Reaction recovery system for continuous synthesis of polyamide and method thereof

A recovery system and technology of polyamide, applied in the field of continuous synthesis method and reaction recovery system of polyamide, can solve the problems of complex structure and uncontrollable pressure, achieve low energy demand, promote upgrading, equipment investment and maintenance expenses less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

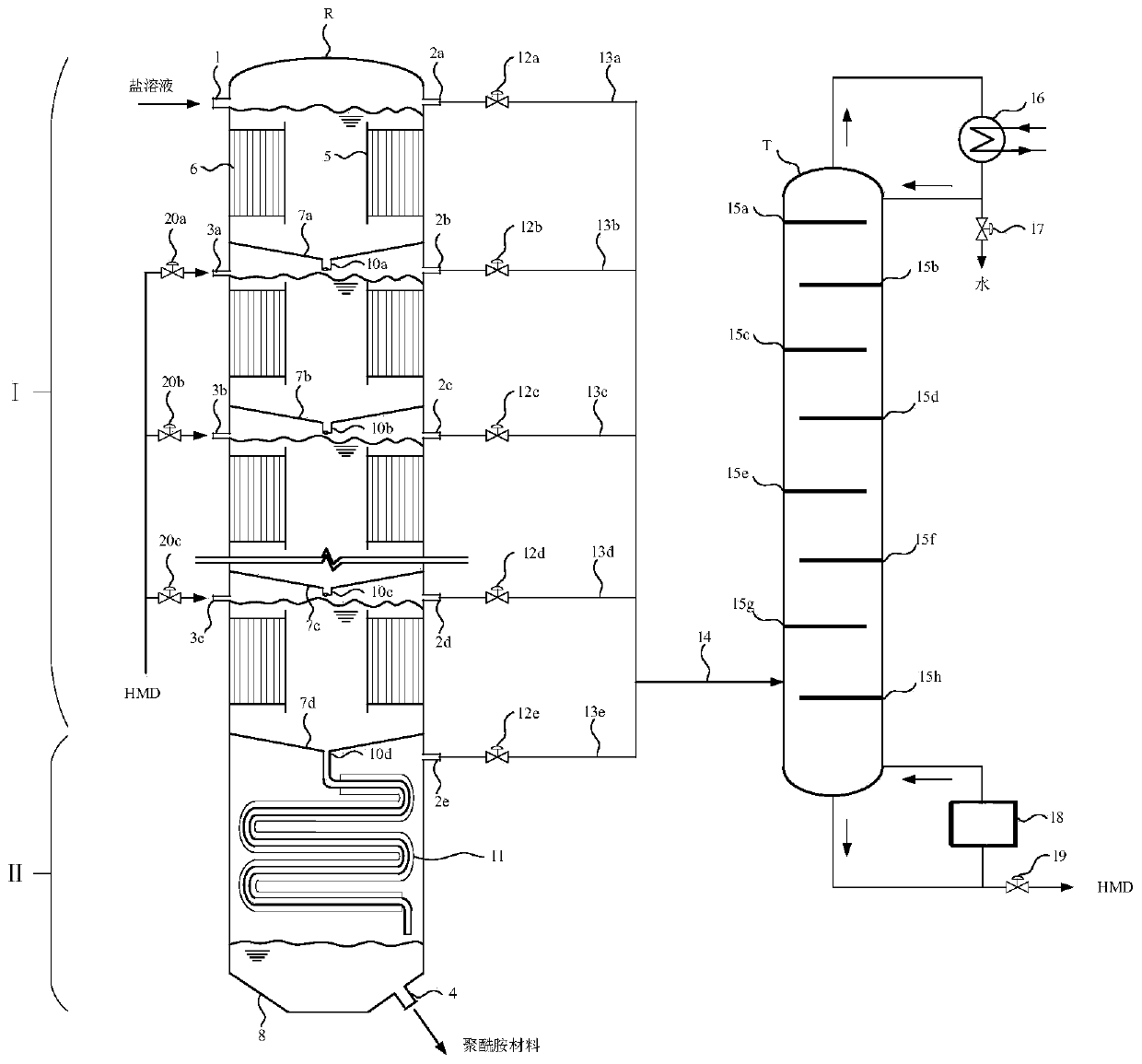

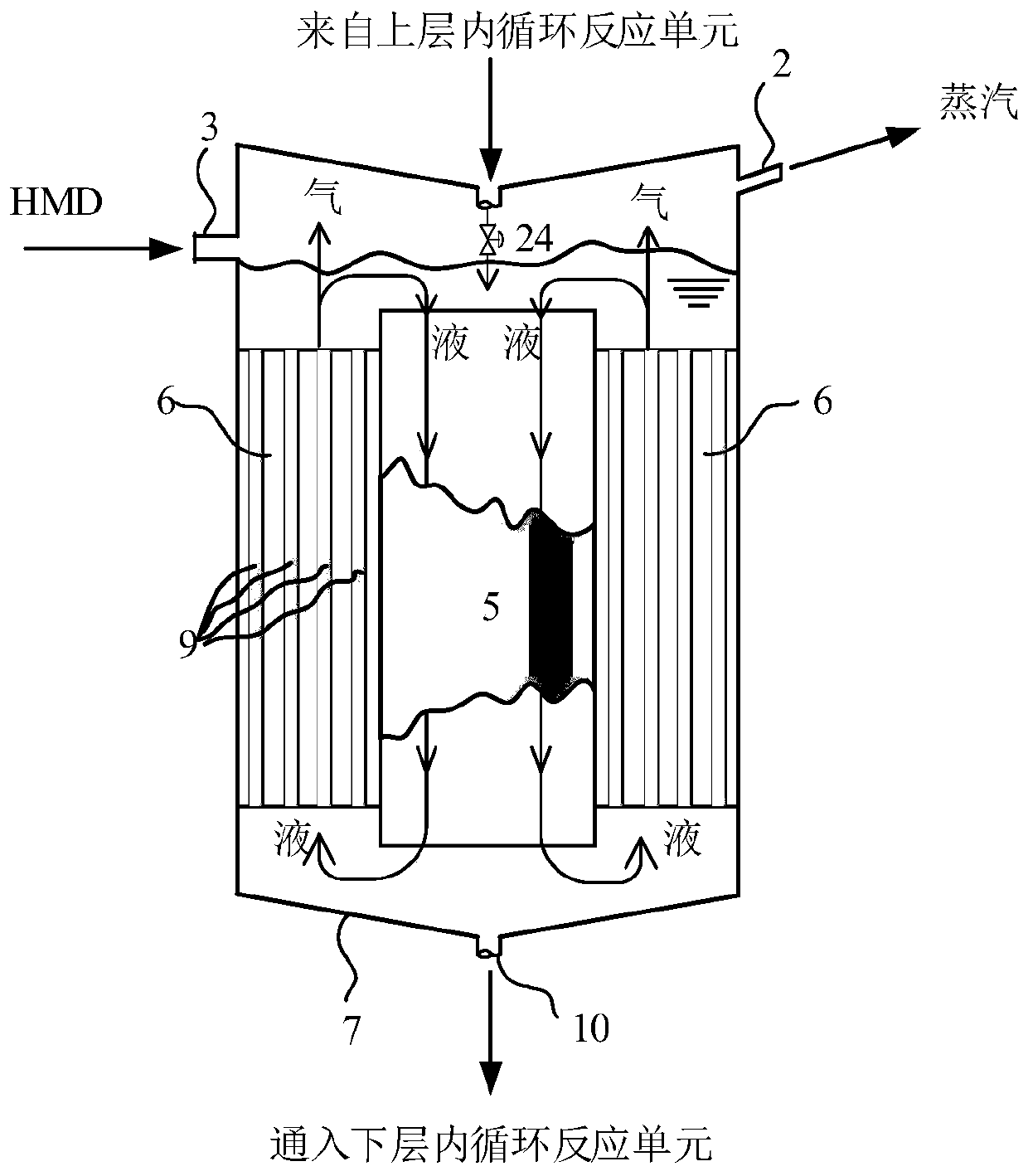

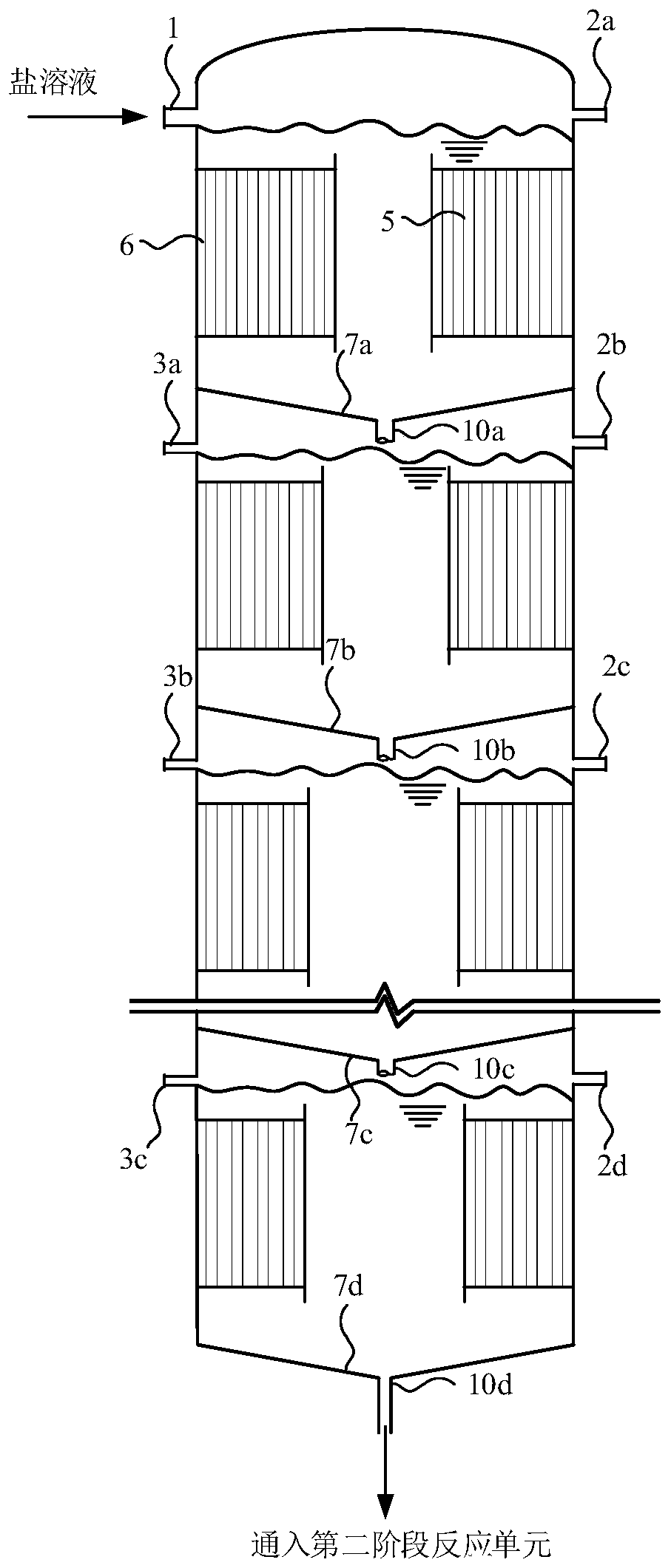

[0045] A nylon 66 salt solution with a temperature of 215°C and a concentration of 69wt% was injected into the multi-stage internal circulation tower reactor. The temperature of the first-stage reaction unit in the first stage of the reaction was controlled at 216°C, and the pressure was controlled at 16atm through the steam outlet valve. The reaction materials pass through 6-stage reaction units. The ratio of the diameter of the guide tube to the diameter of the tower in each stage of the reaction unit is 0.3:1, 0.35:1, 0.4:1, 0.5:1, 0.6:1 and 0.7:1. The operating temperature Gradually increase the temperature to 230°C and decrease the pressure to 12 atm. The reaction material is injected into the second stage to continue the reaction. The second stage consists of two sets of decompression units including serpentine decompression tubes arranged horizontally. The operating temperature is gradually increased from 238°C to 260°C, and the operating pressure is reduced to 6atm. Th...

Embodiment 2

[0047]A nylon 66 salt solution with a temperature of 200°C and a concentration of 60wt% is injected into the multi-stage internal circulation tower reactor. The temperature of the first layer of the reaction unit in the first stage of the reaction is controlled at 216°C and the pressure is 15atm. The reaction materials pass through 7 layers of circulating reaction units, and the ratio of the diameter of the guide cylinder to the diameter of the tower of each reaction unit is 0.3:1, 0.35:1, 0.4:1, 0.45:1, 0.5:1, 0.6:1 and 0.7 : 1. The operating temperature gradually increased to 232°C and the pressure decreased to 11atm. The reaction material is injected into the second stage to continue the reaction. The second stage consists of two sets of decompression units including vertically arranged serpentine decompression pipes. The operating temperature is gradually increased from 236°C to 260°C, and the operating pressure is reduced to 2atm. The diamine recovery tower adopts plate r...

Embodiment 3

[0049] A nylon 66 salt solution with a temperature of 220°C and a concentration of 70wt% was injected into the multi-stage internal circulation tower reactor. The temperature of the first-stage reaction unit in the first stage of the reaction was controlled at 216°C, and the pressure was controlled at 16 atm through the steam outlet valve. The reaction materials pass through two stages of reaction units. The ratio of the diameter of the guide tube to the diameter of the tower of each reaction unit is 0.3:1 and 0.7:1 in turn. The operating temperature is gradually raised to 230°C and the pressure is reduced to 12atm. The reaction material is injected into the second stage to continue the reaction. The second stage consists of 5 sets of decompression units including serpentine decompression pipes arranged horizontally. The operating temperature is gradually increased from 235°C to 265°C, and the operating pressure is reduced to 1 atm. The diamine recovery tower adopts plate recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com