Application of modified M-SAPO-RHO zeolite molecular sieve used as ethylene selective adsorbent

A zeolite molecular sieve and selective adsorption technology, applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and base exchange compound, molecular sieve and base exchange phosphate, etc., can solve the problems of high preparation cost, poor stability, poor selectivity, etc., and achieve composition Good stability, efficient separation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the present invention, the preparation method of the modified M-SAPO-RHO type zeolite molecular sieve preferably comprises the following steps:

[0035] Mixing a silicon source, an aluminum source, phosphoric acid, a template, cetyltrimethylammonium bromide, SAPO-RHO seed crystals and water to obtain an initial reaction gel; the template is diethylamine;

[0036] Crystallizing the initial reaction gel to obtain a SAPO-RHO type zeolite molecular sieve, the SAPO-RHO type molecular sieve contains a template;

[0037] Under the condition of not removing the template agent, the SAPO-RHO type zeolite molecular sieve is directly mixed with the cationic solution, and roasted after ion exchange reaction to obtain the modified M-SAPO-RHO type zeolite molecular sieve; the cationic solution Cations include Li + and / or Na + ; The concentration of the cationic solution is 0.5-1.0 mol / L.

[0038] In the present invention, unless otherwise specified, all raw material components a...

Embodiment 1

[0067] Under the condition of stirring at room temperature, add 2.3g of phosphoric acid and 1.4g of pseudo-boehmite into 7mL of water and stir to mix evenly, add 0.9g of silica sol and 0.15g of cetyltrimethylammonium bromide and stir for 2h Mix until uniform, then slowly add 1.75g of diethylamine and stir for 3 hours to obtain an initial gel, then add 0.036g of SAPO-RHO seed crystals and stir for 15 minutes to obtain a final uniform initial reaction gel; transfer the gel to high pressure reaction In the kettle, crystallize at 200°C for 48h, then carry out suction filtration or centrifugal separation, and dry the obtained solid material at 100°C for 12h to obtain SAPO-RHO zeolite molecular sieve; the relative crystallinity of SAPO-RHO zeolite molecular sieve is 100%;

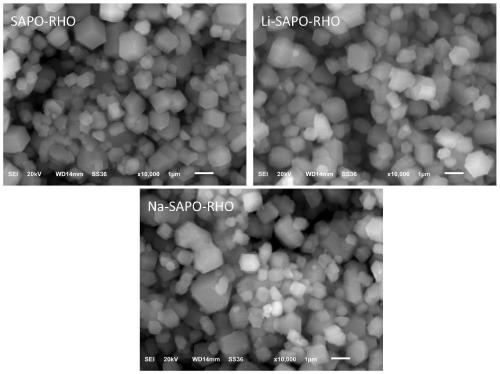

[0068] XRD pattern of SAPO-RHO type zeolite molecular sieve figure 1 shown by figure 1 It can be seen that the synthetic product of the present invention is a SAPO-RHO type zeolite molecular sieve with good c...

Embodiment 2

[0072]According to the ratio S / L=1:50 ratio of SAPO-RHO type zeolite molecular sieve quality and lithium chloride solution volume, the SAPO-RHO type zeolite molecular sieve prepared in Example 1 and 0.5mol / L lithium chloride solution were stirred at room temperature After mixing for 5 hours, filtering, washing the obtained solid material with deionized water, drying at 100°C for 12 hours, and then roasting in a muffle furnace at 600°C for 4 hours to obtain a modified Li-SAPO-RHO zeolite molecular sieve, wherein , Li / (Si+Al+P) molar ratio=0.07.

[0073] The modified Li-SAPO-RHO zeolite molecular sieve was activated under vacuum conditions at 350°C for 10 hours. After the sample was cooled to room temperature, a single-component gas isothermal adsorption-desorption test was performed. The test temperature was 298K and the test pressure was 1 bar, the separation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com