Preparation technology of graphene oxide toughened alumina-based ceramic cutter

A preparation process and alumina technology, applied in the field of ceramic cutting tools, can solve the problems of discount of toughening effect, difficult dispersion of lamellae, etc., and achieve the effects of stable and uniform structure, increased strength and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

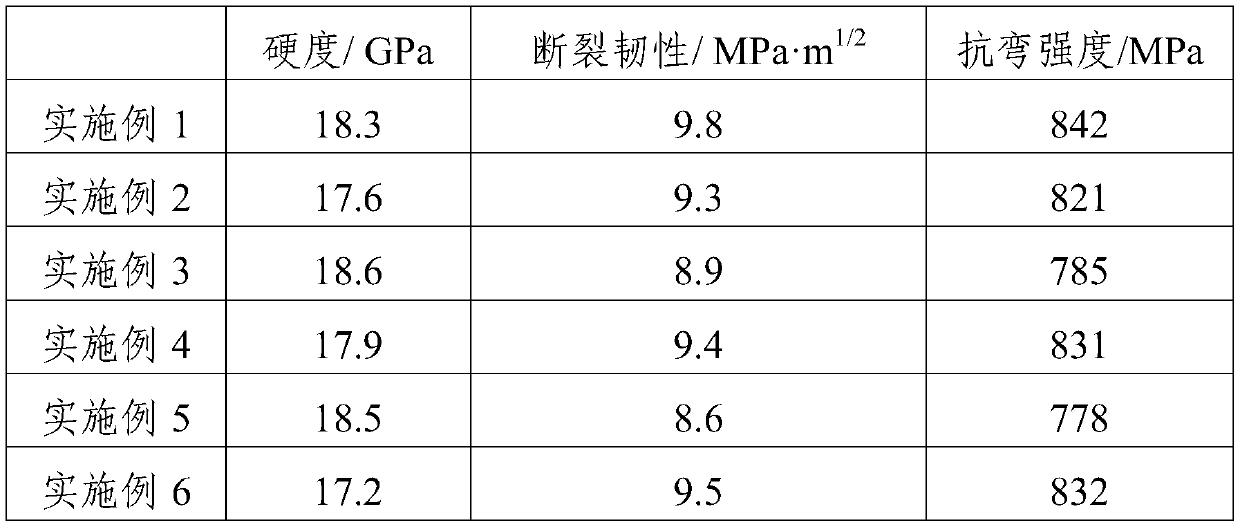

Examples

Embodiment 1

[0030] A preparation process for graphene oxide toughened alumina-based ceramic cutter, comprising the following steps:

[0031] (1) Add 0.7 parts of graphene oxide to absolute ethanol, add polyethylene glycol 4000 after mechanical stirring for 12 minutes, add 70 parts of α-alumina powder after mechanical stirring for 20 minutes, and perform ultrasonic vibration and mechanical stirring for 35 minutes at the same time , to get powder slurry I, the content of Polyethylene Glycol 4000 in the powder slurry I is 28g / L;

[0032] The thickness of graphene oxide is 1-3nm; the average particle size of α-alumina powder is 300nm.

[0033](2) Mix absolute ethanol with polyethylene glycol 2000, perform ultrasonic vibration and mechanical stirring at the same time, add 15 parts of β-SiC nanoparticles and 15 parts of TiC whiskers after 18 minutes, and carry out ultrasonic vibration and mechanical stirring for 50 minutes at the same time, Add 1 part of sintering aid, and carry out ultrasonic...

Embodiment 2

[0041] A preparation process for graphene oxide toughened alumina-based ceramic cutter, comprising the following steps:

[0042] (1) Add 0.5 parts of graphene oxide to absolute ethanol, add polyethylene glycol 5000 after mechanical stirring for 15 minutes, add 70 parts of α-alumina powder after mechanical stirring for 18 minutes, and perform ultrasonic vibration and mechanical stirring for 40 minutes at the same time , to get powder slurry I, the content of polyethylene glycol 5000 in the powder slurry I is 30g / L;

[0043] The thickness of graphene oxide is 0.5-2nm; the average particle size of α-alumina powder is 400nm.

[0044] (2) Mix absolute ethanol with polyethylene glycol 2000, perform ultrasonic vibration and mechanical stirring at the same time, add 15 parts of β-SiC nanoparticles and 13 parts of TiC whiskers after 15 minutes, and carry out ultrasonic vibration and mechanical stirring for 60 minutes at the same time, Add 0.7 part of sintering aid, and carry out ultra...

Embodiment 3

[0052] A preparation process for graphene oxide toughened alumina-based ceramic cutter, comprising the following steps:

[0053] (1) Add 0.3 parts of graphene oxide to absolute ethanol, add polyethylene glycol 4000 after mechanical stirring for 10 minutes, add 60 parts of α-alumina powder after mechanical stirring for 15 minutes, and perform ultrasonic vibration and mechanical stirring for 30 minutes at the same time , to get powder slurry I, the content of Polyethylene Glycol 4000 in the powder slurry I is 22g / L;

[0054] The thickness of graphene oxide is 3-5nm; the average particle size of α-alumina powder is 200nm.

[0055] (2) Mix absolute ethanol with polyethylene glycol 3000, perform ultrasonic vibration and mechanical stirring at the same time, add 10 parts of β-SiC nanoparticles and 18 parts of TiC whiskers after 20 minutes, and perform ultrasonic vibration and mechanical stirring for 40 minutes at the same time, Add 1.3 parts of sintering aid, and carry out ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com