Amorphous carbon modified SiC nanowire continuous three-dimensional network structure wave-absorbing foam and preparation method thereof

A network structure and nanowire technology, applied in the field of wave-absorbing materials, can solve problems such as difficulty in forming a continuous structure, light weight and broadband need to be further improved, absorption performance lower than expected, etc., to protect integrity and enhance electromagnetic absorption performance and mechanical properties, to ensure the effect of structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

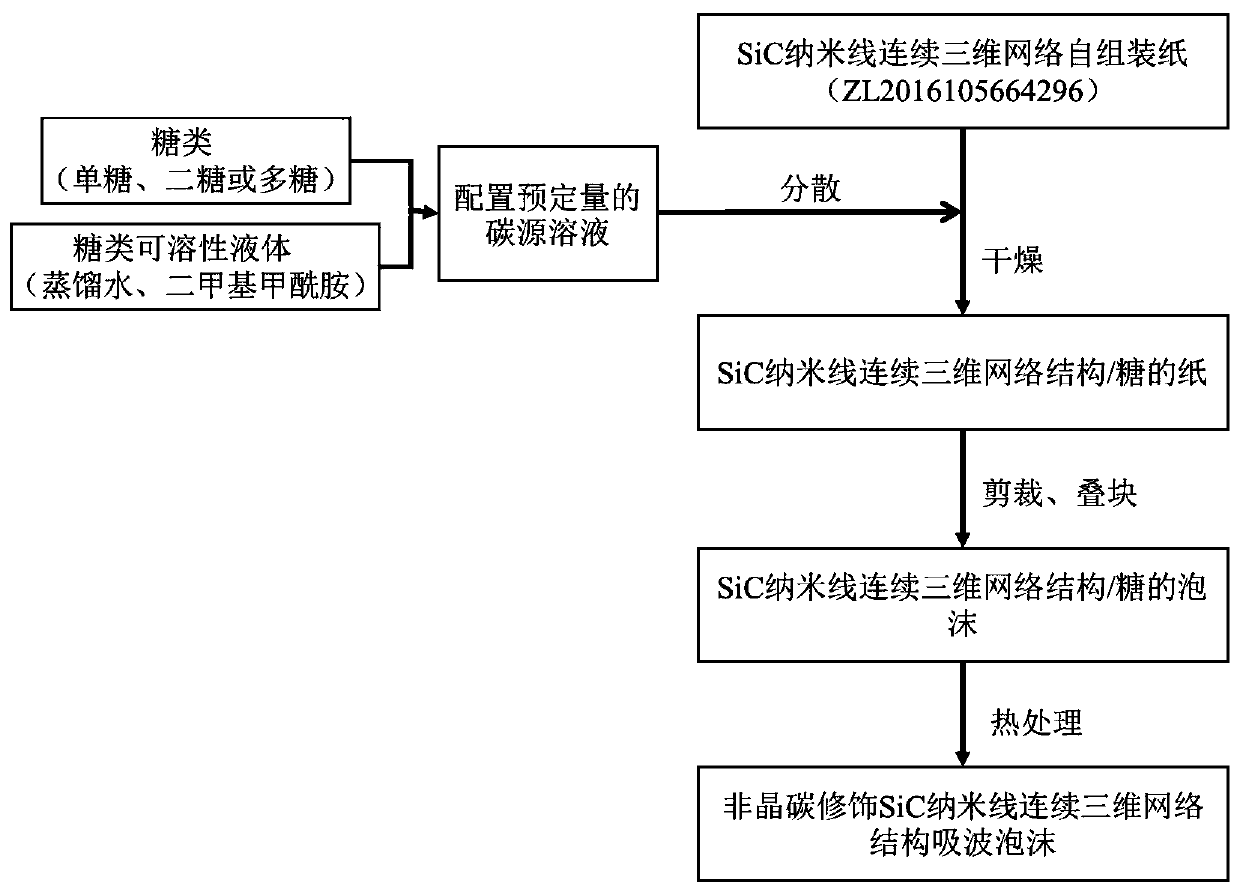

[0036] The preparation method proposed by the first embodiment of the present invention, such as figure 1 Shown, described method preparation process is as follows:

[0037] Glucose was selected as the carbon source, distilled water was used as the solvent, and the two were uniformly mixed in a certain proportion to form a carbon source solution with a concentration of 1 wt%. The carbon source solution was dispersed into the continuous three-dimensional network structure of SiC nanowires by spraying to make the carbon source evenly Coat the surface of SiC nanowires and build more nodes to obtain a thin film constructed of SiC@carbon source, and dry it at a temperature of 40°C and a drying time of 2 hours; design the shape of the dried product and cut it out for stamping , followed by superimposing the film into a block for hot-pressing treatment, carbonization treatment in an oxygen-free inert atmosphere, the heat treatment temperature is 500 ° C, and the holding time is 5 hou...

Embodiment 2

[0041] Glucose was selected as the carbon source, distilled water was used as the solvent, and the two were uniformly mixed in a certain proportion to form a carbon source solution with a concentration of 1 wt%. The carbon source solution was dispersed into the continuous three-dimensional network structure of SiC nanowires by spraying to make the carbon source evenly Cover the surface of SiC nanowires and build more nodes to obtain a film constructed of SiC@carbon source, and dry it at a temperature of 70 ° C and a drying time of 1 h; shape the dried product and cut it out for stamping , followed by superimposing the film into a block for hot-pressing treatment, carbonization treatment in an oxygen-free inert atmosphere, the heat treatment temperature is 1000 ° C, and the holding time is 1 h, and the amorphous carbon-modified SiC nanowire continuous three-dimensional network structure absorbing foam is obtained.

Embodiment 3

[0043] Glucose was selected as the carbon source, distilled water was used as the solvent, and the two were evenly mixed in a certain proportion to form a carbon source solution with a concentration of 0.5 wt%. The carbon source solution was dispersed into the continuous three-dimensional network structure of SiC nanowires by spraying, so that the carbon source Uniformly coat the surface of SiC nanowires and build more nodes to obtain a film constructed of SiC@carbon source, and dry it at a temperature of 140°C and a drying time of 1 hour; shape the dried product and cut it Stamping, followed by superimposing the film into a block for hot-pressing treatment, carbonization treatment in an oxygen-free inert atmosphere, the heat treatment temperature is 1300 ° C, and the holding time is 1 h, and the amorphous carbon-modified SiC nanowire continuous three-dimensional network structure absorbing foam is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com