Method for preparing epitaxial graphene through laser heating

A technology of laser heating and graphene, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of etching speed, etching quality, difficult control of etching hydrogen concentration, pressure, and time, etc. Achieve the effect of improving crystal quality and shortening the growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

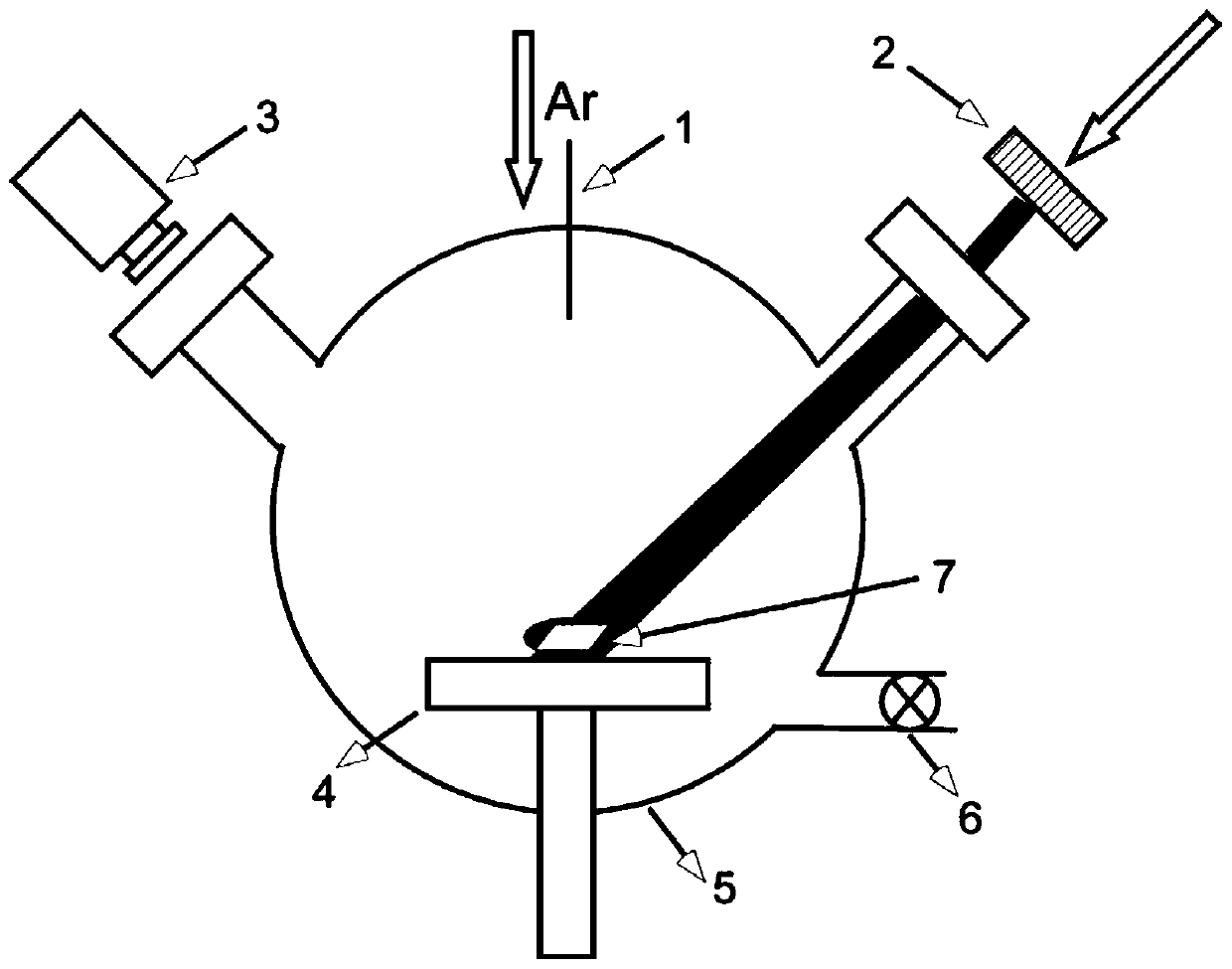

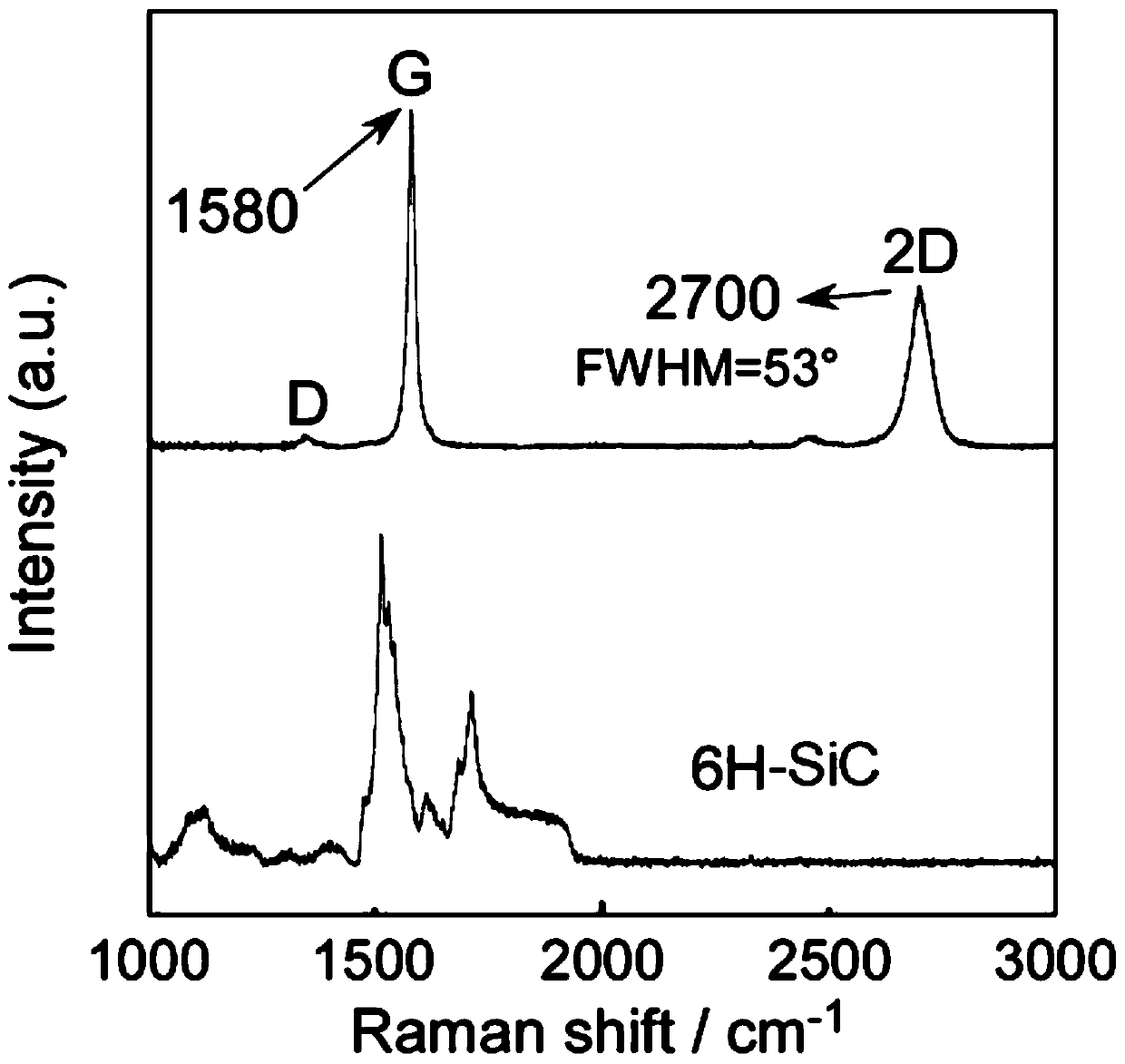

[0027] Laser heating to prepare epitaxial graphene, the schematic diagram of the device is shown in figure 1 As shown, the specific steps are as follows:

[0028] 1) Select single crystal 6H-SiC (0001) as the growth substrate, clean it and put it on the stage 7 in the cavity 5 of the laser chemical vapor deposition equipment. The stage 7 is located on the heating furnace 4 and passes through the Ar gas pipeline 1 Introduce high-purity Ar gas into the cavity (flow rate is 500 sccm, purity 99.999%), and then adjust the pressure so that the pressure in the cavity is 10000 Pa (error ± 5%);

[0029] 2) Turn on the laser device 2 (power 1kW), and use the infrared thermometer 3 to test the temperature of the substrate. The laser wavelength is 1000nm, and the temperature of the substrate surface is raised to 1900°C at a heating rate of 400°C / s (the laser power density is 550W cm -2 ), laser irradiation at 1900°C for 1 min;

[0030] 3) Adjust the laser power and keep the wavelength c...

Embodiment 2

[0035] Epitaxial graphene was prepared at different laser heating temperatures, and the specific steps were as follows:

[0036] 1) Select single crystal 4H-SiC (0001) as the growth substrate, clean it and put it into the cavity of laser chemical vapor deposition equipment, and pass high-purity Ar gas into the cavity (flow rate is 500 sccm, purity is 99.999%), Then adjust the pressure so that the pressure in the cavity is 10000Pa (error ± 5%);

[0037] 2) Turn on the laser (power 1kW), use an infrared thermometer to measure the temperature of the substrate, set the laser wavelength to 1064nm, and raise the temperature of the substrate surface to 1550°C, 1620°C, 1700°C and 1780°C at a heating rate of 500°C / s ( The laser power density is 448~538W·cm -2 ), continue laser irradiation for 5 minutes;

[0038] 3) Adjust the laser power and keep the wavelength constant, so that the surface of the substrate is cooled to 600°C at a cooling rate of 200°C / s, then turn off the laser, sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com