A kind of sic/zrc composite fiber and its preparation method and use

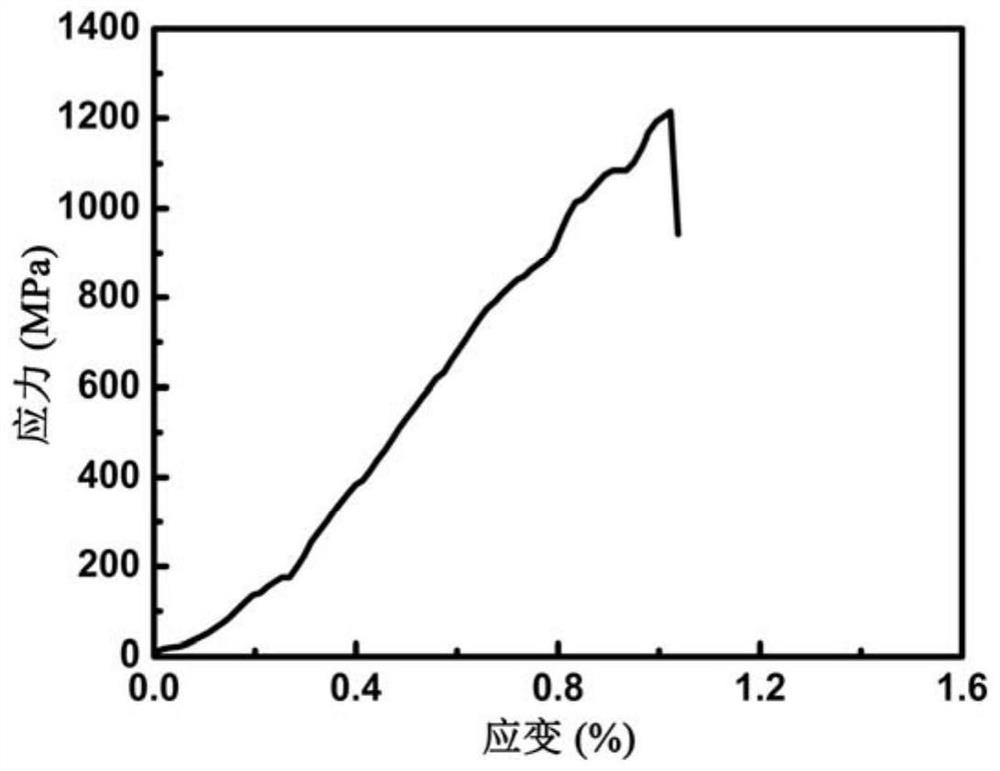

A composite fiber and polymer technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of complex preparation process, low fracture strength, harsh conditions, etc., and achieve short preparation process and excellent tensile strength Strong, easy-to-industrialize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

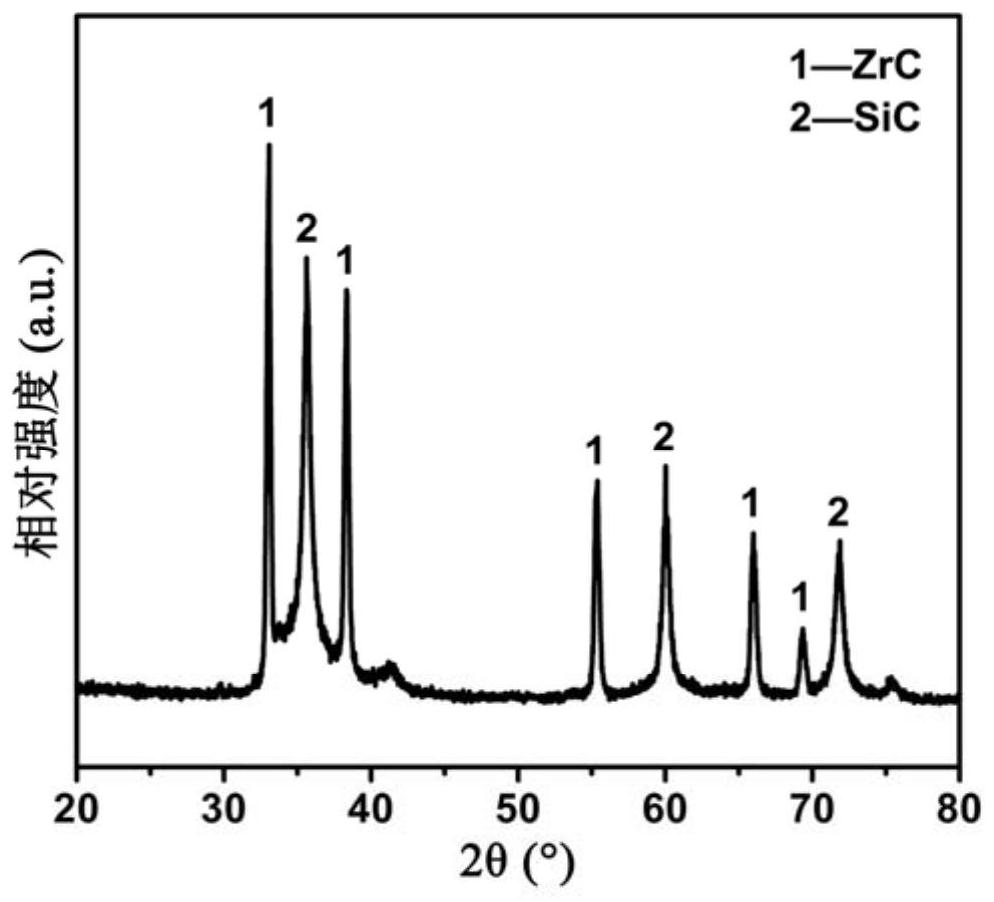

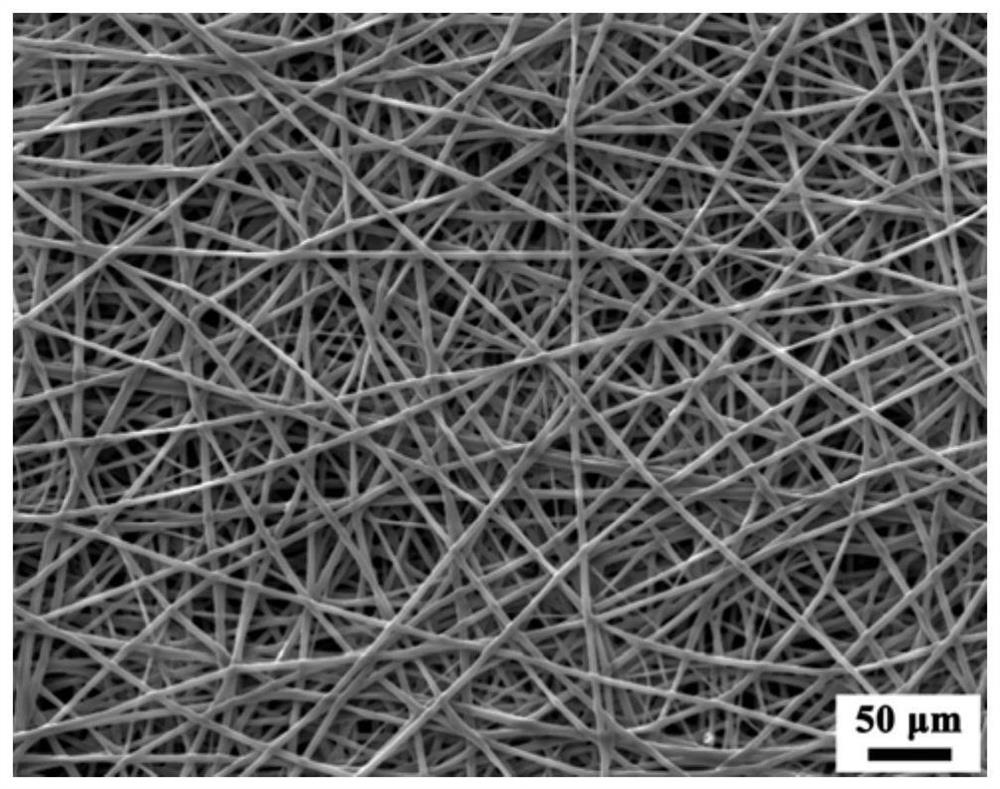

[0048] This embodiment provides a preparation method of SiC / ZrC composite fiber, and the method includes the following steps:

[0049] (1) At 18°C, a hybrid spinning solution of liquid polycarbosilane and polyzirconoxane was prepared in a mass ratio of 3:1, and fully magnetically stirred for 3 h to obtain a hybrid spinning solution with a viscosity of 4.8 Pa·s;

[0050] (2) After the hybrid spinning solution obtained in step (1) is loaded into a glass syringe, electrospinning is performed under the conditions of an output voltage of 15kV, an injection flow rate of 2.5mL / h, and a flat aluminum foil take-up distance of 10cm, and spinning for 6 hours. Then, the SiC / ZrC composite fiber precursor was obtained;

[0051] (3) The SiC / ZrC composite fiber precursor obtained in step (2) was heated to 120°C for 3 h at a rate of 2°C / min under an argon atmosphere, and finally, under the protection of argon, the temperature was 5°C / min. The temperature was increased to 1600°C for 2 hours, a...

Embodiment 2

[0057] This embodiment provides a preparation method of SiC / ZrC composite fiber, and the method includes the following steps:

[0058] (1) At 20°C, a hybrid spinning solution of liquid polycarbosilane and zirconium acetylacetonate was prepared in a mass ratio of 3.5:1, and fully magnetically stirred for 4 h to obtain a hybrid spinning solution with a viscosity of 3.4 Pa·s;

[0059] (2) After loading the hybrid spinning solution obtained in step (1) into a glass syringe, electrospinning was performed under the conditions of an output voltage of 15kV, an injection flow rate of 2mL / h, and a flat aluminum foil collection distance of 15cm. After spinning for 5h , to obtain SiC / ZrC composite fiber precursor;

[0060] (3) The SiC / ZrC composite fiber precursor obtained in step (2) was heated to 140°C for 2 h at a rate of 2°C / min under an argon atmosphere, and finally, under the protection of argon, the temperature was 5°C / min. The temperature was increased to 1550°C for 2 hours, and ...

Embodiment 3

[0063] This embodiment provides a preparation method of SiC / ZrC composite fiber, and the method includes the following steps:

[0064] (1) At 22 °C, a hybrid spinning solution of liquid polycarbosilane and polyziroxane was prepared in a mass ratio of 4:1, and fully magnetically stirred for 2 h to obtain a hybrid spinning solution with a viscosity of 2.1 Pa·s;

[0065] (2) After the hybrid spinning solution obtained in step (1) is loaded into a glass syringe, electrospinning is performed under the conditions of an output voltage of 15kV, an injection flow rate of 1.5mL / h, and a flat aluminum foil receiving distance of 10cm, and spinning for 5h. Then, the SiC / ZrC composite fiber precursor was obtained;

[0066] (3) The SiC / ZrC composite fiber precursor obtained in step (2) was heated to 120°C for 3 hours at a rate of 5°C / min under an argon atmosphere, and finally, under the protection of argon, the temperature was 8°C / min. The temperature was increased to 1500°C for 3 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com