Biodegradable polyester elastomer and preparation method thereof

A biodegradable polyester and elastomer technology, applied in the field of polymer materials, can solve the problems of difficult to achieve multi-component effective copolymerization, thermal degradation, low product molecular weight, insufficient esterification rate, etc., to reduce thermal degradation and crossover The effects of side effects, high biodegradability, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

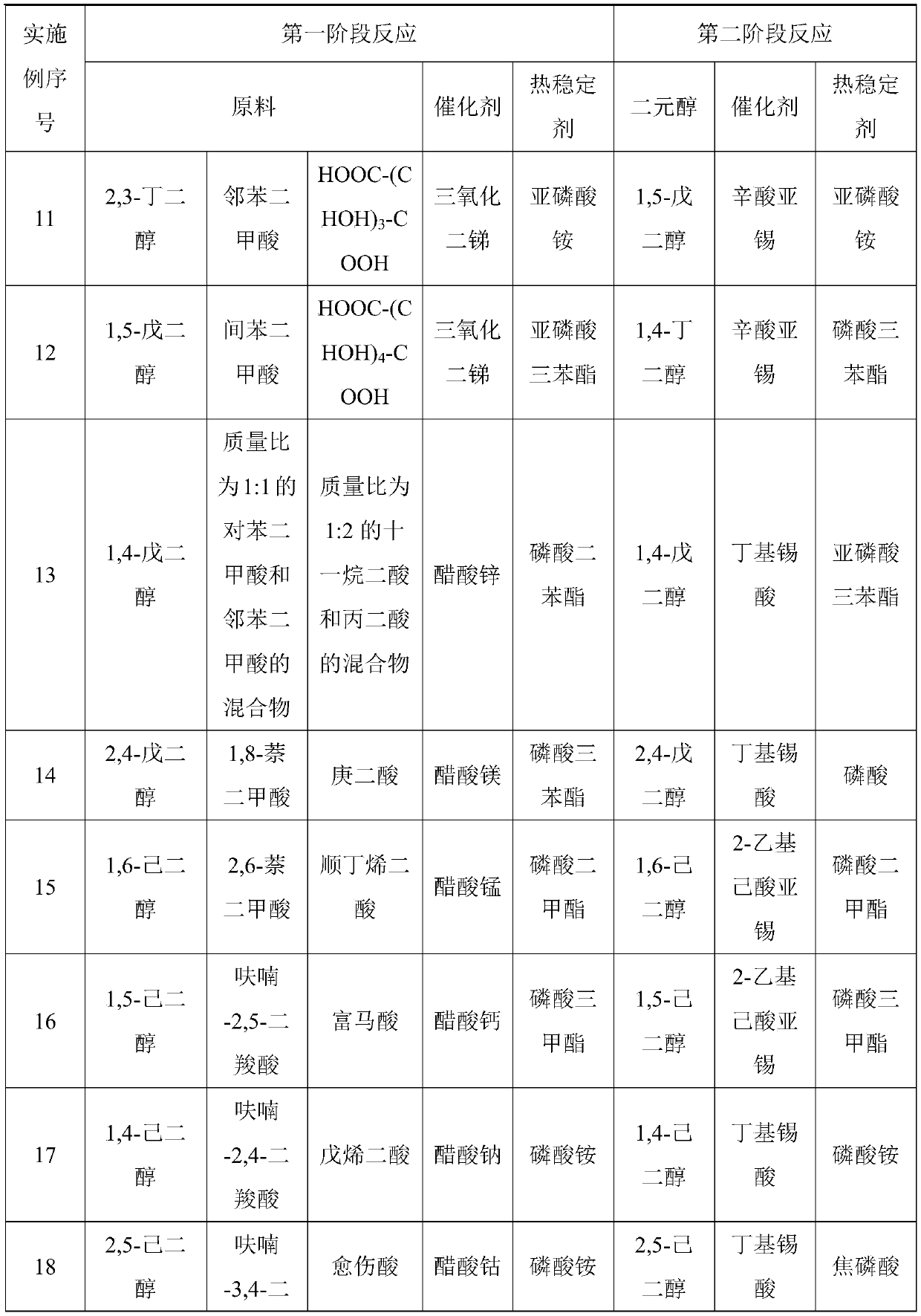

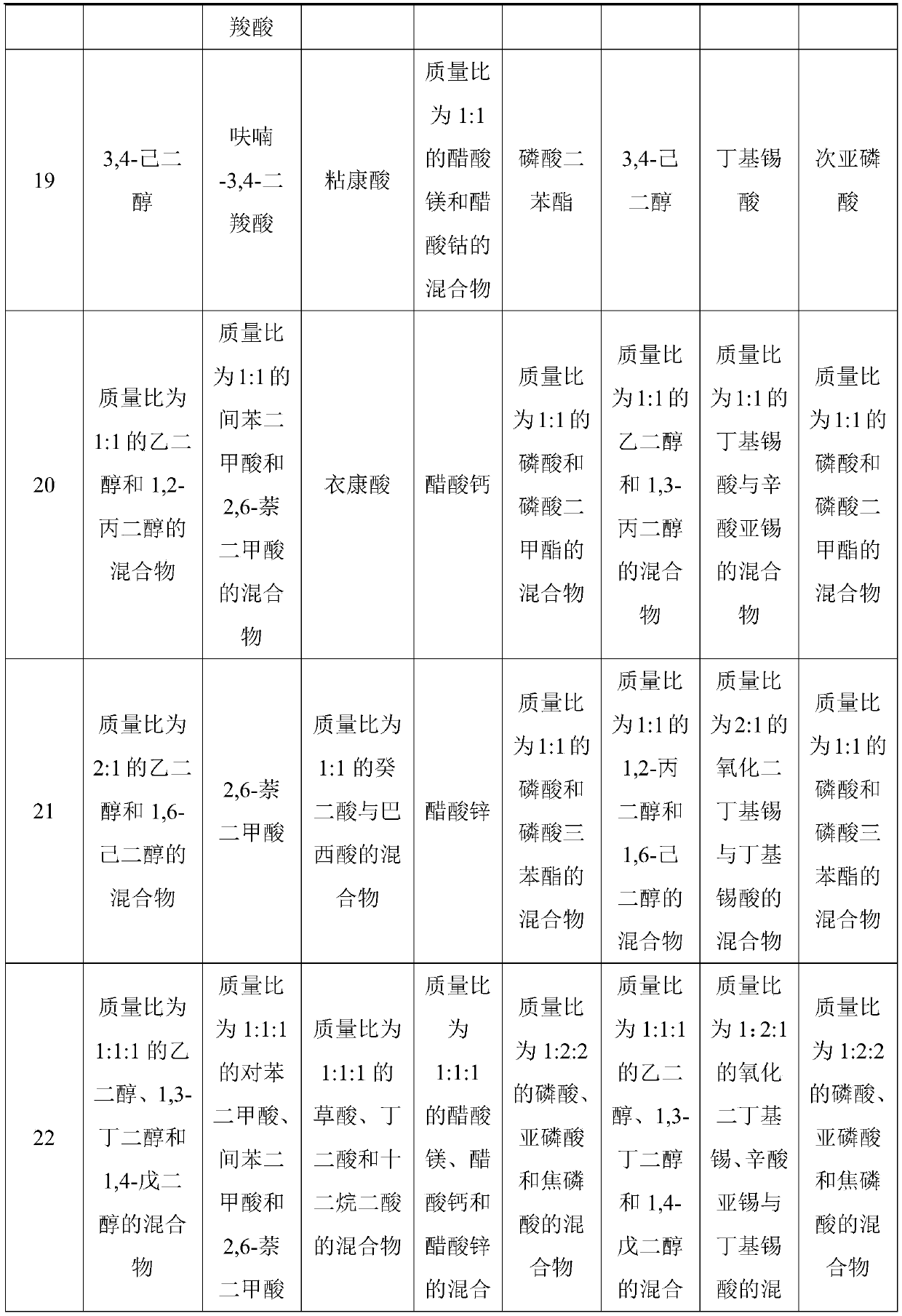

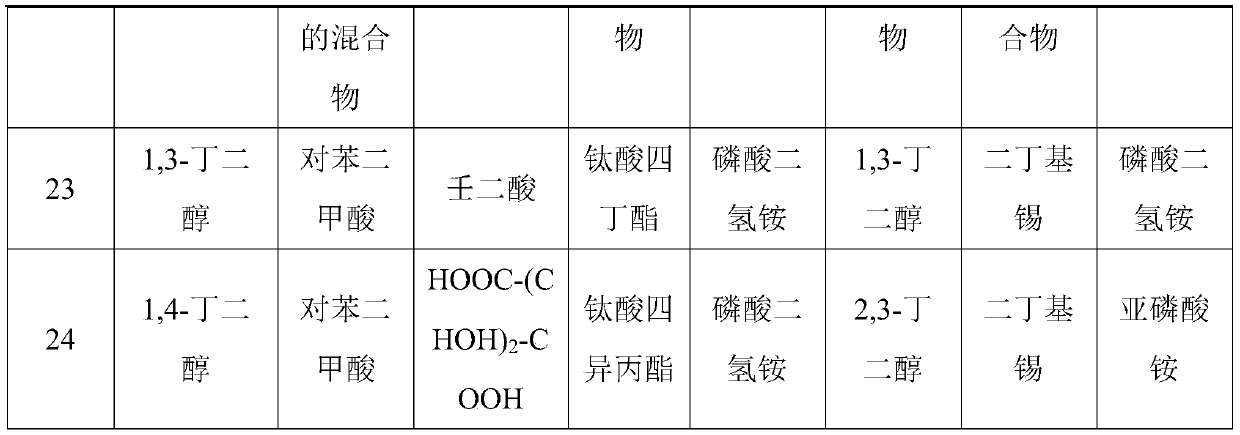

Examples

Embodiment 1

[0039] A kind of biodegradable polyester elastomer, its preparation process is as follows:

[0040] (1) The first stage reaction: using 1,4-butanediol, terephthalic acid and adipic acid as raw materials, adding phosphoric acid and antioxidant 1010 at the same time, under the temperature of 190°C and under the action of tetrabutyl titanate Esterification for 2 hours, followed by prepolymerization for 0.5 hours at a pressure of 0.05 mbar and a temperature of 200° C., wherein the ratio of the molar weight of 1,4-butanediol to the sum of the molar weights of terephthalic acid and adipic acid is 1.1: 1. The ratio of the molar weight of tetrabutyl titanate to the sum of the molar weights of terephthalic acid and adipic acid is 50ppm, and the addition amounts of phosphoric acid and antioxidant 1010 are 1,4-butanediol and terephthalic acid respectively 0.1% and 0.2% of the sum of mass of adipic acid;

[0041] (2) The second stage reaction: take the first stage product, IIDCA, 1,4-but...

Embodiment 2

[0057] A kind of biodegradable polyester elastomer, its preparation process is as follows:

[0058] (1) The first-stage reaction: using 1,4-butanediol, terephthalic acid and suberic acid as raw materials, adding phosphoric acid and antioxidant 1010 at the same time, at a temperature of 190 ° C and the effect of tetrabutyl titanate Under the conditions of esterification for 2 hours, prepolymerization for 0.5 hours under the pressure of 100mbar and temperature of 200°C, the ratio of the molar weight of 1,4-butanediol to the sum of the molar weights of terephthalic acid and suberic acid is 1.1 : 1, the ratio of the molar weight of tetrabutyl titanate to the sum of the molar weight of terephthalic acid and suberic acid is 50ppm, and the addition amount of phosphoric acid and antioxidant 1010 is respectively 1,4-butanediol, terephthalic acid 0.1% and 0.2% of the mass sum of dicarboxylic acid and suberic acid;

[0059] (2) The second-stage reaction: using the first-stage product, I...

Embodiment 3

[0066] A kind of biodegradable polyester elastomer, its preparation process is as follows:

[0067] (1) The first stage reaction: 1,3-propanediol, dimethyl isophthalate and dimethyl malonate are used as raw materials, and phosphorous acid (heat stabilizer) and antioxidant 1076 are added at the same time, at a temperature of 215°C Esterification under the condition of tetraisopropyl titanate for 2.5h, followed by prepolymerization at 0.7mbar pressure and temperature of 220°C for 1h, wherein the molar amount of 1,3-propanediol is equal to that of dimethyl isophthalate The ratio of the molar weight of tetraisopropyl titanate to the sum of the molar weights of dimethyl malonate and dimethyl malonate is 1.2:1, and the ratio of the molar weight of tetraisopropyl titanate to the sum of the molar weights of dimethyl isophthalate and dimethyl malonate The amount of phosphorous acid and antioxidant 1076 added is 0.3% and 0.1% of the sum of the mass of 1,3-propanediol, dimethyl isophthal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com