Quick-patching cold-compressing nano-gel, prepared method thereof and quick-patching cold-compressing nano-gel patch

A cold compress gel paste, nanotechnology, applied in the field of nano-speed cold compress gel and its preparation, nano-speed cold compress gel paste, can solve the problems of slow onset, short duration, long use time, etc., to achieve effective The effect of stable ingredients, high permeability and absorption rate, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

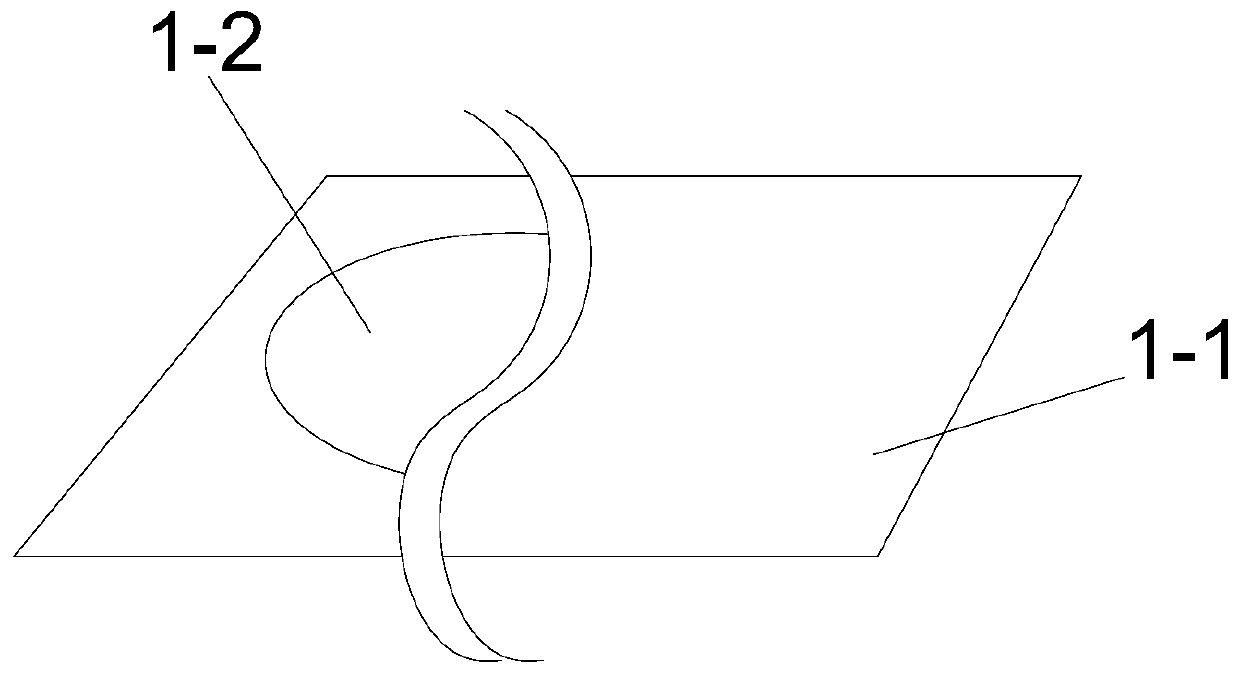

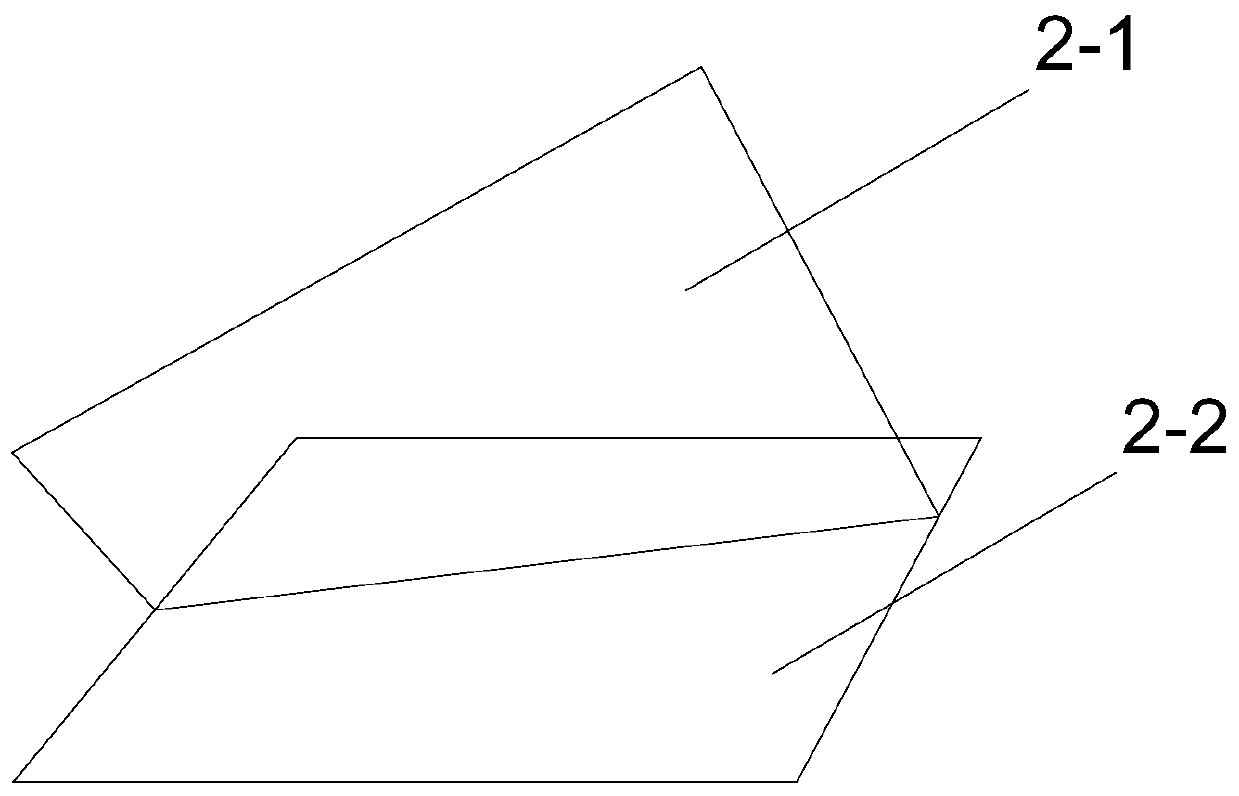

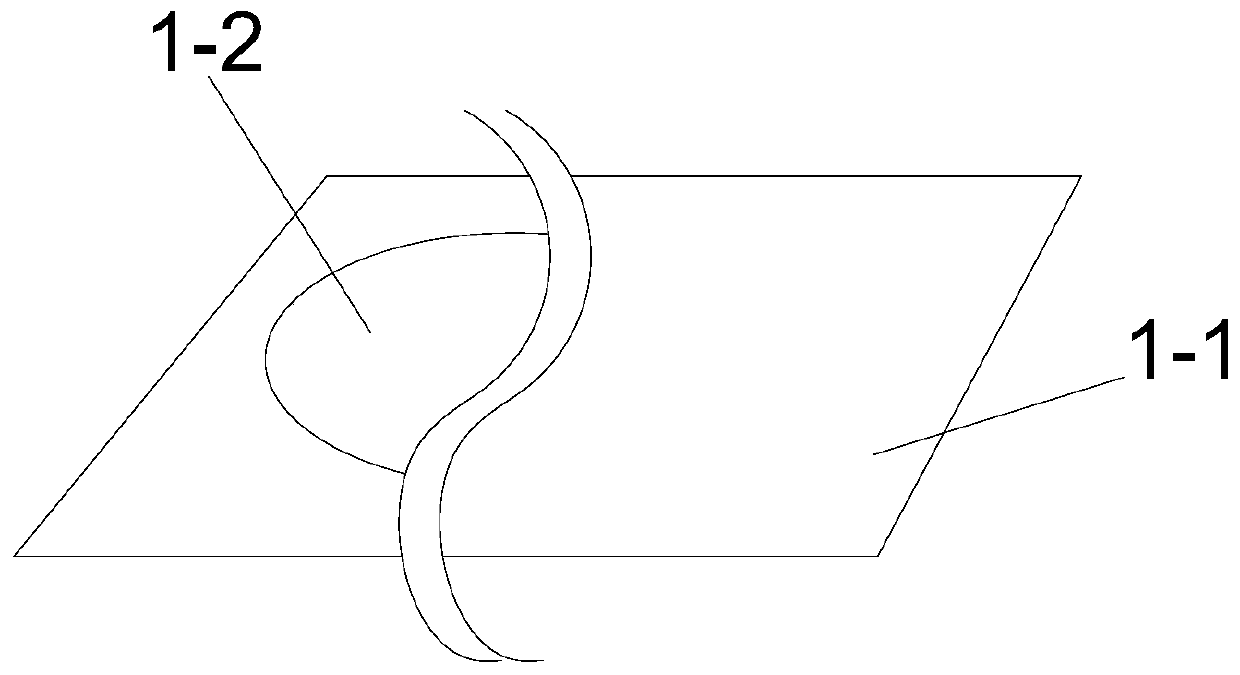

Image

Examples

Embodiment 1

[0027] The nano-quick cold compress gel of the present embodiment, the raw material comprises the following components by weight: peppermint extract 20g, wintergreen extract 10g, white fungus extract 30g, castor oil 40g; described peppermint extract, wintergreen extract and white fungus The form of the extract is powder, and the particle size of the powder is 2nm-6nm;

[0028] The preparation method of the nano-quick cold compress gel of the present embodiment comprises the following steps:

[0029] Step 1, preparing peppermint extract, wintergreen extract and white fungus extract by conventional water extraction and spray drying;

[0030] Step 2, the peppermint extract, wintergreen extract and white fungus extract are all processed by conventional supramolecular technology to obtain a powder with a particle size of 2nm to 6nm, and mixed uniformly;

[0031] Step 3, wrapping the mixed powder in step 2 with castor oil and a surfactant by conventional water-in-oil treatment to o...

Embodiment 2

[0033] The nano-quick cold compress gel of the present embodiment, the raw material comprises the following components by weight: peppermint extract 15g, wintergreen extract 12g, white fungus extract 35g, castor oil 30g; described peppermint extract, wintergreen extract and white fungus The form of the extract is powder, and the particle size of the powder is 6nm-9nm;

[0034] The preparation method of the nano-quick cold compress gel of the present embodiment comprises the following steps:

[0035] Step 1, preparing peppermint extract, wintergreen extract and white fungus extract by conventional water extraction and spray drying;

[0036] Step 2, the peppermint extract, wintergreen extract and white fungus extract are all processed by conventional supramolecular technology to obtain a powder with a particle size of 6nm to 9nm, and mixed uniformly;

[0037] Step 3, wrapping the mixed powder in step 2 with castor oil and a surfactant by conventional water-in-oil treatment to o...

Embodiment 3

[0039] The nano-quick cold compress gel of the present embodiment, the raw material comprises the following components by weight: peppermint extract 25g, wintergreen extract 8g, white fungus extract 25g, castor oil 50g; described peppermint extract, wintergreen extract and white fungus The form of the extract is powder, and the particle size of the powder is 9nm-15nm;

[0040] The preparation method of the nano-quick cold compress gel of the present embodiment comprises the following steps:

[0041] Step 1, preparing peppermint extract, wintergreen extract and white fungus extract by conventional water extraction and spray drying;

[0042] Step 2, the peppermint extract, wintergreen extract and white fungus extract are all processed by conventional supramolecular technology to obtain a powder with a particle size of 9nm to 15nm, and mixed uniformly;

[0043] Step 3, wrapping the mixed powder in step 2 with castor oil and a surfactant by conventional water-in-oil treatment to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com