Efficient halogen-free flame-retardant epoxy adhesive and preparation method thereof

A technology of epoxy adhesive and flame retardant, which is used in adhesives, epoxy resin glue, polymer adhesive additives, etc., can solve the problem of easy fire, low oxygen index of epoxy resin, easy dripping of epoxy resin, etc. problem, to achieve the effect of reducing flammability, excellent bonding performance and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

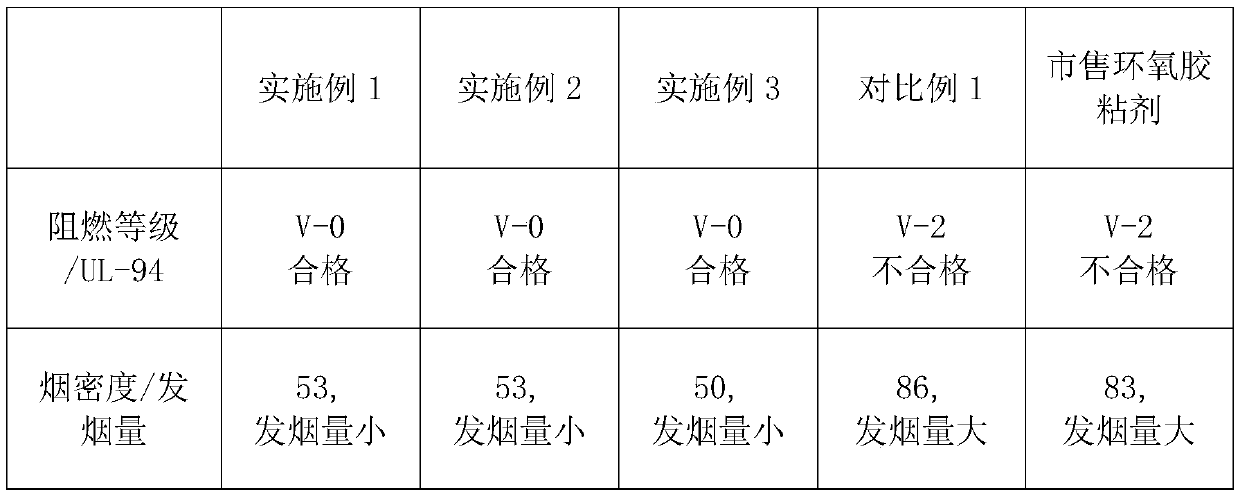

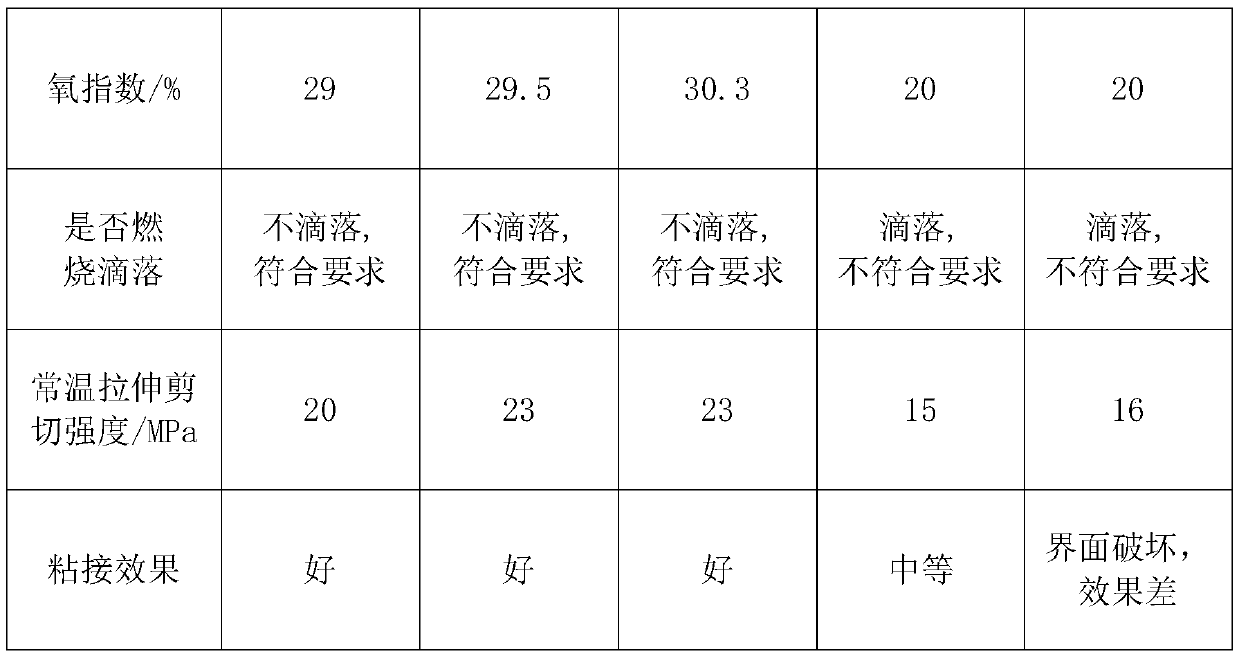

Embodiment 1

[0048] A component raw materials: bisphenol A epoxy resin (E-51) 45kg, dimer acid modified epoxy resin 10kg, melamine cyanurate (MCA) 25kg, antimony trioxide (Sb 2 o 3 ) 5kg, hyperbranched macromolecular carbon forming agent 3kg, polytetrafluoroethylene 0.5kg, 1,4-butanediol diglycidyl ether (622) 5kg, fumed silica 0.3kg, aluminum hydroxide 30kg, γ-shrink Glyceryl ether oxypropyl trimethoxysilane (KH-560) 1.0kg, the above-mentioned raw materials are added into the reaction kettle in order, and stirred and dispersed until the materials are uniform and have no color difference.

[0049] B component raw materials: modified amine curing agent 50kg, fumed silica 0.6kg, aluminum hydroxide 30kg, γ-aminopropyltriethoxysilane (KH-550) 0.6kg, the above-mentioned raw materials are added to the reaction kettle in order , Stir and disperse until the material is uniform and without color difference.

Embodiment 2

[0051] A component raw materials: bisphenol A epoxy resin (E-51) 25kg, bisphenol A epoxy resin (E-44) 10kg, polyurethane modified epoxy resin 10kg, ammonium polyphosphate (APP) 20kg, trioxide Antimony (Sb 2 o 3 ) 4kg, hyperbranched macromolecular carbon forming agent 3kg, polytetrafluoroethylene 0.5kg, 1,6-hexanediol diglycidyl ether 5kg, fumed silica 0.3kg, aluminum hydroxide 25kg, montmorillonite 5kg, γ - 0.9 kg of glycidyl etheroxypropyltrimethoxysilane (KH-560), the above-mentioned raw materials are added into the reaction kettle in sequence, and stirred and dispersed until the materials are uniform and have no color difference.

[0052] B component raw materials: modified amine curing agent 45kg, fumed silica 0.6kg, aluminum hydroxide 25kg, montmorillonite 5kg, γ-aminopropyltriethoxysilane (KH-550) 0.6kg, the above raw materials are as follows Sequentially add to the reaction kettle, stir and disperse until the material is uniform and there is no color difference.

Embodiment 3

[0054]A component raw materials: bisphenol A epoxy resin (E-51) 40kg, bisphenol A epoxy resin (E-44) 10kg, carboxyl-terminated nitrile rubber and epoxy resin prepolymer 10kg, melamine cyanurate ( MCA) 25kg, zinc borate 5kg, hyperbranched macromolecular carbon forming agent 3kg, polytetrafluoroethylene 0.5kg, 1,4-butanediol diglycidyl ether 5kg, fumed silica 0.3kg, aluminum hydroxide 20kg, hydrogen Magnesium oxide 15kg, γ-glycidyl etheroxypropyl trimethoxysilane (KH-560) 0.8kg, the above raw materials were added to the reaction kettle in sequence, stirred and dispersed until the materials were uniform and without color difference.

[0055] B component raw materials: modified amine curing agent 50kg, fumed silica 0.6kg, aluminum hydroxide 20kg, magnesium hydroxide 15kg, γ-aminopropyl triethoxysilane (KH-550) 0.6kg, the above raw materials are as follows Sequentially add to the reaction kettle, stir and disperse until the material is uniform and there is no color difference.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com