Food packaging material capable of keeping fresh and resisting bacteria for long time

A food packaging, long-term technology, applied in packaging, wrapping paper, biological packaging, etc., can solve the problems of potential safety hazards, limited application, easy leakage of antibacterial packaging film antibacterial agents, etc., to enhance mechanical properties, biological phase Good capacitance and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

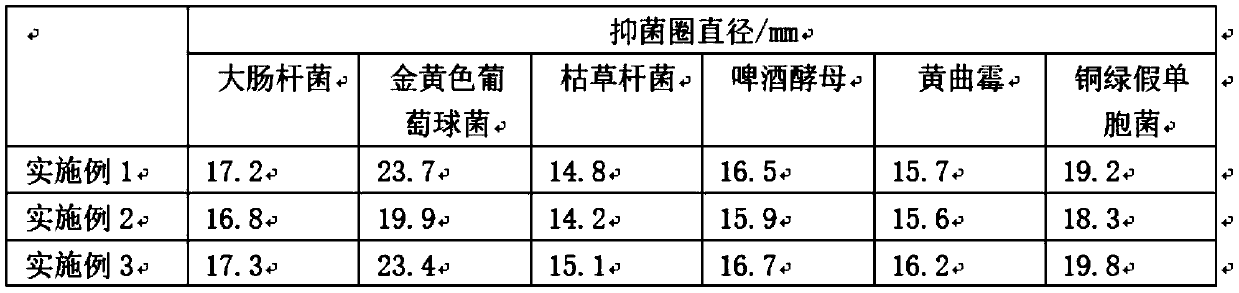

Embodiment 1

[0044] A food packaging material capable of long-term preservation and antibacterial. The material is calculated in parts by weight and includes the following ingredients:

[0045] 50 parts of polylactic acid, 20 parts of polycaprolactone, 10 parts of polymethylethylene carbonate, 15 parts of chitosan, 3 parts of gelatin, 0.5 parts of fennel leaf extract, 1.5 parts of Ti powder, AlCl 3 0.75 parts of granules and 2.5 parts of tributyl citrate.

[0046] The preparation method of the above food packaging material is:

[0047] Step 1. Prepare fennel leaf extract:

[0048] (1) Grind the dried fennel leaves into powder, mix well with deionized water, boil, and filter to obtain supernatant A and solid B; add deionized water to solid B again, mix well, boil, and filter to obtain Supernatant C; Combine supernatant A and supernatant C to obtain a combined liquid, and concentrate to obtain an fennel leaf extract;

[0049] Wherein, the solid-to-liquid ratio of fennel leaf to deionized water is 1:1...

Embodiment 2

[0071] A food packaging material capable of long-term preservation and antibacterial. The material is calculated in parts by weight and includes the following ingredients:

[0072] 30 parts of polylactic acid, 30 parts of polycaprolactone, 15 parts of polymethylethylene carbonate, 10 parts of chitosan, 2 parts of gelatin, 0.1 part of fennel leaf extract, 1 part of Ti powder, AlCl 3 0.5 parts of granules and 2 parts of synthetic vegetable esters.

[0073] The preparation method of the above food packaging material is:

[0074] Step 1. Prepare fennel leaf extract:

[0075] (1) Grind the dried fennel leaves into powder, mix well with deionized water, boil, and filter to obtain supernatant A and solid B; add deionized water to solid B again, mix well, boil, and filter to obtain Supernatant C; Combine supernatant A and supernatant C to obtain a combined liquid, and concentrate to obtain an fennel leaf extract;

[0076] Wherein, the solid-liquid ratio of the fennel leaf and deionized water i...

Embodiment 3

[0098] A food packaging material capable of long-term preservation and antibacterial. The material is calculated in parts by weight and includes the following ingredients:

[0099] 40 parts of polylactic acid, 20 parts of polycaprolactone, 15 parts of polymethylethylene carbonate, 15 parts of chitosan, 5 parts of gelatin, 1 part of fennel leaf extract, 2 parts of Ti powder, AlCl 3 1 part of granules and 3 parts of tributyl citrate.

[0100] The preparation method of the above food packaging material is:

[0101] Step 1. Prepare fennel leaf extract:

[0102] (1) Grind the dried fennel leaves into powder, mix well with deionized water, boil, and filter to obtain supernatant A and solid B; add deionized water to solid B again, mix well, boil, and filter to obtain Supernatant C; Combine supernatant A and supernatant C to obtain a combined liquid, and concentrate to obtain an fennel leaf extract;

[0103] Wherein, the solid-liquid ratio of the fennel leaf to deionized water is 1:20; the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com