Method for adjusting synaptic plasticity of metal oxide synaptic transistor

A technology of oxides and transistors, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of difficulty in controlling the accuracy of synapse weight adjustment, long device preparation time, and complicated preparation processes, etc., to achieve improved synapse Touch performance, low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

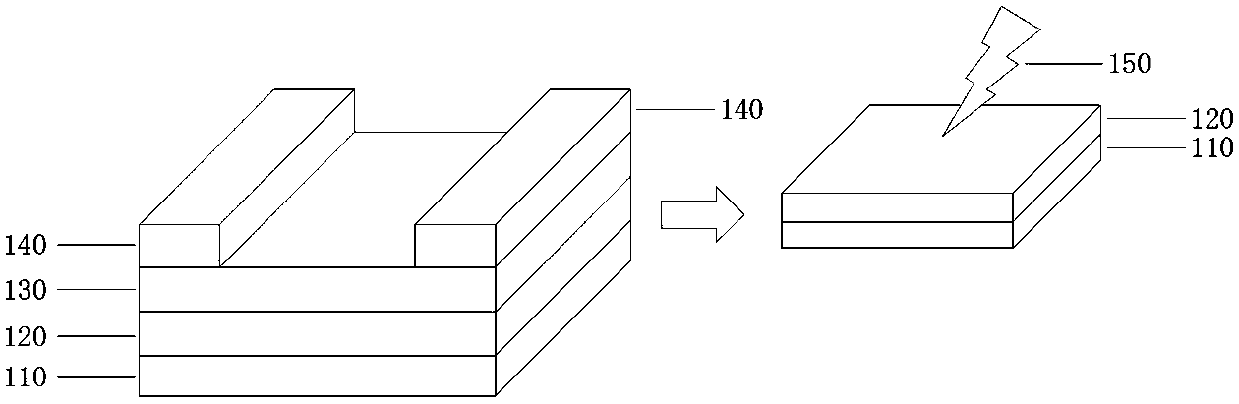

[0031] 1) A pure silicon wafer with a size of 1.5 cm×1.5 cm was ultrasonically cleaned with acetone, isopropanol, and deionized water, and then washed with deionized water and dried with nitrogen to obtain a clean silicon wafer as a substrate.

[0032] 2) Put Ta 2 o 5 Sputter on the silicon wafer in step 1) as an insulating layer, the sputtering power is 100 W, the pressure is 0.35 Pa, the rotation speed is 250 R, the argon-oxygen ratio is set to 30:2.5, the sputtering time is 14 minutes, and the thickness is about 120 nm.

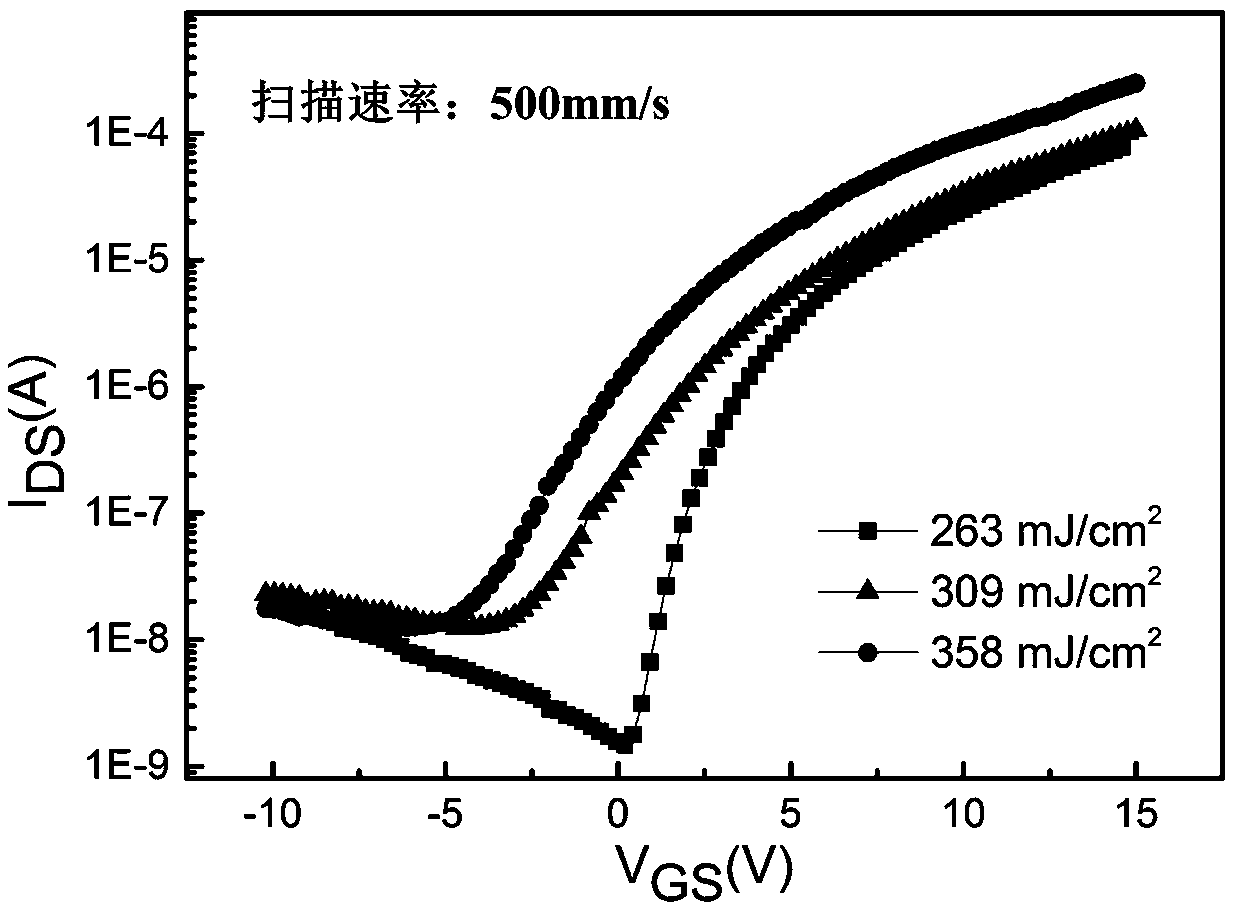

[0033] 3) The Ta obtained in step 2) 2 o 5 The thin film is processed by laser. The selected laser has a wavelength of 517 nm, a pulse output, a repetition frequency of 1 MHz, and a pulse width of 283 fs. The laser scanning method is set to grid scanning, the laser scanning rate is set to 500mm / s, and the laser power can be selected from 0 to 400 mJ / cm 2 between. The obtained transfer characteristic curve is as follows figure 2 shown.

[0034] 4) ...

Embodiment 2

[0037] 1) A pure silicon wafer with a size of 1.5 cm×1.5 cm was ultrasonically cleaned with acetone, isopropanol, and deionized water, and then washed with deionized water and dried with nitrogen to obtain a clean silicon wafer as a substrate.

[0038] 2) Put Ta 2 o 5 Sputter on the silicon wafer in step 1) as an insulating layer, the sputtering power is 100 W, the pressure is 0.35 Pa, the rotation speed is 250 R, the argon-oxygen ratio is set to 30:2.5, the sputtering time is 14 minutes, and the thickness is about 120 nm.

[0039] 3) The Ta obtained in step 2) 2 o 5 The thin film is processed by laser. The selected laser has a wavelength of 517 nm, a pulse output, a repetition frequency of 1 MHz, and a pulse width of 283 fs. The laser scanning method is set to grid scanning, and the laser power is set to 300 mJ / cm 2 , the laser scanning speed can be selected between 300~700 mm / s.

[0040] 4) Sputter the semiconductor layer indium tin oxide on the silicon wafer in step 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com