Progress regulation method of automotive high-formability aluminum alloy heterogeneous structure

A formability and aluminum alloy technology, which is applied in the field of process regulation of high formability aluminum alloy heterostructure for automobiles, can solve the problems of limited improvement in stamping performance of alloy sheets, complex thermal processing process routes, and high production costs, and achieve Elimination of high-temperature and long-term homogenization heat treatment process, improved stamping performance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

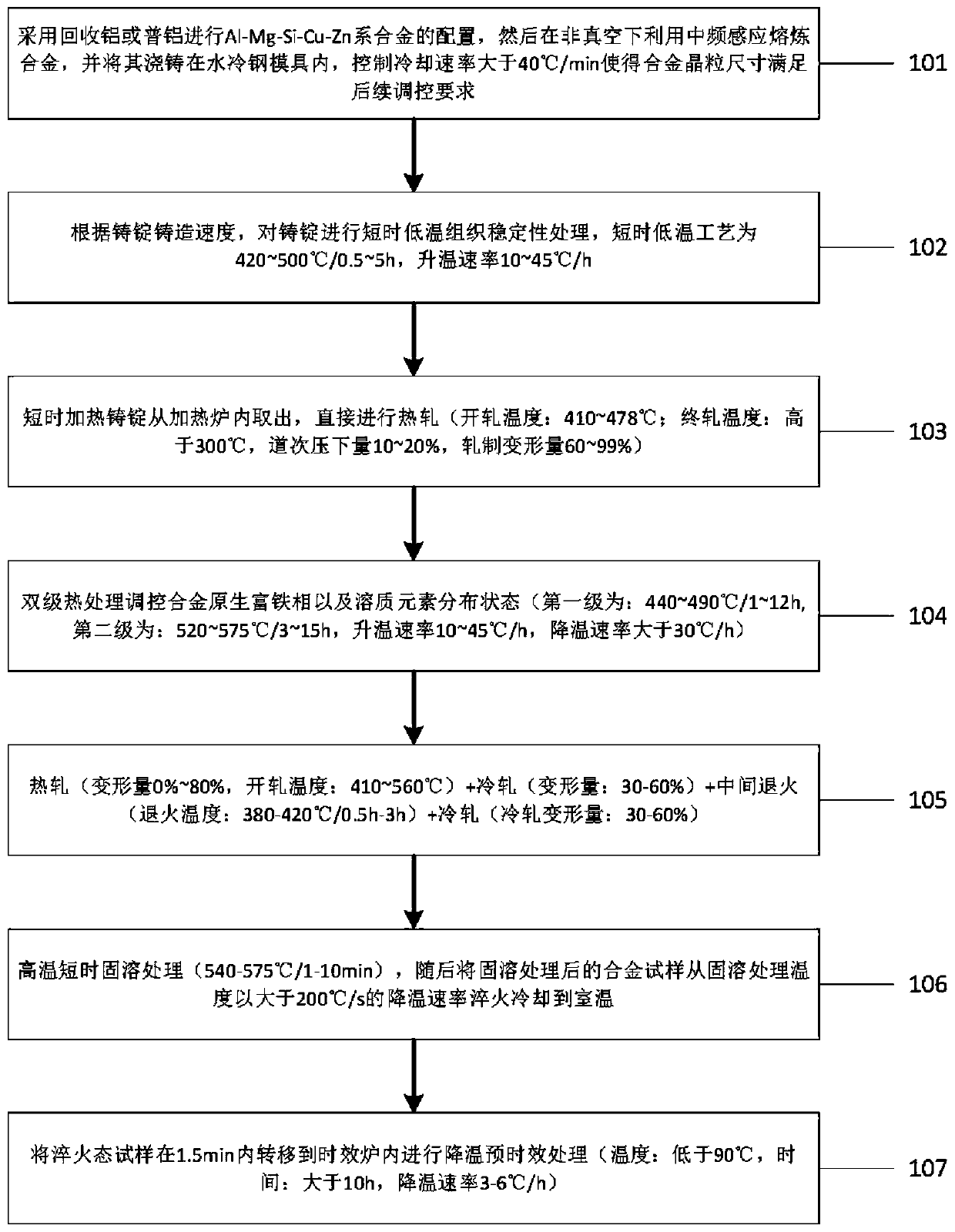

Method used

Image

Examples

Embodiment 1

[0051]Implementation of the invention Alloy 1# adopts the following intermediate frequency induction melting and casting method. First, all the pure aluminum is added to the crucible and melted. 10wt% Cr, Al-10wt% Ti master alloy, after melting, add Al-50wt% Cu and Al-20wt% Si and other master alloys respectively, then stir the melt with high power for 5min, and then control the temperature above 720°C, Add pure Zn and pure Mg respectively, and press them into the bottom of the melt with a graphite bell jar when adding, take out the bell jar after it is completely melted, adjust the power of the intermediate frequency induction furnace to re-stabilize the temperature of the alloy melt at 740°C, and then remove the slag 1. Add refining agent for degassing and refining; then add Al-5wt%Ti-1wt%B grain refiner when the temperature of the melt is reduced to about 720°C and carry out proper stirring, and finally heat the melt at this temperature for 10 minutes Casting into a steel m...

Embodiment 2

[0053] Implementation of the invention Alloy 1# adopts the following intermediate frequency induction melting and casting method. First, all the pure aluminum is added to the crucible and melted. 10wt% Cr, Al-10wt% Ti master alloy, after melting, add Al-50wt% Cu and Al-20wt% Si and other master alloys respectively, then stir the melt with high power for 5min, and then control the temperature above 720°C, Add pure Zn and pure Mg respectively, and press them into the bottom of the melt with a graphite bell jar when adding, take out the bell jar after it is completely melted, adjust the power of the intermediate frequency induction furnace to re-stabilize the temperature of the alloy melt at 740°C, and then remove the slag 1. Add refining agent for degassing and refining; then add Al-5wt%Ti-1wt%B grain refiner when the temperature of the melt is reduced to about 720°C and carry out proper stirring, and finally heat the melt at this temperature for 10 minutes Casting into a steel ...

Embodiment 3

[0055] Implementation of the invention Alloy 1# adopts the following intermediate frequency induction melting and casting method. First, all the pure aluminum is added to the crucible and melted. 10wt% Cr, Al-10wt% Ti master alloy, after melting, add Al-50wt% Cu and Al-20wt% Si and other master alloys respectively, then stir the melt with high power for 5min, and then control the temperature above 720°C, Add pure Zn and pure Mg respectively, and press them into the bottom of the melt with a graphite bell jar when adding, take out the bell jar after it is completely melted, adjust the power of the intermediate frequency induction furnace to re-stabilize the temperature of the alloy melt at 740°C, and then remove the slag 1. Add refining agent for degassing and refining; then add Al-5wt%Ti-1wt%B grain refiner when the temperature of the melt is reduced to about 720°C and carry out proper stirring, and finally heat the melt at this temperature for 10 minutes Casting into a steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com