Wear-resistant coating composition, wear-resistant welding wire and preparation method and application thereof

A technology of composition and coating, which is applied in the field of wear-resistant materials, can solve the problems of affecting the wear resistance of the surfacing layer metal, reducing the strength of diamond, and difficult wetting of diamond, so as to improve the atmosphere protection effect, reduce the linear expansion coefficient, Effect of improving brazing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

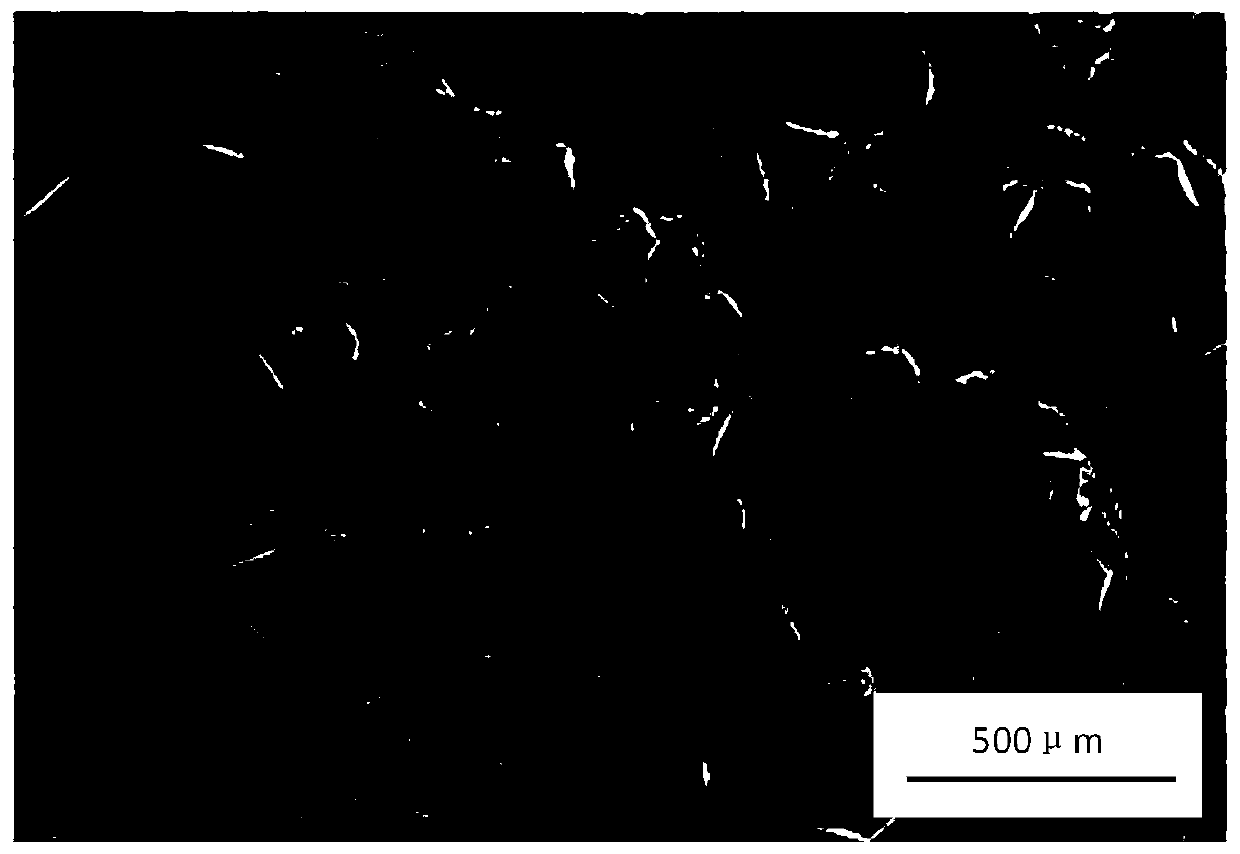

[0069] Surface activation of experimental example 1 diamond particles

[0070] (1) The diamond particles are placed in a sodium hydroxide solution with a concentration of 8g / L and 80°C, treated with ultrasonic vibration (40kHz, 30min), washed with deionized water until pH=7, and dried at 70°C;

[0071] (2) Place the dried diamond particles in a nitric acid solution (30wt.%), boil for 10 minutes, wash with deionized water until pH=7, and dry at 70°C;

[0072] (3) Soak the dried diamond particles in a mixed solution of ammonium molybdate (40g / L) and ammonium niobium oxalate (50g / L) at 60°C for 40min, remove, dry at 70°C, and set aside.

Embodiment 1

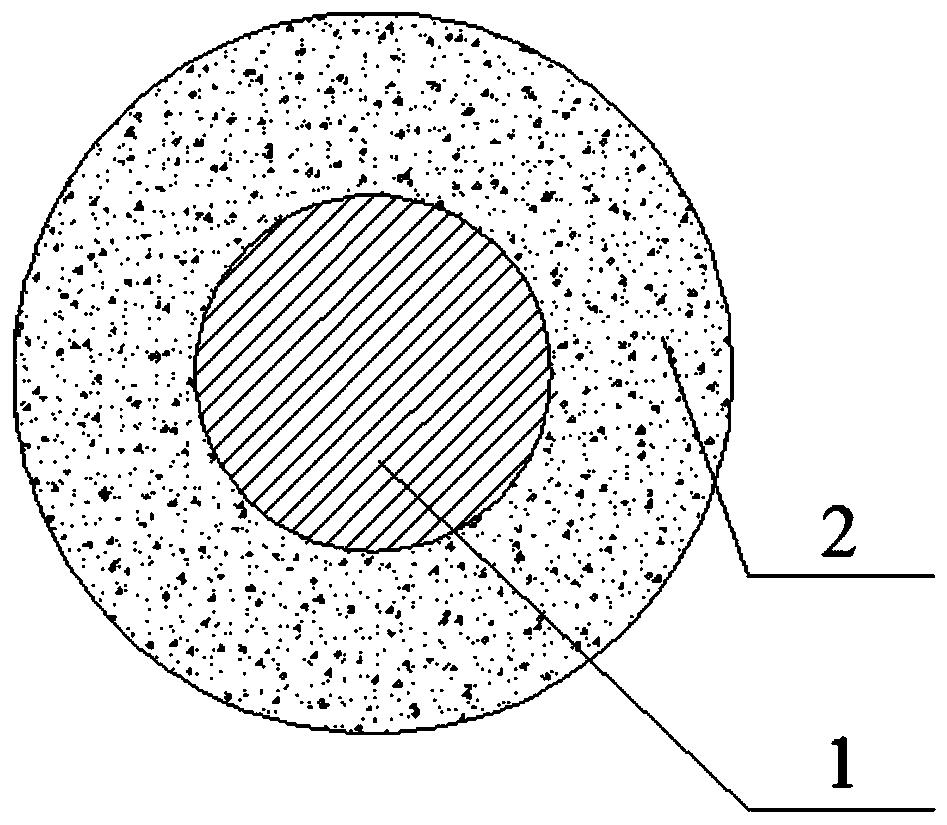

[0073] The preparation of embodiment 1 wear-resistant welding wire

[0074] 1 # Wear-resistant wire

[0075] The components of the wear-resistant coating composition are as shown in table 1:

[0076] Components and content of the wear-resistant coating composition of table 1

[0077] components surface activated diamond particles niobium oxide Molybdenum oxide Polymethylmethacrylate Nickel base alloy powder content 2wt.% 5wt.% 5wt.% 8wt.% BN 74 CrFeSiB balance

[0078] The welding core is pure nickel welding core with a diameter of Ф2.0mm and a length of 400mm.

[0079] The mixing of each material of the wear-resistant coating composition:

[0080] (1) Put niobium oxide, molybdenum oxide, polymethyl methacrylate, dimethyl carbonate and nickel-based alloy powder into a ball mill and mix them evenly according to the proportioning ratio;

[0081] The ball mill pot is made of ceramic material, the grinding ball is a high chromium c...

experiment example 2

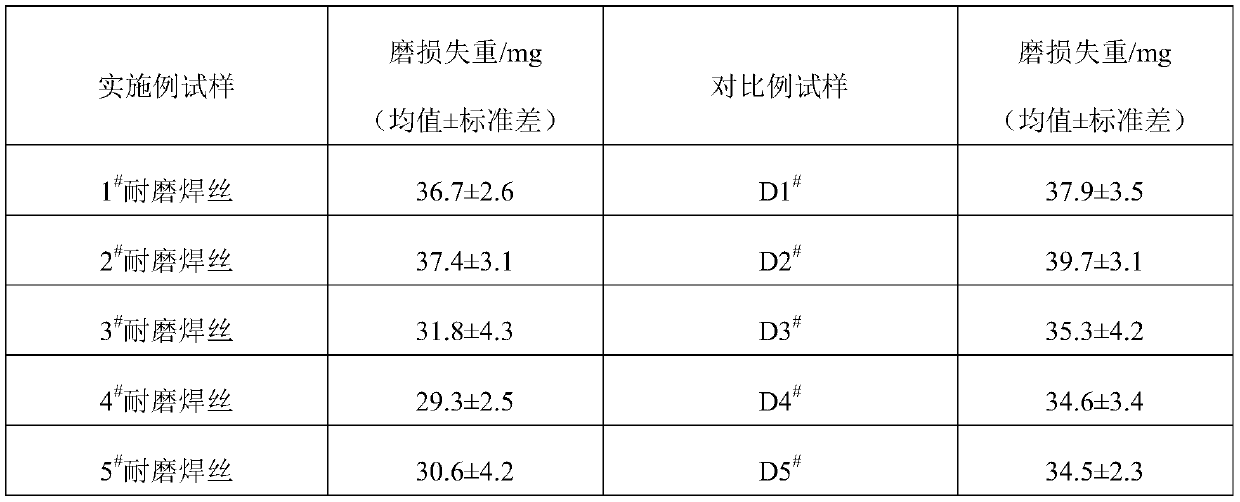

[0125] Experimental Example 2 Brazing application of wear-resistant welding wire

[0126] With the 1 prepared in embodiment 1 # ~5 # Wear-resistant welding wire is typical, and it is surfacing welding on the surface of 10mm thick Q235 steel plate. The surfacing welding conditions are as follows:

[0127] The welding polarity is DC reverse connection, the welding current is 300A~480A, the welding voltage is 23V~35V, and the welding overlap is 50%;

[0128] The protective atmosphere for surfacing welding is argon with a dew point of -55°C.

[0129] As a control, comparative example D1 # ~D5 # Respectively with the same as in Example 1 1 # ~5 # Amount of wear-resistant welding wire and treatment method Diamond powder and nickel-based alloy powder are directly brazed in an argon shielded furnace to coat a 10mm thick Q235 steel plate with a coating thickness of 0.5mm.

[0130] With the 1 prepared in embodiment 1 # ~5 # The wear-resistant welding wire is used for the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com