CuO nanosheet as well as preparation method and application thereof from top to bottom

A top-down, nanosheet technology, applied in the field of nanotechnology and electrocatalysis, can solve the problems of complex preparation methods and small output, and achieve the effects of good repeatability, low cost and high electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

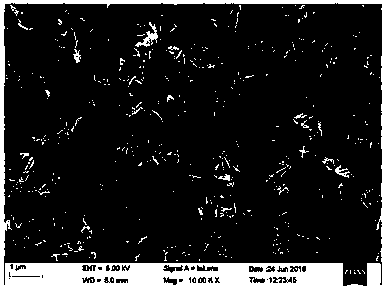

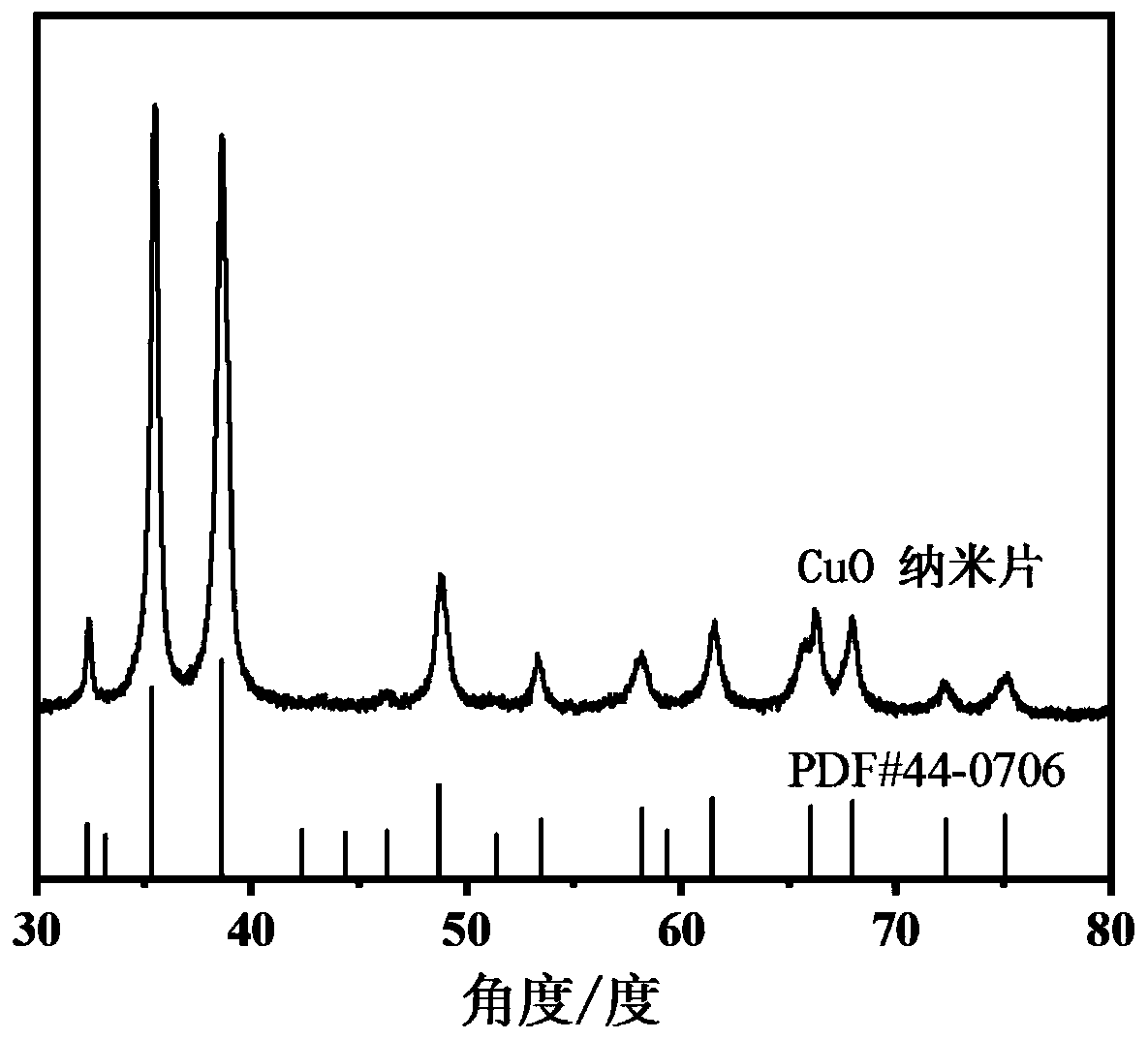

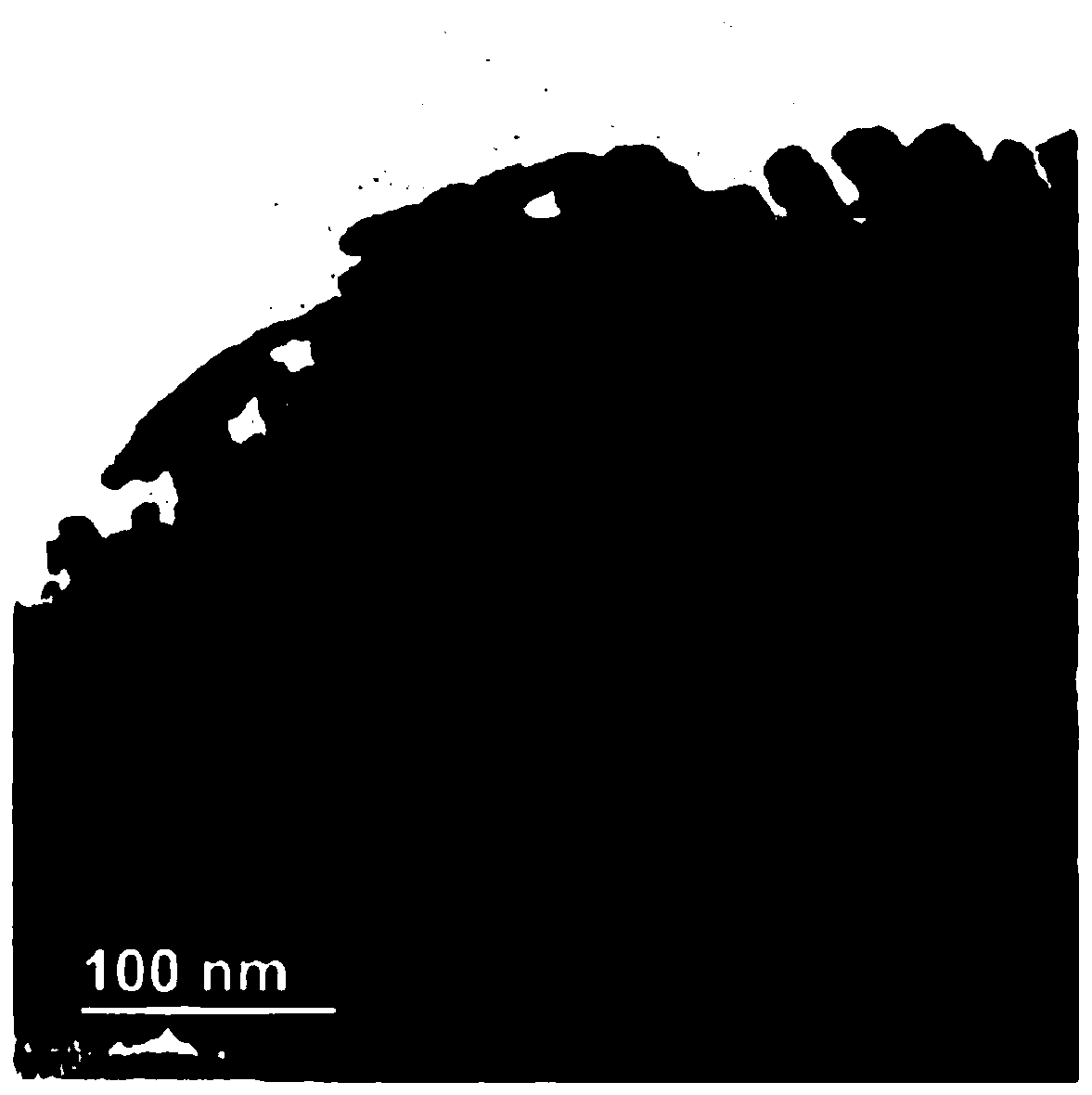

Image

Examples

Embodiment 1

[0037] A top-down preparation method of CuO nanosheets, comprising the following steps:

[0038] (1) Cut 0.25 g of copper foil into small pieces, immerse in acetone solution and ultrasonicate for 30 minutes to degrease the surface. The ultrasonic frequency is 20 kHz. L) soaked and washed for 3 times, taken out, washed with deionized water, and added to a mixed solution of ammonium persulfate and sodium hydroxide with a volume of 50 mL, in the mixed solution of ammonium persulfate and sodium hydroxide, The concentration of ammonium persulfate is 0.134 mol / L, the concentration of sodium hydroxide is 2.66 mol / L, ultrasonic treatment, the ultrasonic frequency of ultrasonic treatment is 20 kHZ, the time of ultrasonic treatment is 1h, filter and get the filtrate, filter the used filter The pore size of the net is 10 mesh, centrifuged at 7000 rpm for 3 minutes, and the precipitate is taken, then washed with deionized water and absolute ethanol for 3 times, and dried to obtain the pre...

Embodiment 2

[0042] A top-down preparation method of CuO nanosheets, comprising the following steps:

[0043](1) Cut 0.25 g of copper foil into small pieces, immerse in acetone solution and ultrasonicate for 30 minutes to degrease the surface. ) for 3 times, take it out, wash it with deionized water, add a volume of 50 mL of ammonium persulfate and sodium hydroxide mixed solution, in the mixed solution of ammonium persulfate and sodium hydroxide, over The concentration of ammonium sulfate is 0.1 mol / L, the concentration of sodium hydroxide is 2.5 mol / L, ultrasonic treatment, the ultrasonic frequency of ultrasonic treatment is 20 kHZ, the time of ultrasonic treatment is 0.5h, filter and get the filtrate, filter the used filter The pore size of the net is 10 mesh, centrifuged at 7000rpm for 3min, and the precipitate is taken, then washed with deionized water and absolute ethanol for 3 times, and dried to obtain the precursor. The drying temperature is 60°C. The drying time is 4h;

[0044] ...

Embodiment 3

[0046] A top-down preparation method of CuO nanosheets, comprising the following steps:

[0047] (1) Cut 0.25 g of copper foil into small pieces, immerse in acetone solution and ultrasonicate for 30 minutes for surface degreasing treatment. Soak and wash in medium for 3 times, take it out, wash with deionized water, add the mixed solution of ammonium persulfate and sodium hydroxide with a volume of 50 mL, in the mixed solution of ammonium persulfate and sodium hydroxide, persulfate The concentration of ammonium is 0.125 mol / L, the concentration of sodium hydroxide is 2.75 mol / L, ultrasonic treatment, the ultrasonic frequency of ultrasonic treatment is 30 kHZ, the time of ultrasonic treatment is 1h, filter and take the filtrate, filter the filter screen used The pore size is 10 mesh, centrifuged at 7000rpm for 3min, the precipitate is taken, and then washed with deionized water and absolute ethanol for 3 times, and dried to obtain the precursor. The drying temperature is 70°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com