Low-temperature embedding aluminizing agent and powder embedding aluminizing method

An embedded infiltration, low temperature technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of the mechanical properties of the workpiece, the mechanical properties of the material, and the coarse grains of the substrate, so as to improve the viscosity. With the effect of performance, good quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A low-temperature embedding aluminizing agent, the raw material composition of the aluminizing agent is A1: 20%, CeO 2 : 0.5%, NH 4 Cl: 2%, A1 2 o 3 : 77.5%.

[0032] The preparation method of the above-mentioned low-temperature embedding aluminizing agent, the specific implementation steps are:

[0033] (1): Weigh the pure aluminum powder, nano ceria, activator and alumina according to the mass percentage; add the pure aluminum powder, nano ceria and alumina to the ball mill and mix for 2 hours;

[0034] (2): Add the weighed activator ammonium chloride, and continue mixing and stirring for 2h;

[0035] (3): Put the uniformly mixed powder into a crucible, and dry it in a muffle furnace at 300°C for 1 hour without air.

[0036] The aluminizing agent prepared in Example 1 is applied to the low-temperature powder embedding aluminizing method, and the specific implementation steps are:

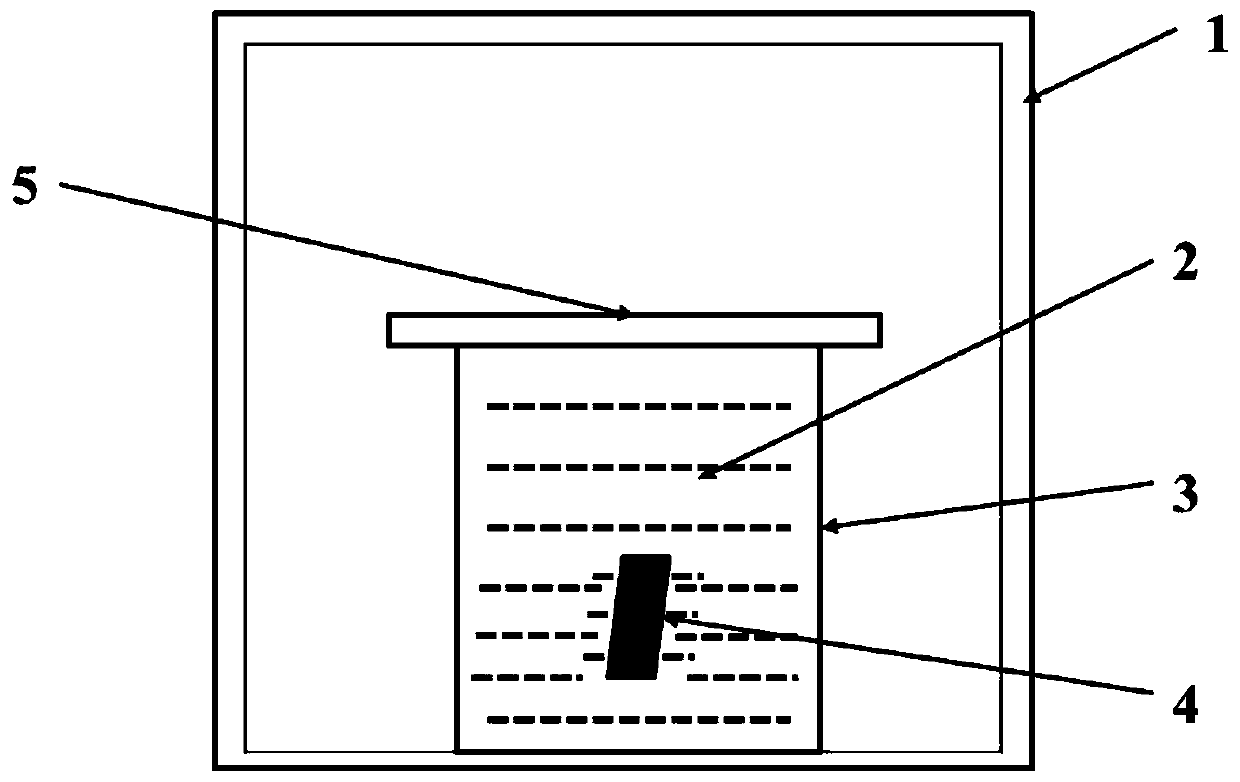

[0037] (1) Take a small amount of aluminizing agent and put it into the corundum ...

Embodiment 2

[0042] A low-temperature embedding aluminizing agent, the raw material composition of the aluminizing agent is A1: 30%, CeO 2 : 1%, NH 4 Cl: 3%, A1 2 o 3 : 66%.

[0043] The preparation method of the above-mentioned low-temperature embedding aluminizing agent, the specific implementation steps are:

[0044] (1): Weigh the pure aluminum powder, nano ceria, activator and alumina according to mass percentage; and add the pure aluminum powder, nano ceria and alumina to the ball mill and mix for 10h;

[0045] (2): Add the weighed activator ammonium chloride, and continue mixing and stirring for 3h;

[0046] (3): Put the uniformly mixed powder into a crucible, and dry it in a muffle furnace at 400°C for 2 hours without air.

[0047] The aluminizing agent prepared in Example 1 is applied to the low-temperature powder embedding aluminizing method, and the specific implementation steps are:

[0048] (1) Take a small amount of aluminizing agent and put it into the corundum crucibl...

Embodiment 3

[0054] A low-temperature embedding aluminizing agent, the raw material composition of the aluminizing agent is A1: 40%, CeO 2 : 2%, NH 4 Cl: 4%, A1 2 o 3 : 54%.

[0055] The preparation method of the above-mentioned low-temperature embedding aluminizing agent, the specific implementation steps are:

[0056] (1): Weigh the pure aluminum powder, nano ceria, activator and alumina according to the mass percentage; and add the pure aluminum powder, nano ceria and alumina to the ball mill and mix for 24h;

[0057] (2): Add the weighed activator ammonium chloride, and continue mixing and stirring for 5h;

[0058] (3): Put the uniformly mixed powder into a crucible, and dry it in a muffle furnace at 500°C for 3 hours without air.

[0059] The aluminizing agent prepared in Example 1 is applied to the low-temperature powder embedding aluminizing method, and the specific implementation steps are:

[0060] (1) Take a small amount of aluminizing agent and put it into the corundum cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com