A kind of pyridyl-containing 1,3,4-oxadiazole water-soluble fluorescent polymer and its synthesis method

A technology of oxadiazole groups and fluorescent monomers, which is applied in the field of circulating water treatment agents, can solve the problems of complex post-purification treatment process, unfavorable safety and environmental protection, and numerous synthesis reaction steps, so as to achieve a safe and environmentally friendly synthesis process. Excellent water solubility and easy industrial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

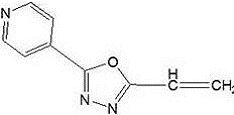

[0023] Example 1 (synthesis of unsaturated fluorescent monomers containing 1,3,4-oxadiazole groups)

[0024] (1) At room temperature, add 75.0g of acrylic acid with a mass content >99.5% and 129.6g of 4-formylhydrazinopyridine (molar ratio is about 1:1) into a 1000mL three-neck reactor with a drying device;

[0025] (2) Connect the reactor to the vacuum pump and maintain the pressure state of the system at -0.03 ~-0.04MPa, add 400.0g of phosphorus oxychloride after distillation and drying, and react under stirring conditions at 78±2°C under micro-reflux 7.5 hours until the system is yellow-brown uniform and transparent;

[0026] (3) Keep the vacuum of the system within the range of -0.01~-0.02MPa, distill under reduced pressure until no liquid is distilled out of the system, distill out and recover 221.7g of phosphorus oxychloride, quickly add 480g of ice-water mixture to the kettle and use 30% hydrogen Sodium oxide aqueous solution adjusts the pH value of the system to 8.5~9...

Embodiment 2

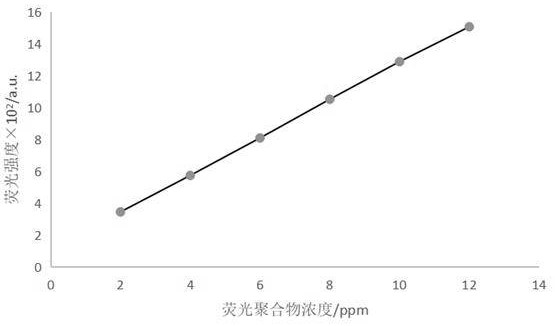

[0032] At 60±2°C, dissolve 72g of maleic anhydride in 60g of deionized water, mix well and pour into the monomer dropping tank for later use; according to m 荧光单体 :m AA :m MA = 0.012:1:0.40 ratio, respectively weigh 2.16g of the fluorescent monomer synthesized in the above embodiment 1, 50g of isopropanol, 200g of deionized water, 22.1g of hydrogen peroxide aqueous solution and 180g of acrylic acid with a mass percentage content of 27.5%. Put into the kettle in sequence according to a certain mass ratio; add a certain amount of sodium hydroxide aqueous solution to adjust the pH value and control the pH value of the system to 4.5; raise the temperature to a reflux state, drop monomers to initiate polymerization, and maintain the pH value of the system within the range of 4.0~4.5 , after the addition of the monomer was completed, the insulation reaction was carried out for 1 hour, the isopropanol was evaporated under negative pressure for recycling, and the temperature was lower...

Embodiment 3

[0034] Dissolve 150g of maleic anhydride in 100g of deionized water at 55±2°C, mix well and pour into the monomer dropping tank for later use; 荧光单体 :m AA :m MA= 0.020:1:0.30 ratio, respectively weigh 10.0g of the fluorescent monomer synthesized in the above embodiment 1, 120g of isopropanol, 1000g of deionized water, 50.8g of hydrogen peroxide aqueous solution and 500g of acrylic acid with a mass percentage content of 27.5% Put into the kettle in sequence according to a certain mass ratio; raise the temperature to the reflux state, drop the monomer to initiate polymerization, maintain the pH value of the system in the range of 4.0~4.5, after the monomer is added dropwise, keep the reaction for 1.5 hours, and steam out the isopropyl under negative pressure Alcohol recycling, cooling down and adding water to dilute to obtain 1618.21g of a yellow fluorescently labeled MA-AA copolymer sodium salt solution with an active content of 40.61%. After testing, the viscosity-average mole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com