A kind of microemulsion type coal slime flotation collector and preparation method thereof

A coal slime flotation and collector technology, applied in flotation, solid separation, etc., can solve the problems of poor harvesting effect, high freezing point, and environmental pollution in winter, and achieve the goal of not easy to break emulsion, easy to disperse, and environment-friendly The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

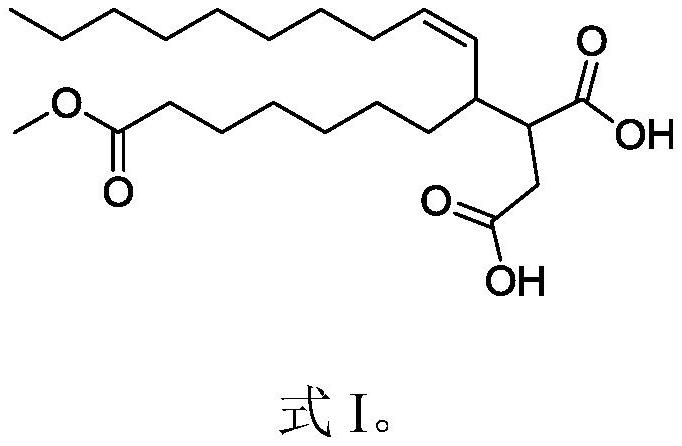

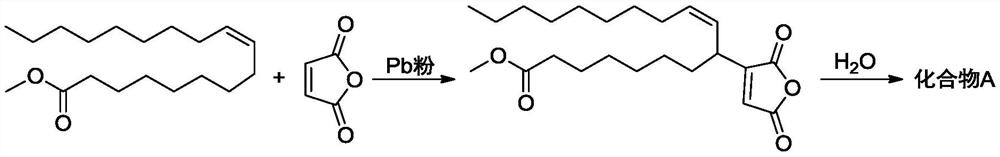

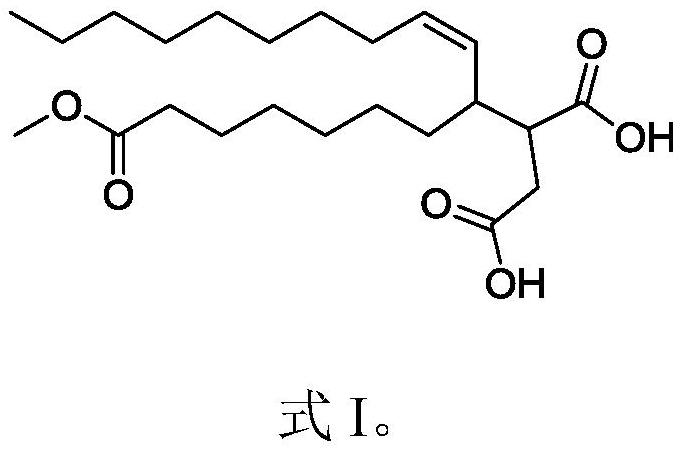

[0044] A preparation method of compound A, comprising the following steps:

[0045]1) Add methyl oleate and a catalytic amount of Pb powder into the reaction vessel, preheat to 150°C, and slowly add maleic anhydride at the molar ratio of maleic anhydride to methyl oleate 1:1.008 After uniform dispersion, the temperature was raised to 160°C for 3-4 hours to obtain an intermediate product;

[0046] 2) The intermediate product material in step 1) was filtered while it was hot to remove the catalyst, and 4.5 wt% of water was added to the total amount of the intermediate product, stirred, and hydrolyzed at 60° C. for 2-3 hours to obtain compound A. Compound A is a yellow oily liquid at room temperature.

Embodiment 2

[0048] A kind of microemulsion type coal slime flotation collector, is made by the weight ratio of compound A and compound emulsifier by 90:10; Wherein, compound emulsifier is made of propylene glycol fatty acid ester: sorbitan laurate : Polyoxyethylene oxypropylene oleate is composed of 1.5:1:8.5 weight ratio;

[0049] The preparation method of this microemulsion type coal slime flotation collector comprises the following steps:

[0050] 1) Take propylene glycol fatty acid ester: sorbitan laurate: polyoxyethylene oxypropylene oleate in a weight ratio of 1.5:1:8.5, and mix them evenly to obtain a compound emulsifier;

[0051] 2) Add the compound emulsifier and compound A into the container, add 4 times the volume of water, and stir at a speed of 100r / min for 3min to form a coarse emulsion;

[0052] 2) The coarse emulsion is placed in an ultrasonic cleaning tank for emulsification for 5 minutes to obtain a microemulsion type coal slime flotation collector.

Embodiment 3

[0054] A kind of microemulsion type coal slime flotation collector, is made by the weight ratio of compound A and compound emulsifier by 90:10; Wherein, compound emulsifier is made of propylene glycol fatty acid ester: sorbitan laurate : Polyoxyethylene castor oil is composed at a weight ratio of 1:1:8;

[0055] The preparation method of this microemulsion type coal slime flotation collector comprises the following steps:

[0056] 1) Take propylene glycol fatty acid ester: sorbitan laurate: polyoxyethylene castor oil in a weight ratio of 1:1:8, and mix evenly to obtain a compound emulsifier;

[0057] 2) Add the compound emulsifier and compound A into the container, add 4 times the volume of water, and stir at a speed of 150r / min for 3min to form a coarse emulsion;

[0058] 2) Place the coarse emulsion in an ultrasonic cleaning tank for emulsification for 7 minutes to obtain a microemulsion type coal slime flotation collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com