MAX phase coating for resisting molten CMAS corrosion of thermal barrier coating and thermal spraying preparation method

A thermal barrier coating, anti-melting technology, applied in the direction of fusion spraying, coating, metal material coating process, etc., can solve problems such as corrosion damage of thermal barrier coating, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

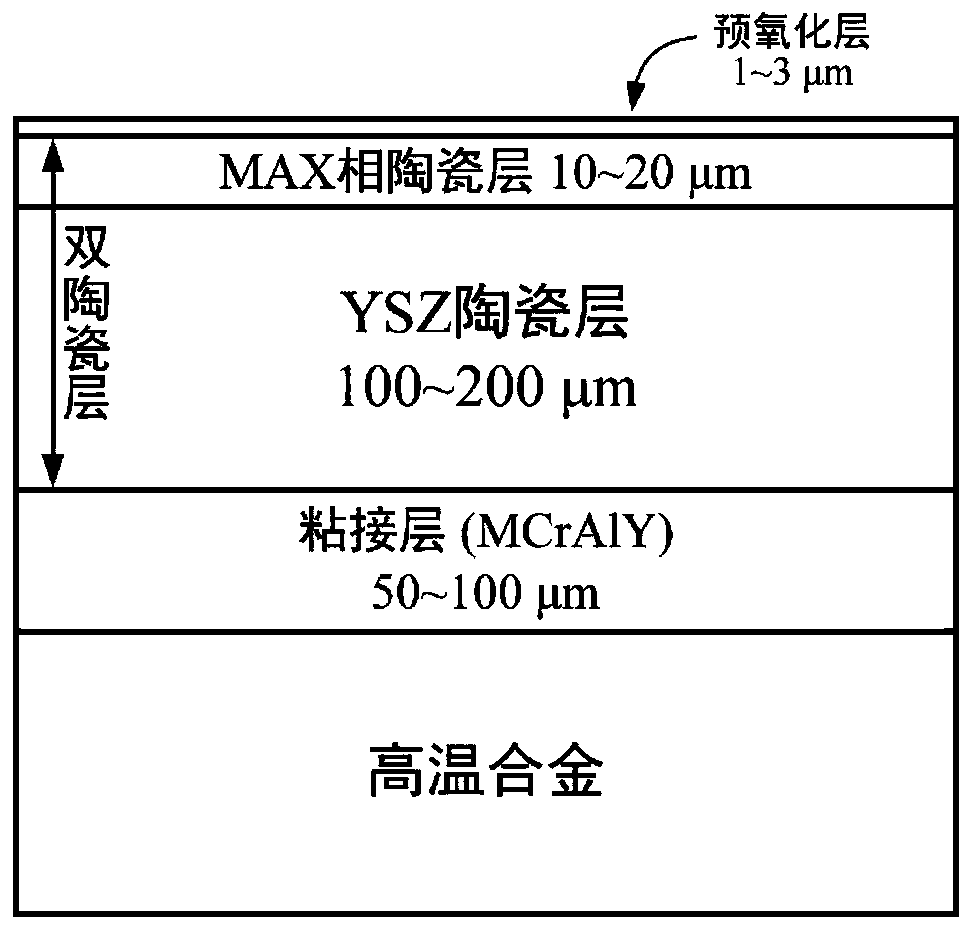

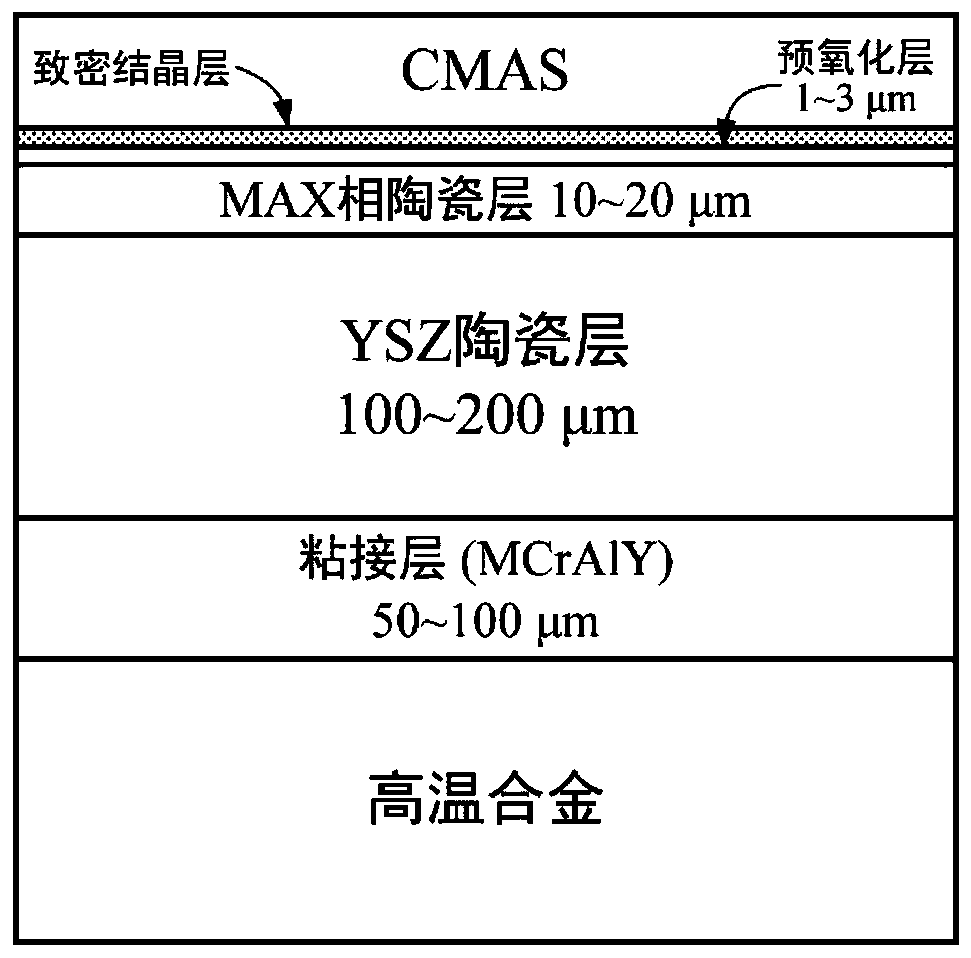

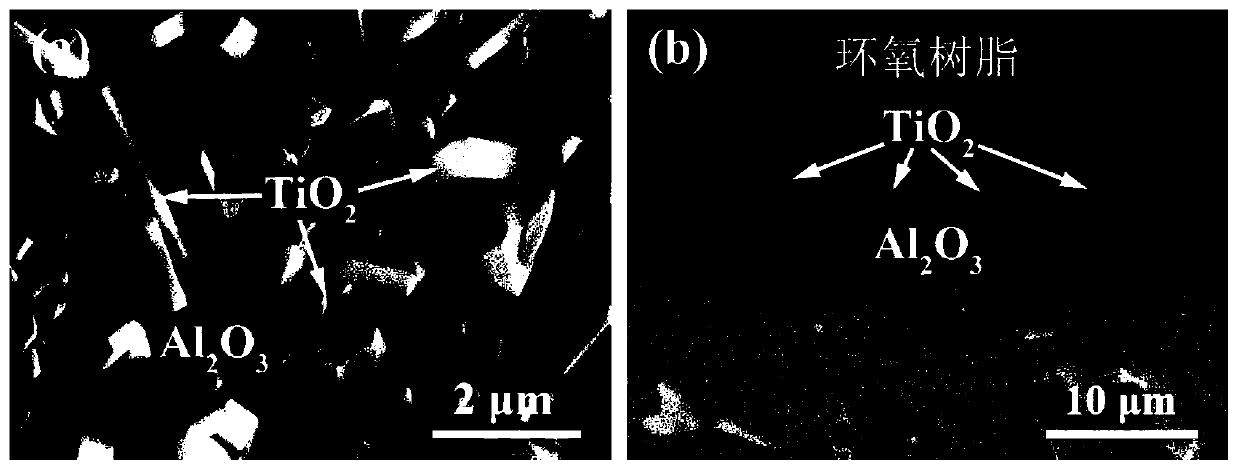

[0040] Example 1: Preparation of a thermal barrier coating resistant to molten CMAS corrosion. The coating consists of a high-temperature alloy substrate, a NiCrAlY bonding layer, a YSZ ceramic layer, and Ti 2 AlC ceramic layer and its pre-oxidized layer composition, of which Ti 2 The AlC coating is prepared by supersonic flame spraying method, including the following steps:

[0041] In the first step, YSZ ceramic coating is prepared on the superalloy substrate with NiCrAlY bonding layer.

[0042] The YSZ ceramic layer is prepared on the surface of the NiCrAlY bonding layer by atmospheric plasma spraying. The main process parameters are as follows: spraying voltage 60V, current 600A, main gas Ar flow rate 40slpm, H 2 The flow rate is 10slpm, the powder feeding rate is 15g / min, the spraying distance is 100mm, and the thickness of the YSZ ceramic layer obtained is 150μm.

[0043] The second step is to prepare Ti for supersonic flame spraying 2 AlC powder.

[0044] For supply Ti 2 The Al...

Embodiment 2

[0053] Example 2: Preparation of a thermal barrier coating resistant to molten CMAS corrosion. The coating consists of a high-temperature alloy substrate, a NiCrAlY bonding layer, a YSZ ceramic layer, and Ti 2 AlC ceramic layer and its pre-oxidized layer composition, of which Ti 2 The AlC coating is prepared by supersonic flame spraying method, including the following steps:

[0054] In the first step, YSZ ceramic coating is prepared on the superalloy substrate with NiCrAlY bonding layer.

[0055] The YSZ ceramic layer is prepared on the surface of the NiCrAlY bonding layer by atmospheric plasma spraying. The main process parameters are as follows: spraying voltage 60V, current 600A, main gas Ar flow rate 40slpm, H 2 The flow rate is 10slpm, the powder feeding rate is 15g / min, the spraying distance is 100mm, and the thickness of the YSZ ceramic layer obtained is 150μm.

[0056] The second step is to prepare Ti for supersonic flame spraying 2 AlC powder.

[0057] For supply Ti 2 The Al...

Embodiment 3

[0064] Example 3: Preparation of a thermal barrier coating resistant to molten CMAS corrosion. The coating consists of a high-temperature alloy matrix, a NiCrAlY bonding layer, a YSZ ceramic layer, and Ti 3 AlC 2 Ceramic layer and its pre-oxidized layer composition, of which Ti 3 AlC 2 The coating is prepared by supersonic flame spraying method, including the following steps:

[0065] In the first step, YSZ ceramic coating is prepared on the superalloy substrate with NiCrAlY bonding layer.

[0066] The YSZ ceramic layer is prepared on the surface of the NiCrAlY bonding layer by atmospheric plasma spraying. The main process parameters are as follows: spraying voltage 60V, current 600A, main gas Ar flow rate 40slpm, H 2 The flow rate is 10slpm, the powder feeding rate is 15g / min, the spraying distance is 100mm, and the thickness of the YSZ ceramic layer obtained is 150μm.

[0067] The second step is to prepare Ti for supersonic flame spraying 3 AlC 2 powder.

[0068] For supply Ti 3 AlC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com