Method for preparing thermal expansion microspheres based on interfacial polymerization

A technology of thermally expanding microspheres and interfacial polymerization, which is applied in the field of preparation of thermally expanding microspheres, can solve the problems of solvent resistance, low residual monomer content and high residual monomer content of large thermally expanding microspheres, and achieves low monomer residual, low monomer residual The effect of high conversion rate and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

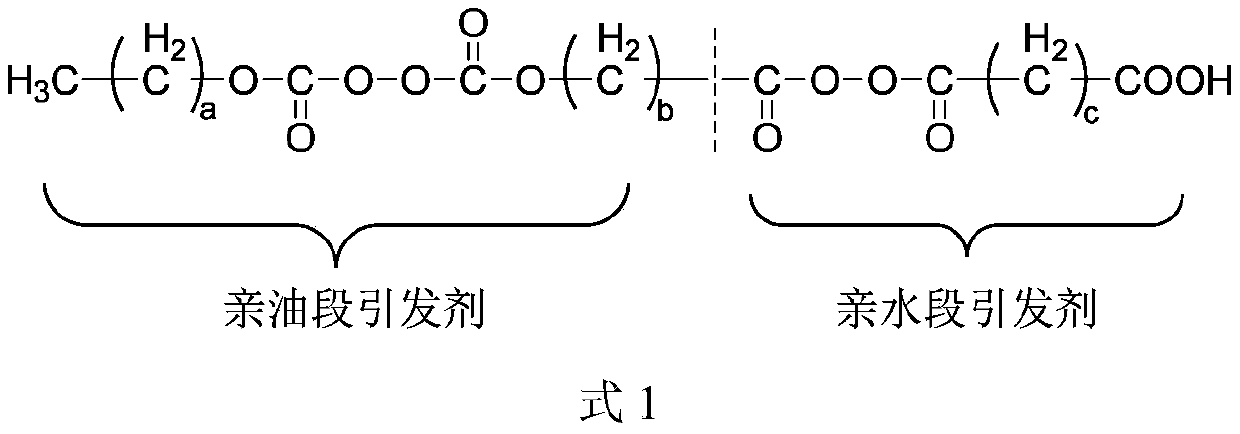

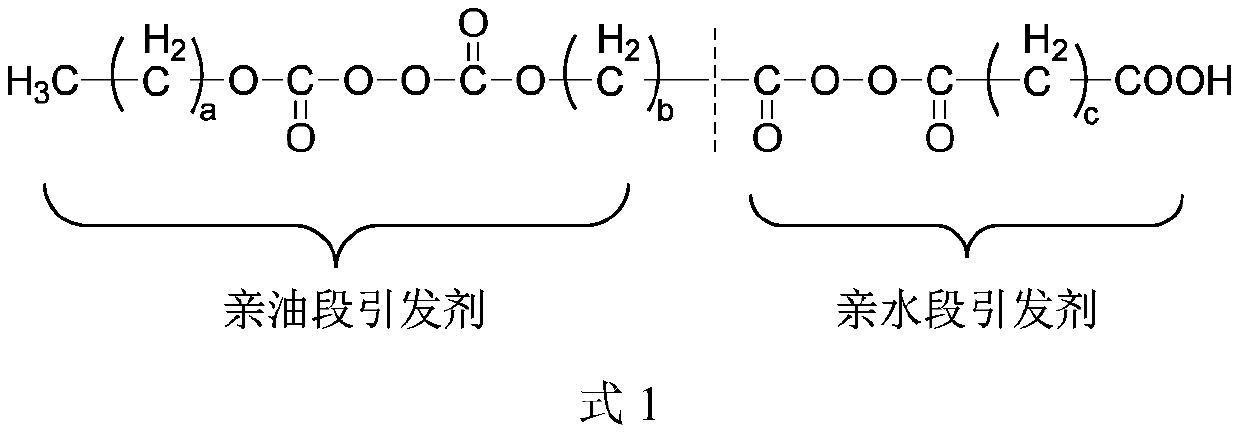

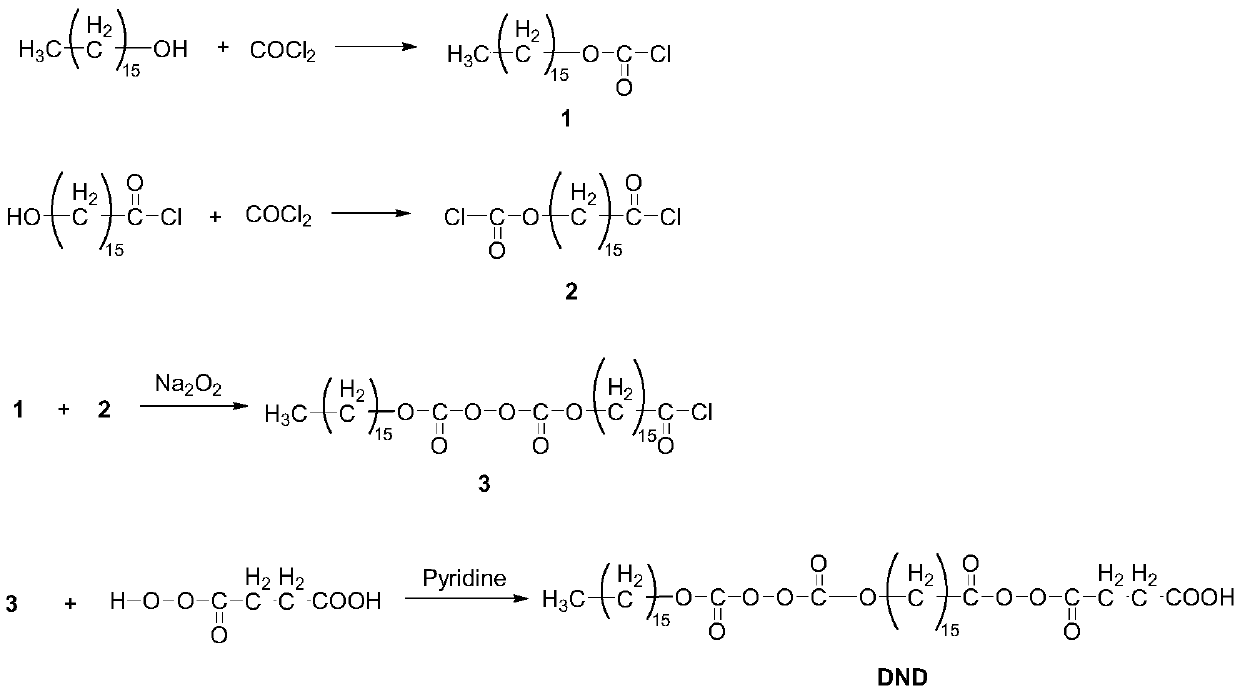

[0050] The preparation method of DND is as follows:

[0051]

[0052] The preparation method of amphiphilic peroxide initiator (DND) is to dissolve n-hexadecanol in dichloromethane, add liquid phosgene at a molar ratio of 1:1 and react at low temperature (control the reaction temperature -3~-5°C) for 8 Compound 1 is generated in 1 hour; hydroxy acid chloride is dissolved in dichloromethane, and liquid phosgene is added in a molar ratio of 1:1 to react at low temperature (control the reaction temperature -3 ~ -5°C) for 8 hours to generate compound 2; compound 1, compound 2 Dissolve in dichloromethane, react with sodium peroxide at 5°C for 24 hours to generate compound 3; dissolve compound 3 and monoperoxysuccinic acid in anhydrous ether and react for 15 hours in the presence of pyridine acid-binding agent to generate amphiphilic Peroxide initiator (DND).

[0053] testing method:

[0054] Various properties of the thermally expandable microspheres prepared in the following ...

Embodiment 1

[0067] In 800g of deionized water, add 40g of colloidal silicon dioxide with an active ingredient of 30%, 1g of KURARAY POVAL48-80 and 1g of DND, and stir the resulting mixture evenly to obtain an aqueous dispersion medium. Mix 100 g of acrylonitrile, 40 g of methacrylonitrile, 50 g of methyl methacrylate, 10 g of methacrylic acid, 0.2 g of ethylene glycol dimethacrylate, and 70 g of isopentane, and mix uniformly to prepare an oil phase mixture.

[0068] The aqueous dispersion medium and the oily mixture were mixed, and the resulting mixed solution was dispersed at a rotation speed of 7000 rpm for 10 minutes using a homomixer (manufactured by PRIMIX, TK homomixer) to prepare a suspension. The suspension was transferred into a pressurized reactor with a capacity of 2.0 L, and after nitrogen replacement, the reaction initial pressure was set at 0.5 MPa, stirred at 500 rpm, and polymerized at a reaction temperature of 70° C. for 8 hours, and the resulting product was filtered and ...

Embodiment 2~8

[0070] The specific steps are as in Example 1, and the amount of raw materials is adjusted, as shown in Tables 1 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com