Efficient denitrification treatment method for landfill leachate

A technology of landfill leachate and treatment method, which is applied in the field of high-efficiency denitrification treatment of landfill leachate, which can solve problems such as increased operating costs, prolonging the process, and increasing operational difficulty, and achieves strong applicability, improved processing efficiency, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

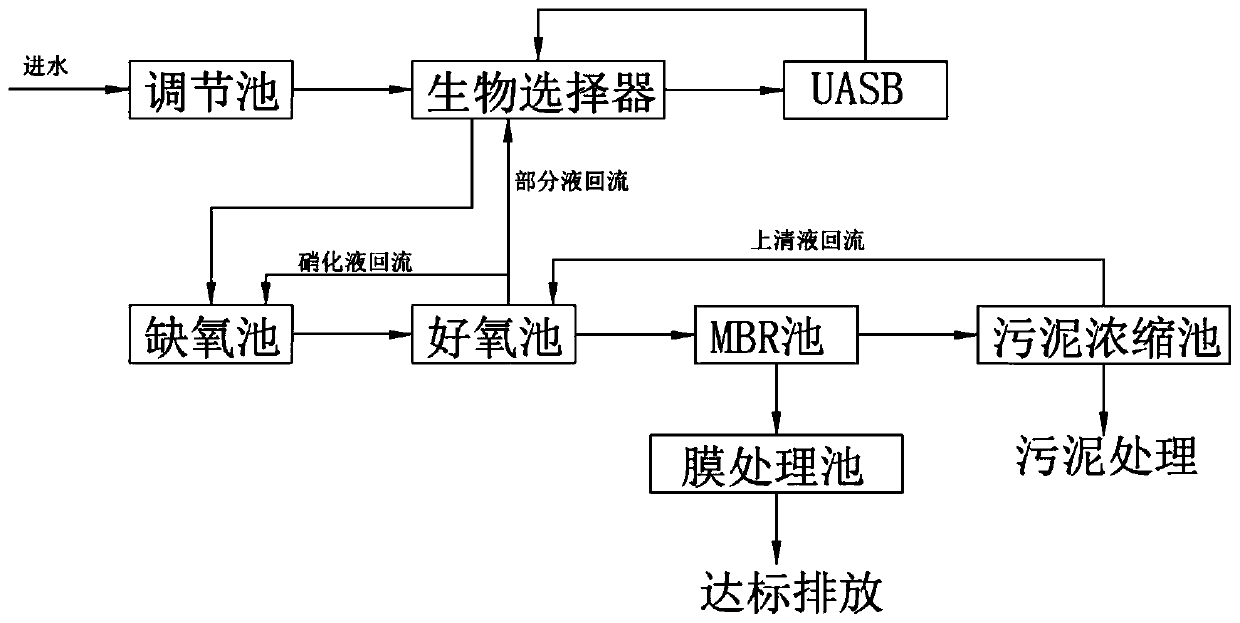

Image

Examples

Embodiment 1

[0034] Preparation of activated fiber web

[0035] The preparation of porous iridium particles: get the metal iridium powder with a particle size of 10 μm, press it into a prefabricated porous metal plate with a cold isostatic press, the thickness of the metal plate is 0.2mm, place the metal plate in a sintering furnace, feed nitrogen, After the air was exhausted, it was calcined at 1500°C for 4 hours in a nitrogen atmosphere, cooled to room temperature, and then ground to obtain porous iridium particles.

[0036] Preparation of iridium composite particles: weigh 10g FeCl 2 4H 2 O and 20g FeCl 3 ·6H 2O was dissolved in 1000ml of deionized water, then 40g of porous iridium particles were added, ultrasonically dispersed for 10min at a frequency of 25kHz and a power of 145W, heated in an oil bath to 60°C, and reacted for 15min. React at a high temperature for 5 hours in a high-pressure reactor. After the reaction, cool to room temperature, stir at a speed of 200r / min for 30 m...

Embodiment 2

[0047] Preparation of activated fiber web

[0048] The preparation of porous iridium particles: get the metal iridium powder with a particle size of 30 μm, press it into a prefabricated porous metal plate with a cold isostatic press, the thickness of the metal plate is 0.2mm, place the metal plate in a sintering furnace, feed nitrogen, After the air was exhausted, it was calcined at 1600°C for 3 hours in a nitrogen atmosphere, cooled to room temperature, and then ground to obtain porous iridium particles.

[0049] Preparation of iridium composite particles: weigh 10g FeCl 2 4H 2 O and 20g FeCl 3 ·6H 2 O was dissolved in 1000ml of deionized water, then 40g of porous iridium particles were added, ultrasonically dispersed for 10min at a frequency of 25kHz and a power of 145W, heated in an oil bath to 80°C, and reacted for 10min. React at a high temperature for 3 hours in a high-pressure reactor. After the reaction, cool to room temperature, stir at a speed of 300r / min for 30 ...

Embodiment 3

[0054] Preparation of activated fiber web

[0055] Preparation of porous iridium particles: get the metal iridium powder with a particle size of 20 μm, press it into a prefabricated porous metal plate with a cold isostatic press, the thickness of the metal plate is 0.2mm, place the metal plate in a sintering furnace, and feed nitrogen, After exhausting the air, calcining at 1550° C. for 3.5 hours under nitrogen atmosphere, cooling to room temperature, and grinding to obtain porous iridium particles.

[0056] Preparation of iridium composite particles: weigh 10g FeCl 2 4H 2 O and 20g FeCl 3 ·6H 2 O was dissolved in 1000ml of deionized water, then 40g of porous iridium particles were added, ultrasonically dispersed for 10min at a frequency of 25kHz and a power of 145W, heated in an oil bath to 70°C, and reacted for 30min. React at a high temperature for 4 hours in a high-pressure reactor. After the reaction, cool to room temperature, stir at a speed of 250r / min for 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesh diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com