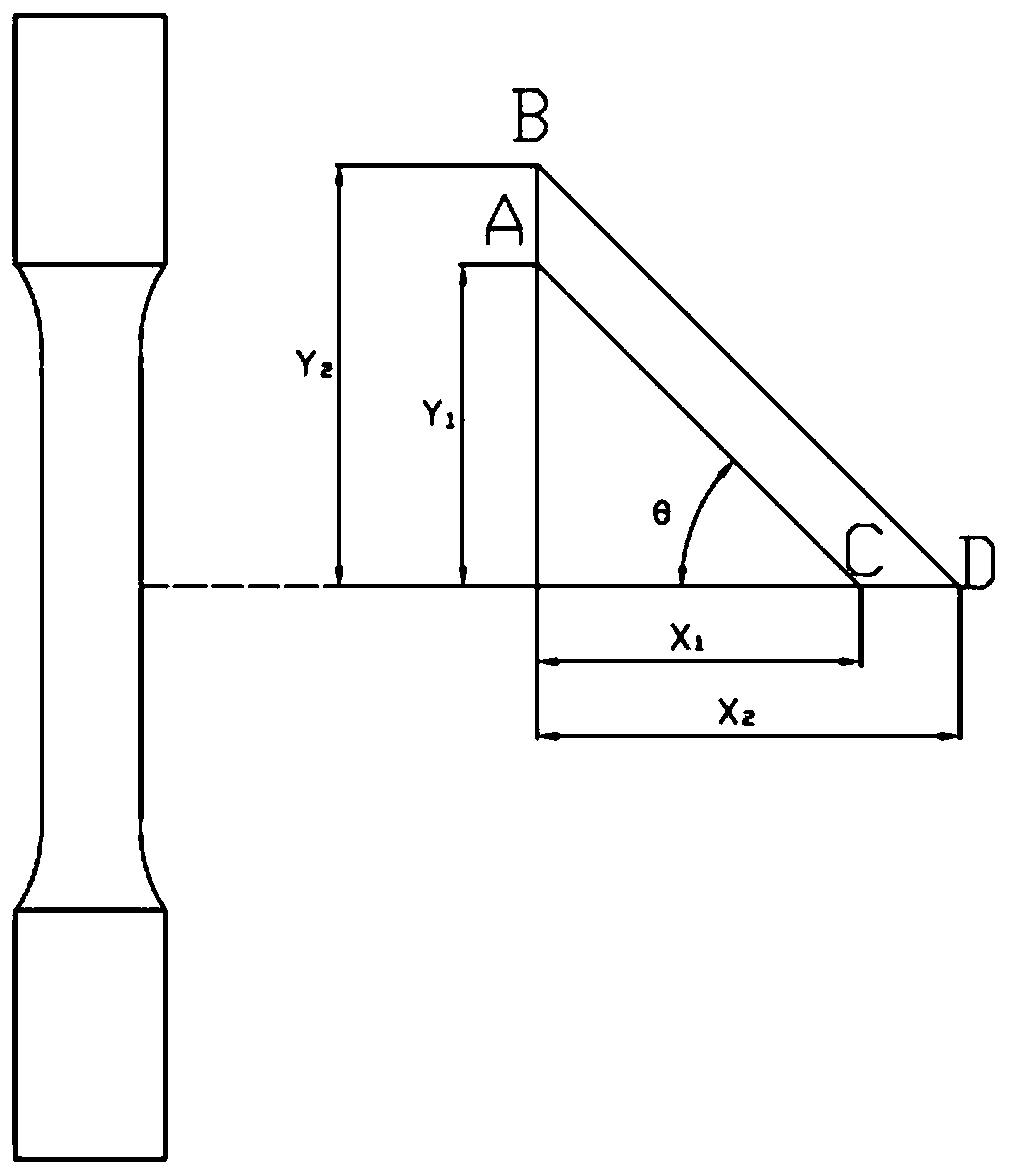

[0044] B) mark the sample test area, mainly marking the middle point and the upper and lower boundary points of the sample test area, so as to facilitate the identification of the laser detector 6;

[0045] C) Fix the laser detector 6 and the laser detector moving device 9 on the slideway, keep the slideway level, adjust the pos...

Embodiment 2

[0055] In this embodiment, the samples used in the test are oil well pipes A and B, and three parallel samples are made for each material. The test process is as follows.

[0056] A) if figure 2 As shown, the processing size of sample 3 is: the diameter of the test area of the sample D=φ6.35±0.13mm, the length G=25.4±0.2mm, the surface finish of sample 3 after processing is 0.2μm; the processed sample 3 Scrub the surface twice with acetone, and then scrub it once with absolute ethanol to remove the residue and grease on the surface of sample 3;

[0057] B) mark the sample test area, mainly marking the middle point and the upper and lower boundary points of the sample test area, so as to facilitate the identification of the laser detector 6;

[0058] C) fixing the laser detector 6 and the laser detector moving device on the slideway, keeping the slideway horizontal, so that the laser beam emitted by the laser detector 6 is vertically irradiated onto the measured surface of ...

Embodiment 3

[0068] In this embodiment, the samples used in the test are oil well pipes A and B, and three parallel samples are made for each material. The test process is as follows:

[0069] A) if figure 2 As shown, the processing size of sample 3 is: the diameter of the sample test area D=φ6.35±0.13mm, the length G=25.4±0.2mm, the surface finish of sample 3 after processing is 0.2μm; the processed sample 3 Scrub the surface twice with acetone and once with absolute ethanol to remove the residue and grease on the surface of sample 3;

[0070] B) mark the sample test area, mainly marking the middle point and the upper and lower boundary points of the sample test area, so as to facilitate the identification of the laser detector 6;

[0071] C) fixing the laser detector 6 and the laser detector moving device on the slideway, keeping the slideway horizontal, so that the laser beam emitted by the laser detector 6 is irradiated vertically to the measured surface of the sample 3;

[0072] D)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com