Preparation method and application of strontium-doped hydroxyapatite heavy metal adsorption material

A strontium hydroxyapatite and adsorption material technology, which is applied in the field of preparation of strontium-doped hydroxyapatite heavy metal adsorption materials, can solve the problems of complex artificial synthesis, complex preparation process, and slow adsorption rate, and achieve good controllability of the reaction , Simple preparation process and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] (1) Preparation of precursor solution: prepare 0.2mol / L calcium nitrate (Ca(NO 3 ) 2 4H 2 O), 0.2mol / L diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) and 0.2mol / L strontium nitrate (Sr(NO 3 ) 2 ); Take 250mL each of the prepared calcium nitrate and strontium nitrate solutions and mix evenly.

[0019] (2) Add 300mL of the prepared diammonium hydrogen phosphate solution, and quickly add ammonia water to adjust the pH to 10.5. During this process, the mixed solution should be stirred rapidly.

[0020] (3) After magnetically stirring the obtained milky white suspension for 30 minutes, it was aged in a water bath at 50°C for 24 hours.

[0021] (4) Centrifuge and wash the white precipitate after aging three times with ethanol and water, dry it in an oven at 80°C for 24 hours, and grind the obtained white solid through a 100-mesh sieve to obtain strontium-doped hydroxyapatite heavy metal Adsorbent material.

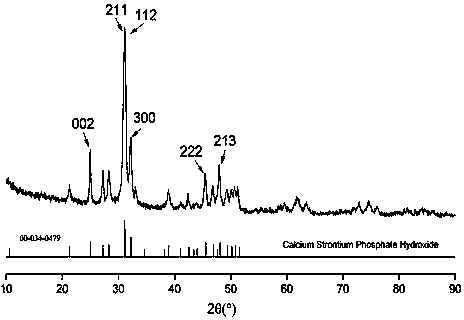

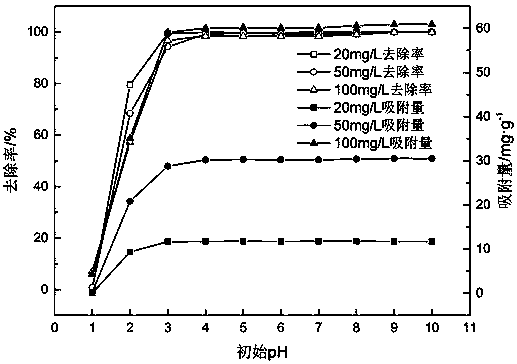

[0022] The strontium-doped hydroxyapatite heavy metal ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com