Cast ingot manufacturing device and method

A technology for manufacturing equipment and ingots, which is applied in the field of preparing high-quality ingots, can solve the problems of low efficiency and high cost, and achieve the effect of wide sources, low cost and wide selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

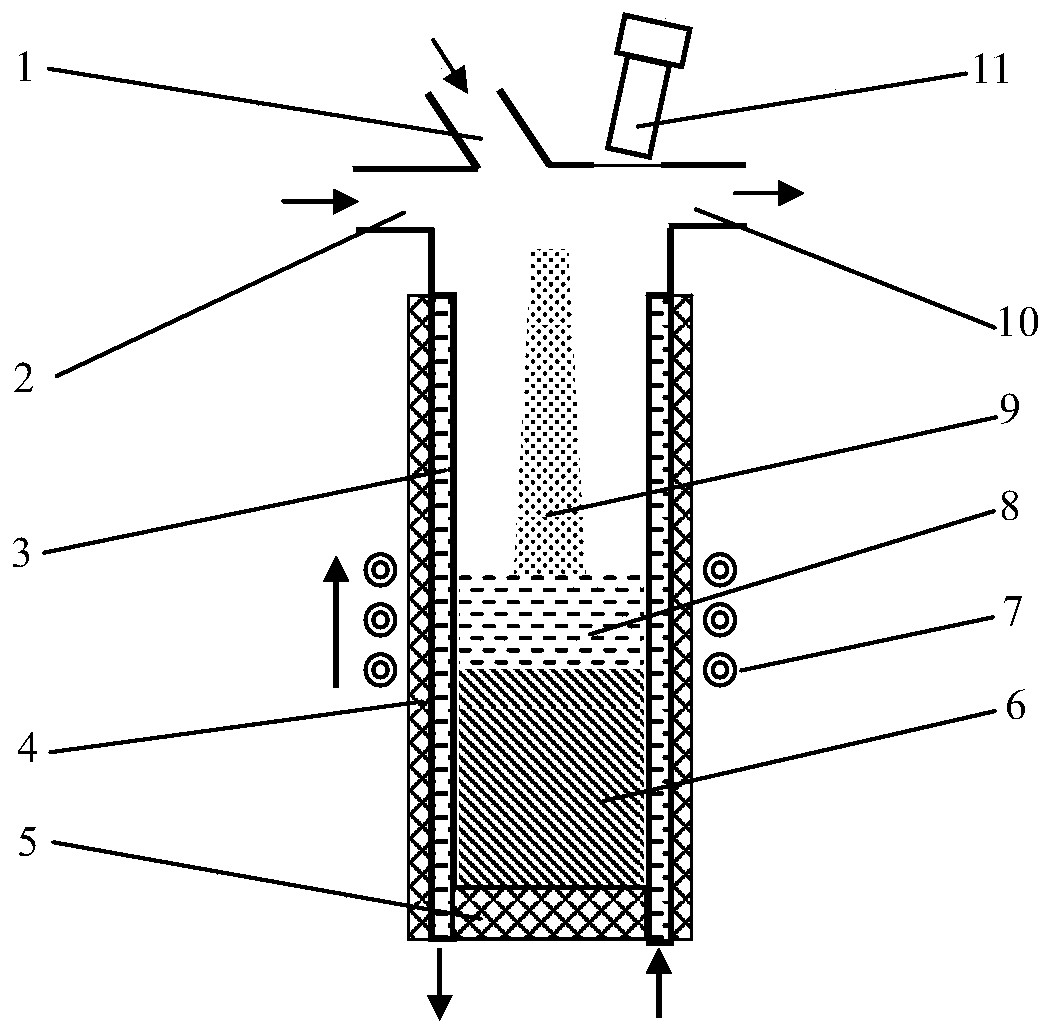

Embodiment 1

[0039]Taking GCr15 bearing steel as an example, evenly mix sponge iron powder, high-purity recarburizer, high-carbon ferrochrome powder, a small amount of ferrosilicon, ferromanganese powder and slag to ensure that the raw material composition meets the requirements of GCr15 bearing steel composition, and the slag agent accounts for 2-10% of the total mass, granulated and dried for later use; put a small amount of GCr15 bearing steel scrap steel and mold slag in the cold crucible 3, and pass the protective slag into the cold crucible 3 covered with the sealing layer 4 through the air inlet 2 Gas, start the induction heater 7 to heat, after the GCr15 bearing steel scrap is heated and melted, the induction heater 7 is clamped by the clamping device to move upward at a constant speed, and the feeding mechanism sends the raw materials into the molten pool. As the molten pool continues to rise, The lower part of the melt continues to solidify and eventually forms a complete ingot. ...

Embodiment 2

[0041] 304 stainless steel ingot manufacturing plan, 304 stainless steel scrap (steel shavings, blanking waste, etc.) is degreased, crushed, mixed, ball-pressed and other processes to form uniform particles or balls and other furnace materials, which are dried and used for later use; before smelting A certain amount of 304 stainless steel scrap steel and protective slag are put into the cold crucible 3, and the protective gas is introduced, and the induction heater 7 is started to heat. After the material is melted, the aforementioned prepared charge is added, and the induction heater is clamped by the clamping device 7 moves upward at a constant speed, and the charging speed is controlled by the temperature sensor 11 to keep the smelting process stable. After the induction coil reaches the top of the crucible, remove the coil after a period of heat preservation, open the crucible, and take out the ingot. The obtained ingot is tested, and it is found that the non-metallic incl...

Embodiment 3

[0043] 201 stainless steel ingot manufacturing plan, the 201 stainless steel scrap (steel scrap, blanking waste, etc.) is degreased, crushed, mixed, ball-pressed and other processes to form uniform particles or pellets and other furnace materials, which are dried and used for later use; A certain amount of 201 stainless steel scrap steel and protective slag are put into the cold crucible 3, and the protective gas is introduced, and the induction heater 7 is started for heating. Moving upward at a uniform speed, the charging speed is controlled by the temperature sensor 11 to keep the melting process stable. After the induction coil reaches the top of the crucible, remove the coil after a period of heat preservation, open the crucible, and take out the ingot. The obtained ingot is tested, and it is found that the non-metallic inclusions are less than grade 2, the surface is smooth, there is no obvious visible defect, the internal structure is dense, no shrinkage cavity, loose, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com