sw-cnts fiber reinforced magnesium alloy matrix composite material and method

A fiber-reinforced and composite material technology, applied in the field of preparation of the SW-CNTs fiber-reinforced magnesium alloy-based composite material, can solve the problem that cannot be used to prepare single-walled carbon nanotube magnesium alloy-based composite materials and ultra-fine diameter wires materials and other issues, to achieve the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

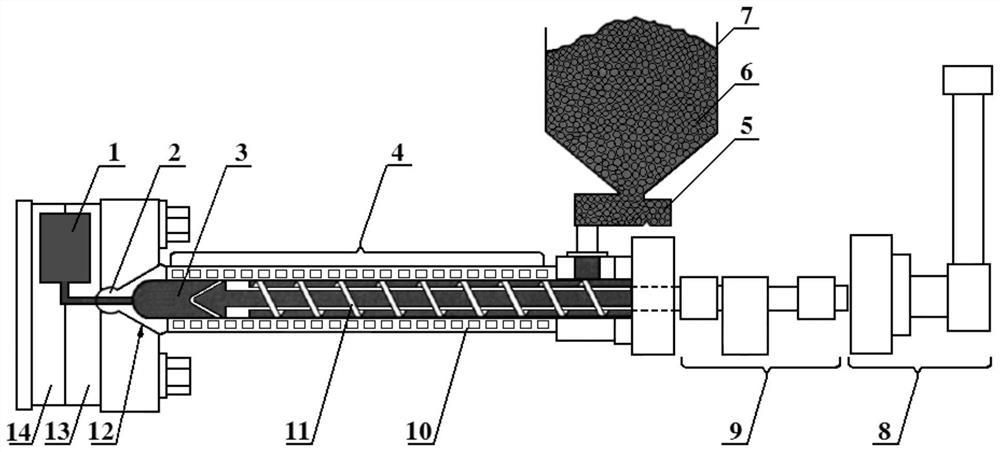

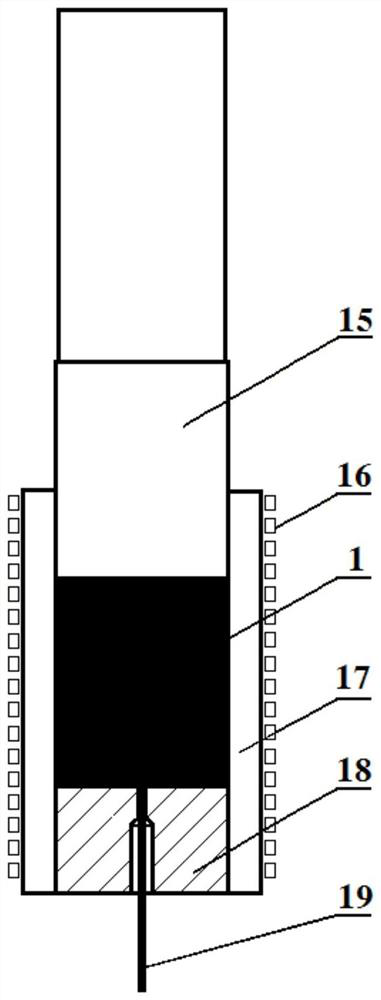

Method used

Image

Examples

Embodiment 1

[0051] Select 450 mesh AZ91 magnesium alloy powder as the matrix of the composite material, SW-CNTs are fibers with a length of 2 μm, weighed according to the weight percentage ratio, the fiber content of SW-CNTs is 0.5%, and the rest is AZ91 magnesium alloy powder, the above components The sum of weight percentages is 100%. Use Φ5mm grinding balls and capsule grinding balls, the number of grinding balls and capsule grinding balls is the same, and the weight of the grinding balls is 60% of the total weight of the SW-CNTs fibers and AZ91 magnesium alloy powder to be ball-milled.

[0052] The above-mentioned powders and balls were put into a ball mill tank together, and the mixed powder was ball milled for 48 hours in a horizontal high-energy ball mill at 150 rpm under the protection of argon. Mixed uniformly by ball milling machine, and dispersed SW-CNTs fibers, avoiding entanglement and agglomeration into bundles. Due to the use of argon protection, the burning of SW-CNTs fib...

Embodiment 2

[0057] Choose 500 mesh ZK60 magnesium alloy powder as the matrix of the composite material, SW-CNTs are fibers with a length of 3 μm, weighed according to weight percentage, SW-CNTs fiber content is 1%, and the rest is ZK60 magnesium alloy powder, the weight of each component above The sum of the percentages is 100%. Use Φ5mm grinding balls and capsule grinding balls, the number of grinding balls and capsule grinding balls is the same, and the weight of the grinding balls is 60% of the total weight of the SW-CNTs fibers and ZK60 magnesium alloy powder to be ball-milled.

[0058] The above-mentioned powders and balls were put into a ball mill tank together, and the mixed powder was ball milled for 48 hours in a horizontal high-energy ball mill at 150 rpm under the protection of argon. Mixed uniformly by ball milling machine, and dispersed SW-CNTs fibers, avoiding entanglement and agglomeration into bundles. Due to the use of argon protection, the burning of SW-CNTs fibers is a...

Embodiment 3

[0063] Select 600-mesh Mg-6.5Zn-2.6Y-0.8Ce-1.2Nd alloy powder as the matrix of composite materials, SW-CNTs are fibers with a length of 5 μm, weighed according to weight percentage, SW-CNTs fiber content is 1.5%, and the rest It is Mg-6.5Zn-2.6Y-0.8Ce-1.2Nd alloy powder, and the sum of the weight percentages of the above components is 100%. Use Φ5mm grinding balls and capsule grinding balls, the number of grinding balls and capsule grinding balls is the same, and the weight of the grinding balls is the total weight of SW-CNTs fibers and Mg-6.5Zn-2.6Y-0.8Ce-1.2Nd powder to be ball-milled 60% of.

[0064] The above-mentioned powders and balls were put into a ball mill tank together, and the mixed powder was ball milled for 48 hours in a horizontal high-energy ball mill at 150 rpm under the protection of argon. Mixed uniformly by ball milling machine, and dispersed SW-CNTs fibers, avoiding entanglement and agglomeration into bundles. Due to the use of argon protection, the burn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com