Completely degradable tissue engineering skin scaffold material and preparation method thereof

A technology for tissue engineering skin and scaffold materials, which is applied in non-woven fabrics, pharmaceutical formulations, textiles, and papermaking. It can solve problems such as refractory degradation, unfavorable cell adhesion and migration, and easy shrinkage and deformation, so as to improve the elastic modulus and Effects of compressive stress, good cell adhesion and proliferation, enhanced stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

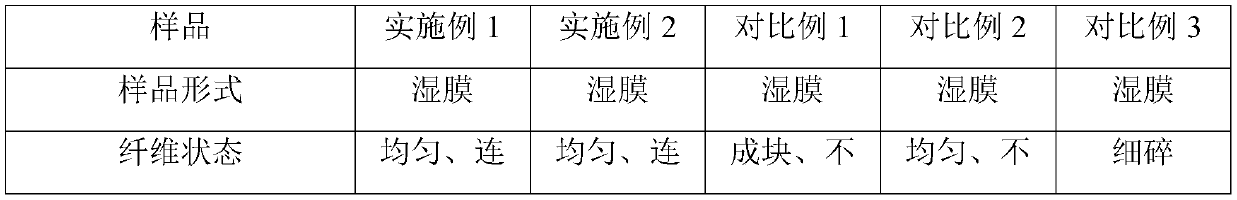

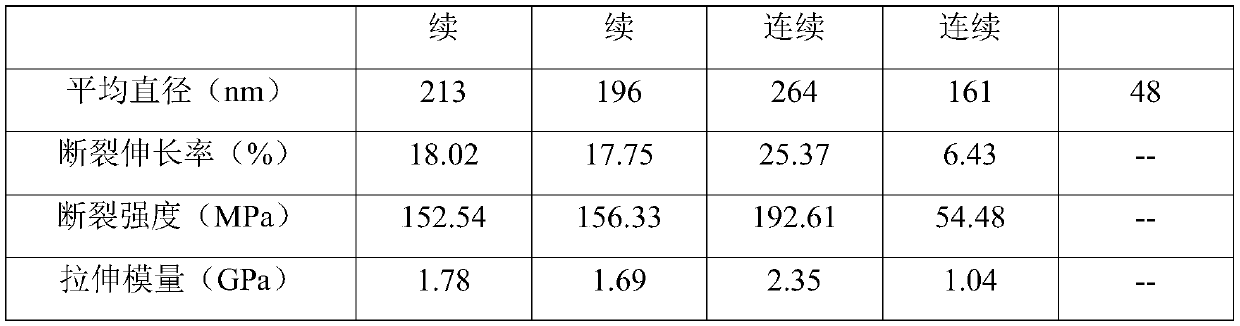

Examples

Embodiment 1

[0027] Preparation of bacterial cellulose / chitosan fiber layer: Add dissolved chitosan to the culture medium of Gluconoacetobacter xylinum to synthesize bacterial cellulose / chitosan composite gel in situ, and the composite gel was treated with 0.5mol / After purification by alkali hydrolysis at room temperature for 8 hours with L NaOH solution, the cellulase was immobilized on the surface of the bacterial cellulose / chitosan fiber by freeze-drying method to obtain the bacterial cellulose / chitosan nanofiber layer.

Embodiment 2

[0029] Except that the composite gel was purified by alkaline hydrolysis for 10 h during the preparation of the bacterial cellulose / chitosan fiber layer, the others were the same as in Example 1.

Embodiment 3

[0031] The preparation method of polylactic acid / hyaluronic acid / silk fibroin micro-nano fiber comprises the following steps: (1) preparation of silk film: the volume ratio of calcium chloride, water and ethanol dissolved in 80° C. after mulberry silk degumming is 1: In the mixed solution of 8:2, stir and dissolve, obtain pure silk fibroin solution after dialysis, and cast it into a film for later use; (2) Preparation of spinning solution 1: mix silk fibroin film with hyaluronic acid with a relative molecular mass of 1.5 million Add the powder together in the formic acid solution to obtain spinning solution 1; (3) Preparation of spinning solution 2: polylactic acid is dissolved in a mixed solvent with a volume ratio of chloroform and acetone of 2:1, and is prepared into a 5wt% polylactic acid solution at room temperature Stir evenly to obtain spinning solution 2; (4) Coaxial electrospinning: take spinning solution 1 and spinning solution 2 and put them in 10mL syringes respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com