Lithium ion battery negative electrode slurry as well as preparation method and application thereof

A technology of lithium ion battery and negative electrode slurry, which is applied in the field of lithium ion battery, can solve the problems of insufficient mixing of polyvinylidene fluoride, limited surface tension of solvent, strong special type of negative electrode material, etc., and achieves increased adhesion and electrical performance. Improve and reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

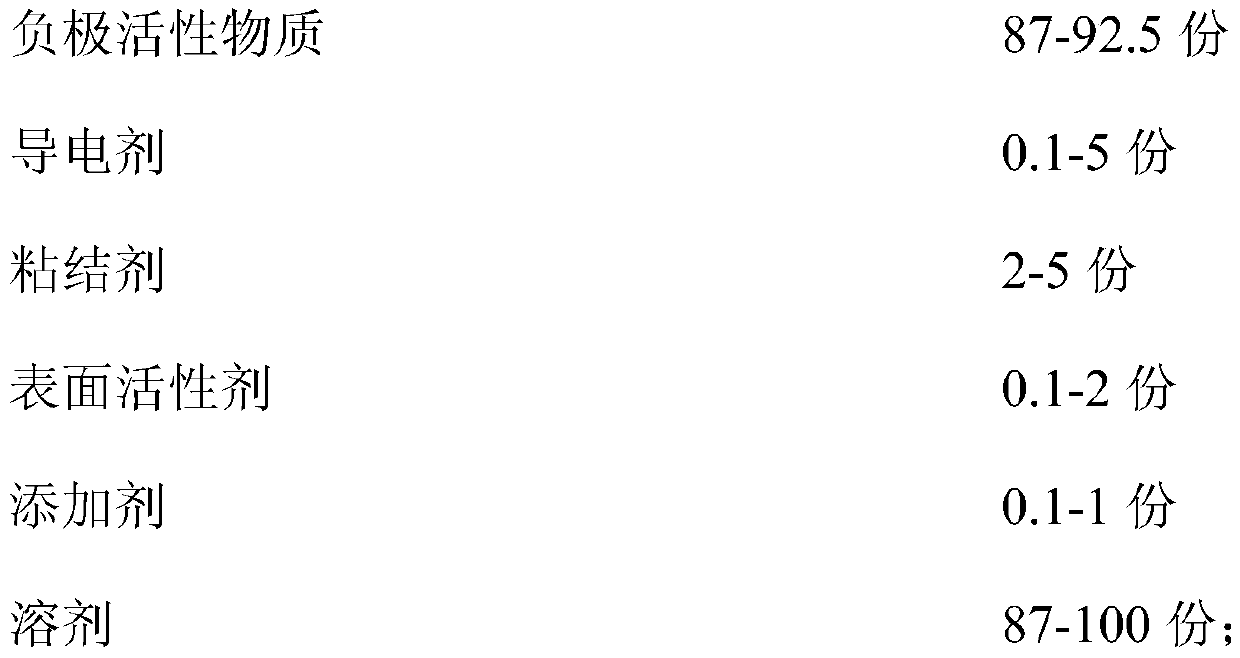

[0065] The negative electrode slurry described in this embodiment comprises the following components in parts by weight:

[0066]

[0067]

[0068] Wherein, the negative electrode active material is composed of hard carbon and graphite with a mass ratio of 1:1;

[0069] The conductive agent is SP; the surfactant is EC, the additive is oxalic acid, the binder is polyvinylidene fluoride, and the solvent is N-methylpyrrolidone;

[0070] The preparation method of negative electrode slurry described in this embodiment comprises the following steps:

[0071] (1) Glue making: Mix 5 parts of binder and 57.5 parts of solvent, stir for 3 hours at a linear speed of 8 m / s to obtain glue, and leave it to stand for use;

[0072] (2) Mixing: 87 parts of negative electrode active material, 5 parts of conductive agent and 2 parts of surfactant were mixed, and the mixture was mixed for 2 hours under the condition that the line speed was 1m / s to obtain the mixed material;

[0073] (3) Kn...

Embodiment 2

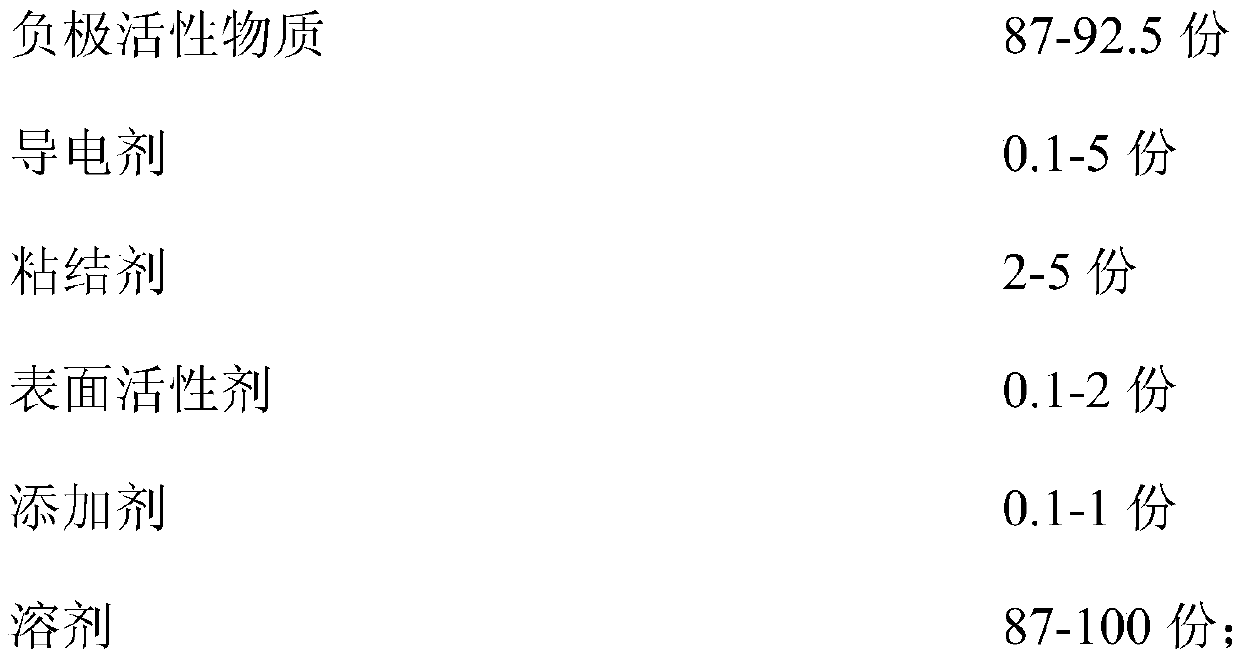

[0081] The negative electrode slurry described in this embodiment comprises the following components in parts by weight:

[0082]

[0083] Among them, the negative electrode active material is composed of hard carbon, graphite and soft carbon with a mass ratio of 2:1:1; the conductive agent is graphene; the surfactant is DEC, the additive is citric acid, the binder is polyvinylidene fluoride, and the solvent Is N-methylpyrrolidone;

[0084] The preparation method of negative electrode slurry described in this embodiment comprises the following steps:

[0085] (1) Glue making: Mix 4.4 parts of binder and 50.6 parts of solvent, stir for 3 hours at a linear speed of 10 m / s to obtain glue, and leave it to stand for use;

[0086] (2) Mixing: 92.5 parts of negative electrode active material, 0.1 part of conductive agent and 2 parts of surfactant were mixed, and the mixture was mixed for 2 hours under the condition that the linear speed was 1m / s to obtain the mixture;

[0087] (...

Embodiment 3

[0095] The negative electrode slurry described in this embodiment comprises the following components in parts by weight:

[0096]

[0097] Among them, the negative electrode active material is composed of graphite; the conductive agent is a mixture of graphene and KS-6 with a mass ratio of 1:1; the surfactant is a mixture of EC and DEC with a mass ratio of 1:1, and the additive is composed of It is made of 1:1 mixture of oxalic acid and citric acid, the binder is polyvinylidene fluoride, and the solvent is N-methylpyrrolidone;

[0098] The preparation method of negative electrode slurry described in this embodiment comprises the following steps:

[0099] (1) Glue making: Mix 3 parts of binder and 34.5 parts of solvent, stir for 3 hours at a linear speed of 8m / s to obtain glue, and let it stand for use;

[0100] (2) Mixing: 90 parts of negative electrode active material, 5 parts of conductive agent and 1 part of surfactant were mixed, and the mixture was mixed for 2 hours und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com