Method for preparing ITO (Indium Tin Oxide) granulation powder by mixing method

A technology of granulating powder and mixing method, which is applied in the field of preparation of ITO granulating powder, can solve the problems of dispersant failure, complicated operation, difficult to transfer clean, etc., and achieve the goal of reducing grinding time, avoiding particle agglomeration, and shortening grinding time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

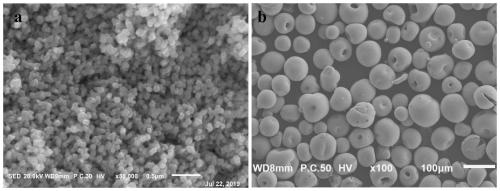

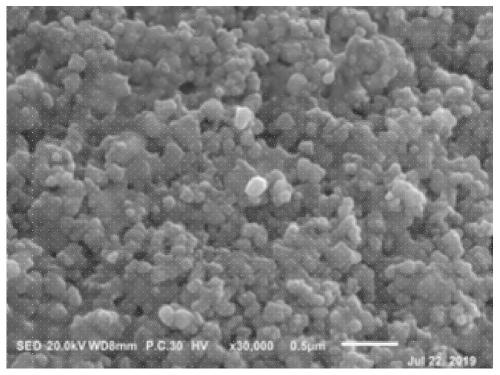

Image

Examples

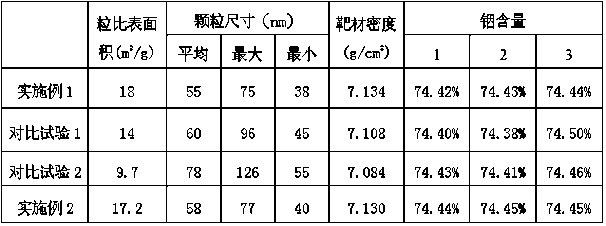

Embodiment 1

[0033] Embodiment 1: Get 90Kg of indium oxide powder and 10Kg of tin oxide powder, the average grain size of indium oxide powder is 120nm, the average grain size of tin oxide powder is 70nm, standby; Get 0.5Kg of polycarboxylic acid compound Dispersant and 1.5Kg of polyvinyl alcohol are dissolved in deionized water to form a mixed solution of 40Kg, the weighed powder is added to the mixed solution, and a pre-dispersed slurry with a solid content of 71.4% is prepared under stirring; Put the slurry into an ultrasonic instrument with an ultrasonic frequency of 40 Hz for 30 minutes, then add it to a sand mill and grind it for 1 hour. When the corresponding slurry particle size D50 is 0.5 micron and D90 is 1 micron, add a few drops of n-butanol to Defoaming to prepare a mixed slurry, spray drying to obtain ITO granulated powder, wherein the inlet air temperature is 220°C, the outlet air temperature is 100°C, and the atomizer frequency is 30Hz.

[0034] Comparative test 1 (the steps...

Embodiment 2

[0038] Embodiment 2: Get 90Kg of indium oxide powder and 10Kg of tin oxide powder, the average grain size of indium oxide powder is 100nm, the average grain size of tin oxide powder is 100nm, standby; Get 0.7Kg of polyvinylpyrrolidone dispersant Dissolve carboxymethyl cellulose and 1.5Kg in deionized water to form a mixed solution of 40Kg, add the weighed powder into this mixed solution, and make a pre-dispersed slurry with a solid content of 71.4% under stirring; Put the slurry into an ultrasonic instrument with an ultrasonic frequency of 40 Hz for 30 minutes, then add it to a sand mill and grind it for 1 hour. When the corresponding slurry particle size D50 is 0.4 micron and D90 is 0.9 micron, add a few drops of n-butanol to Defoaming to prepare a mixed slurry, spray drying to obtain ITO granulated powder, wherein the inlet air temperature is 180°C, the outlet air temperature is 80°C, and the atomizer frequency is 35Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com