Method of preparing iron oxide red from specularite

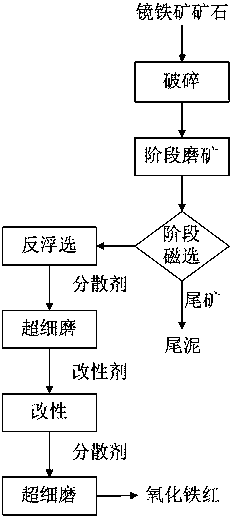

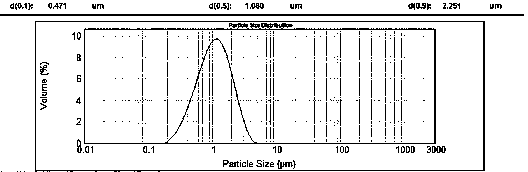

A technology of iron oxide red and mirror iron ore, which is applied in iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve the problems of high impurity content, poor performance of iron red products, and environmental pollution by waste acid wastewater. , to achieve the effect of increasing specific surface area, uniform particle size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

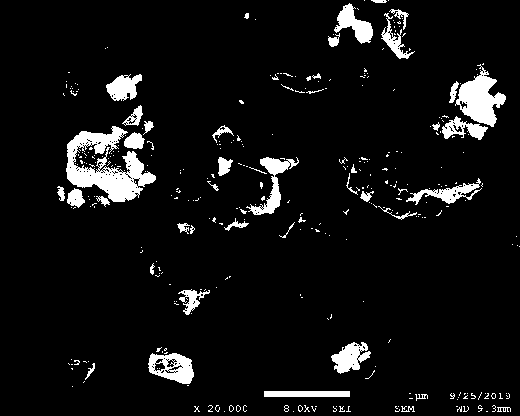

[0037] Main raw material of the present invention: specularite, the iron oxide grade of this specularite is 43.32%, SiO 2 Content 53.12%, MgO content 0.43%, Al 2 o 3 The content is 2.45%, and the CaO content is 0.12%. The specularite particle size distribution is uneven, and it is mainly distributed in the gangue minerals in strips.

[0038] The main supporting equipment is jaw crusher, roller crusher, ball mill, weak magnetic separator, strong magnetic separator, vacuum filter, centrifuge, oven, etc.

[0039] A method for preparing iron oxide red from specularite, comprising the following specific steps:

[0040] Step 1: Crushing specularite ore with an iron oxide grade of 43.32% through a jaw crusher and a double-roller crusher, and returning the large particles of 15 mm or more obtained by screening to the crusher to continue crushing until the obtained ore particles are all below 15 mm. The small particles below 15mm are ball milled with a ball mill, and the grinding fi...

Embodiment 2

[0049] Main raw material of the present invention: specularite, the iron oxide grade of this specularite is 43.32%, SiO 2 Content 53.12%, MgO content 0.43%, Al 2 o 3 The content is 2.45%, and the CaO content is 0.12%. The specularite particle size distribution is uneven, and it is mainly distributed in the gangue minerals in strips.

[0050] The main supporting equipment is jaw crusher, roller crusher, ball mill, weak magnetic separator, strong magnetic separator, vacuum filter, centrifuge, oven, etc.

[0051] A method for preparing iron oxide red from specularite, comprising the following specific steps:

[0052] Step 1: Crushing specularite ore with an iron oxide grade of 43.32% through a jaw crusher and a double-roller crusher, and returning the large particles of 15 mm or more obtained by screening to the crusher to continue crushing until the obtained ore particles are all below 15 mm. The small particles below 15mm are ball milled with a ball mill, and the grinding fi...

Embodiment 3

[0061] Main raw material of the present invention: specularite, the iron oxide grade of this specularite is 43.32%, SiO 2 Content 53.12%, MgO content 0.43%, Al 2 o 3 The content is 2.45%, and the CaO content is 0.12%. The specularite particle size distribution is uneven, and it is mainly distributed in the gangue minerals in strips.

[0062] The main supporting equipment is jaw crusher, roller crusher, ball mill, weak magnetic separator, strong magnetic separator, vacuum filter, centrifuge, oven, etc.

[0063] A method for preparing iron oxide red from specularite, comprising the following specific steps:

[0064] Step 1: Crushing specularite ore with an iron oxide grade of 43.32% through a jaw crusher and a double-roller crusher, and returning the large particles of 15 mm or more obtained by screening to the crusher to continue crushing until the obtained ore particles are all below 15 mm. The small particles below 15mm are ball milled with a ball mill, and the grinding fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com