High-concentrated non-phosphorus transforming agent

A transforming agent, high concentration technology, applied in the direction of metal material coating process, can solve the problems of inconvenient transportation, storage, poor coating adhesion, endangering human health, etc., to reduce pollution and harm to human body, improve The effect of quality stability and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

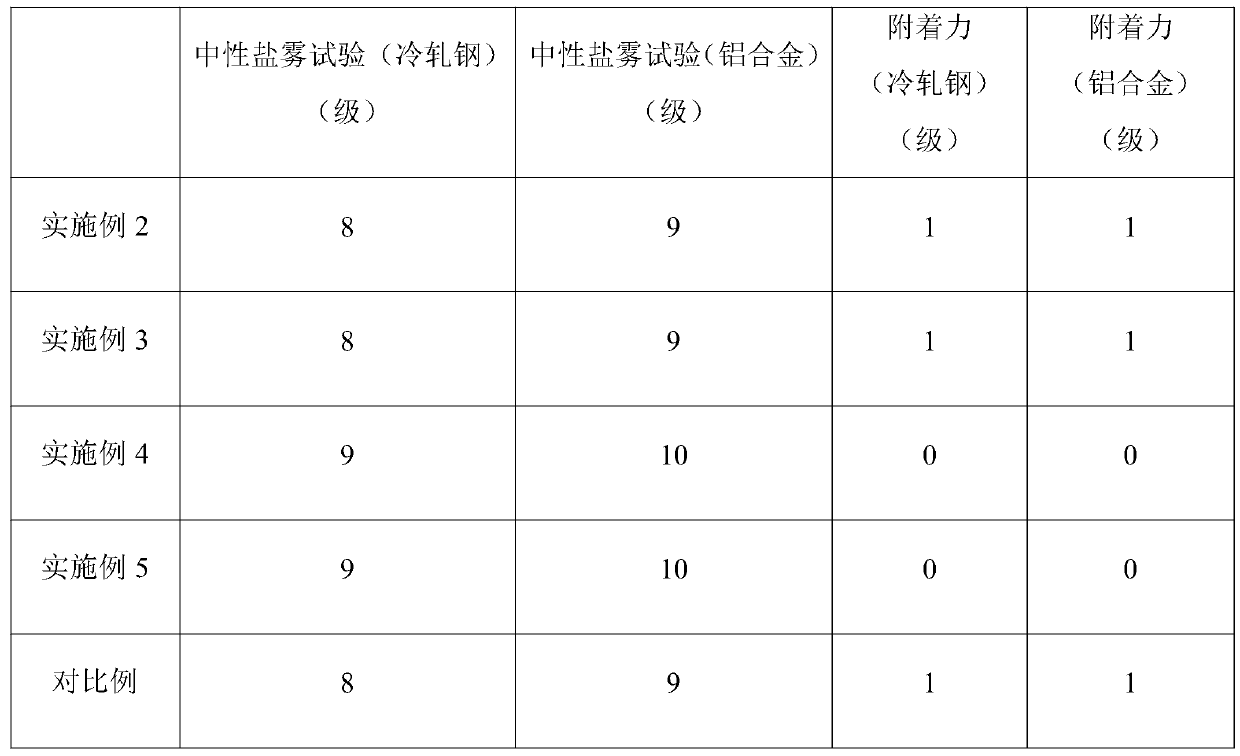

Examples

Embodiment 1

[0054] A highly concentrated phosphorus-free conversion agent, characterized in that it is made of raw materials comprising the following parts by weight:

[0055] 30-50 parts of ammonium fluorozirconate,

[0056] 20-30 parts of fluozirconic acid,

[0057] 13-18 parts of fluotitanic acid,

[0058] 30-50 parts of aluminum nitrate,

[0059] 20-30 parts of deionized water.

[0060] Preferably, the highly concentrated phosphorus-free conversion agent is made of raw materials including the following parts by weight:

[0061] 35~46 parts of ammonium fluorozirconate,

[0062] 22-29 parts of fluorozirconic acid,

[0063] 14-17 parts of fluotitanic acid,

[0064] 31~38 parts of aluminum nitrate,

[0065] 23 to 26 parts of deionized water.

[0066] Preferably, the highly concentrated phosphorus-free conversion agent is made of raw materials including the following parts by weight:

[0067] 40 parts of ammonium fluorozirconate,

[0068] 26 parts of fluozirconic acid,

[0069] 15.5 parts of fluotitanic acid,...

Embodiment 2

[0085] A highly concentrated phosphorus-free conversion agent, characterized in that it is made of raw materials comprising the following parts by weight:

[0086] 35 parts of ammonium fluorozirconate,

[0087] 22 parts of fluorozirconic acid,

[0088] 13 parts of fluorotitanic acid,

[0089] 31 parts of aluminum nitrate,

[0090] 23 parts of deionized water.

[0091] Preferably, the method for using the highly concentrated phosphorus-free conversion agent includes the following steps:

[0092] A. Cleaning with non-phosphorus degreasing agent;

[0093] B water washing;

[0094] C. Phosphorus-free conversion agent treatment: temperature 25℃, pH 4.5, soaking or spraying treatment time 6min;

[0095] D. Wash with water;

[0096] E. Drying: the temperature is 87°C, the treatment time is 4min, and then the temperature is increased to 130°C, the treatment time is 7min.

Embodiment 3

[0098] A highly concentrated phosphorus-free conversion agent, characterized in that it is made of raw materials comprising the following parts by weight:

[0099] 46 parts of ammonium fluorozirconate,

[0100] 29 parts of fluorozirconate,

[0101] 18 parts of fluorotitanic acid,

[0102] 38 parts of aluminum nitrate,

[0103] 26 parts of deionized water.

[0104] Preferably, the method for using the highly concentrated phosphorus-free conversion agent includes the following steps:

[0105] A. Cleaning with non-phosphorus degreasing agent;

[0106] B water washing;

[0107] C. Phosphorus-free conversion agent treatment: temperature 25℃, pH 4.5, soaking or spraying treatment time 6min; D, water washing;

[0108] E. Drying: the temperature is 87°C, the treatment time is 4min, and then the temperature is increased to 130°C, the treatment time is 7min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com