Graphite crucible for vacuum smelting of intermediate frequency furnace and preparation method thereof

A technology for vacuum smelting and graphite crucibles, which is applied in the directions of crucible furnaces, furnaces, furnace types, etc., can solve the problems of low yield and low strength of graphite crucibles, achieve high yield, improve compressive strength and flexural strength, and improve finished products. the effect of improving adhesion and dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

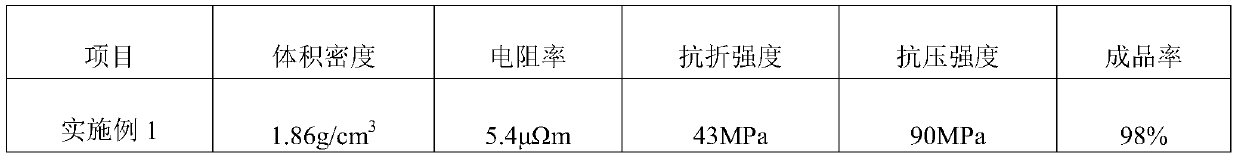

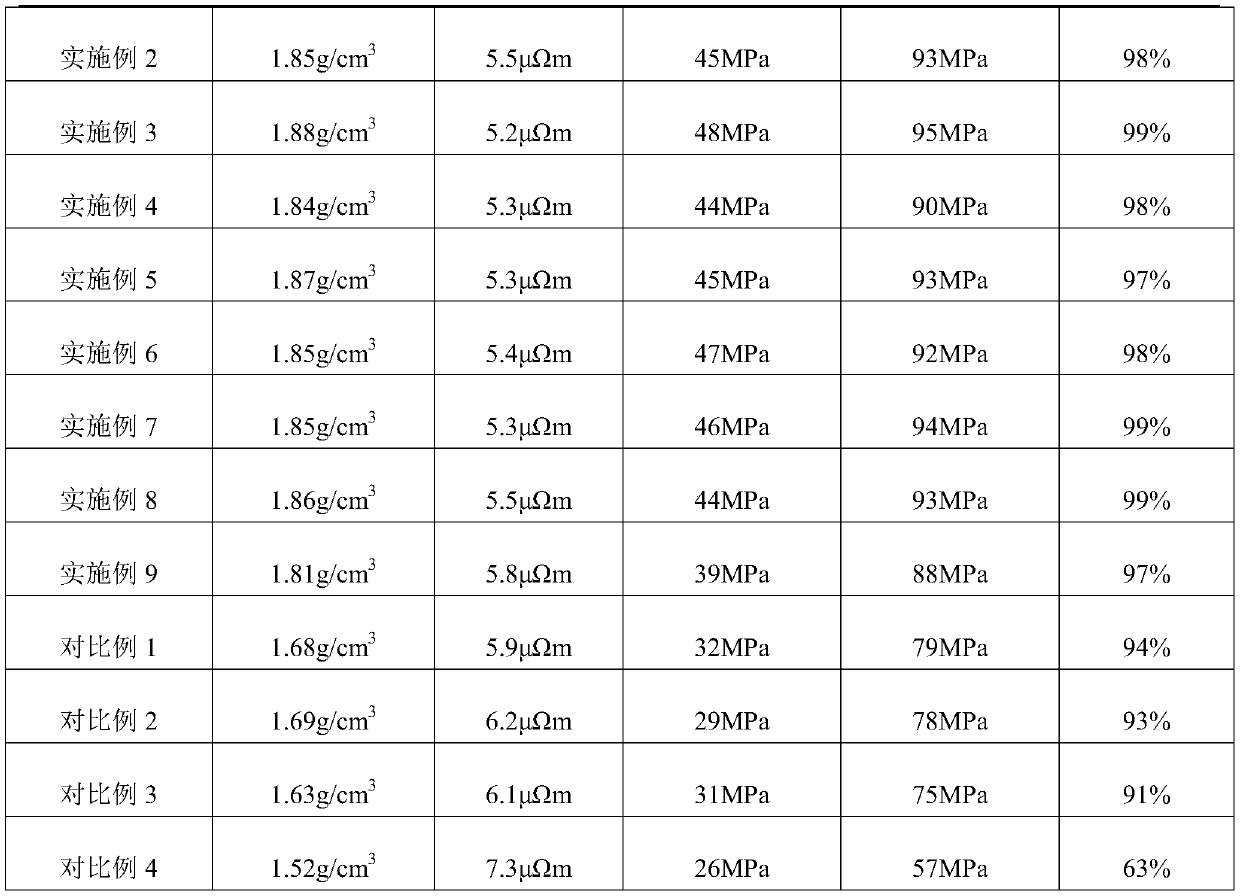

Examples

Embodiment 1

[0035] A graphite crucible for vacuum smelting in an intermediate frequency furnace, comprising the following components in parts by weight:

[0036] 7 parts of needle coke with a particle size of 4-6 mm, 8 parts of needle coke with a particle size of 2-4 mm, 20 parts of needle coke with a particle size of 0-2 mm, 26 parts of needle coke powder, and 7 parts of Sangao graphite. 15 parts of asphalt,

[0037] Among them, needle coke powder is obtained by crushing needle coke and passing through a 200-mesh sieve; Sangao graphite is high-density, high-purity, high-strength graphite with a density of 1.85g / cm 3 , fixed carbon content ≥ 99.9%, flexural strength ≥ 25MPa, compressive strength ≥ 50MPa; the preparation method of modified asphalt is: crush 70 parts of asphalt through a 200-mesh sieve to obtain asphalt powder, and dissolve the asphalt powder in tetrahydrofuran solvent To obtain the tetrahydrofuran solution of asphalt, add 13 parts of nano-silica, 5 parts of chromium oxide...

Embodiment 2

[0046]A graphite crucible for vacuum smelting in an intermediate frequency furnace, comprising the following components in parts by weight:

[0047] 9 parts of needle coke with a particle size of 4-6 mm, 10 parts of needle coke with a particle size of 2-4 mm, 25 parts of needle coke with a particle size of 0-2 mm, 35 parts of needle coke powder, and 12 parts of three-high graphite. 25 parts of asphalt,

[0048] Among them, needle coke powder is obtained by crushing needle coke and passing through a 200-mesh sieve; high graphite is high-density, high-purity, high-strength graphite with a density of 1.85g / cm 3 , fixed carbon content ≥ 99.9%, flexural strength ≥ 25MPa, compressive strength ≥ 50MPa; the preparation method of modified asphalt is: crush 70 parts of asphalt through a 200-mesh sieve to obtain asphalt powder, and dissolve the asphalt powder in tetrahydrofuran solvent To obtain the tetrahydrofuran solution of asphalt, add 13 parts of nano-silica, 5 parts of chromium ox...

Embodiment 3

[0051] A graphite crucible for vacuum smelting in an intermediate frequency furnace, comprising the following components in parts by weight:

[0052] 8 parts of needle coke with a particle size of 4-6 mm, 9 parts of needle coke with a particle size of 2-4 mm, 23 parts of needle coke with a particle size of 0-2 mm, 30 parts of needle coke powder, and 10 parts of Sangao graphite. 20 parts of asphalt,

[0053] Among them, needle coke powder is obtained by crushing needle coke and passing through a 200-mesh sieve; Sangao graphite is high-density, high-purity, high-strength graphite with a density of 1.85g / cm 3 , fixed carbon content ≥ 99.9%, flexural strength ≥ 25MPa, compressive strength ≥ 50MPa; the preparation method of modified asphalt is: crush 70 parts of asphalt through a 200-mesh sieve to obtain asphalt powder, and dissolve the asphalt powder in tetrahydrofuran solvent To obtain the tetrahydrofuran solution of asphalt, add 13 parts of nano-silica, 5 parts of chromium oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com