Lithium ion battery anode and preparation method thereof

A lithium-ion battery and cathode technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as low efficiency, reduced agglomeration size, heavy weight, etc., achieve simple and convenient preparation process, prevent liquefaction, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

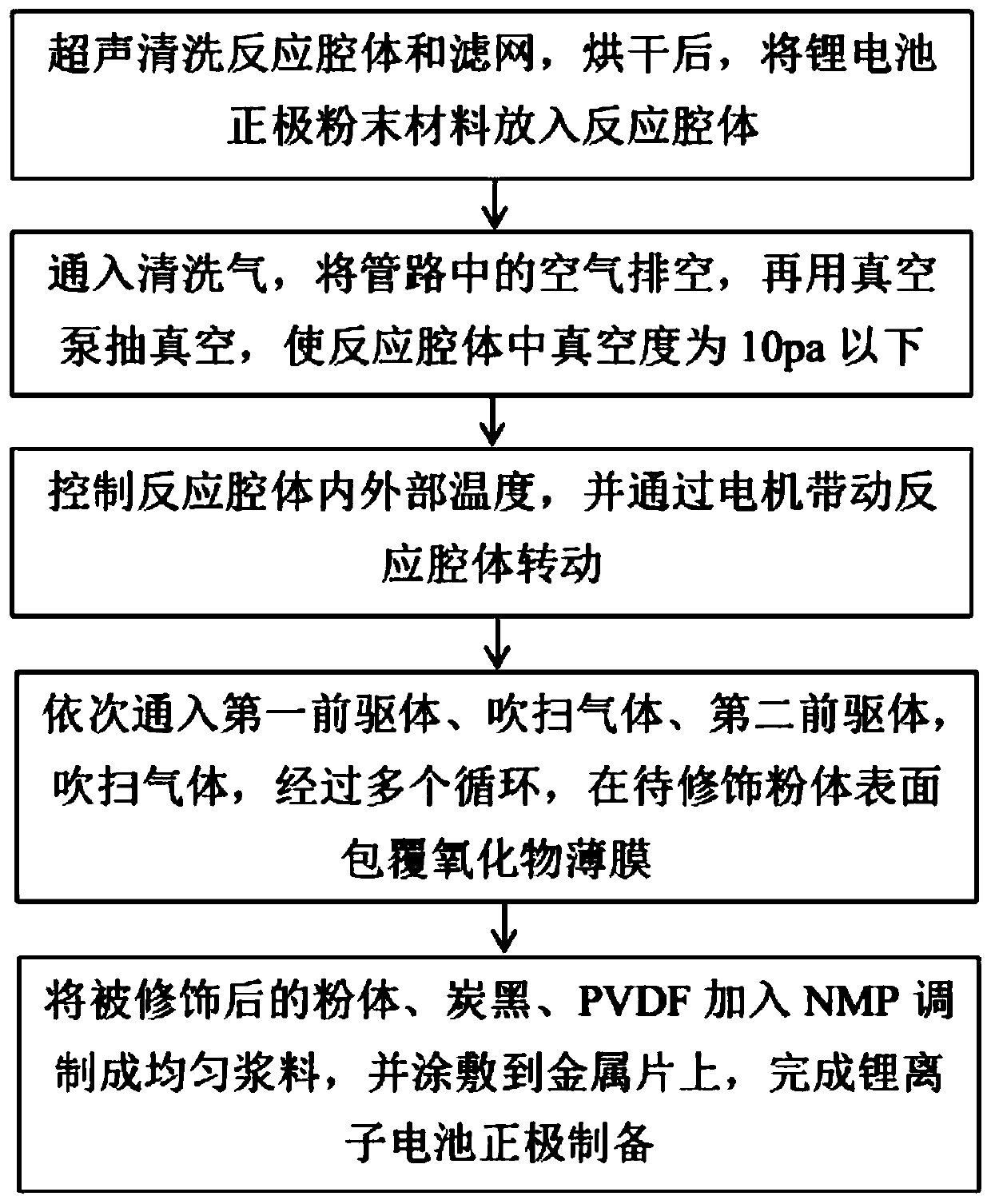

Method used

Image

Examples

Embodiment 1

[0040] In order to prepare a high energy storage cathode material for lithium batteries, LiCoO 2 The powder is placed in a centrifugal fluidized atomic layer deposition equipment to deposit an aluminum oxide film, because the conductivity of the aluminum oxide film is poor, the dielectric effect is small, and LiCoO 2 It has the characteristics of large specific capacity and stable structure, so it can be used as a high-energy storage lithium battery cathode material. The specific steps are as follows:

[0041] S1 Ultrasonic treatment of the reaction chamber and the filter screen in it for 30 minutes, after cleaning, connect the reaction chamber and the filter screen with glue, and connect the components with bolts;

[0042] S2 LiCoO 2 The powder is placed in the reaction chamber of the centrifugal atomic layer deposition equipment, and the stepping motor is adjusted to rotate the reaction chamber at a speed of 400r / min. The heating source and the outside of the reaction chamb...

Embodiment 2

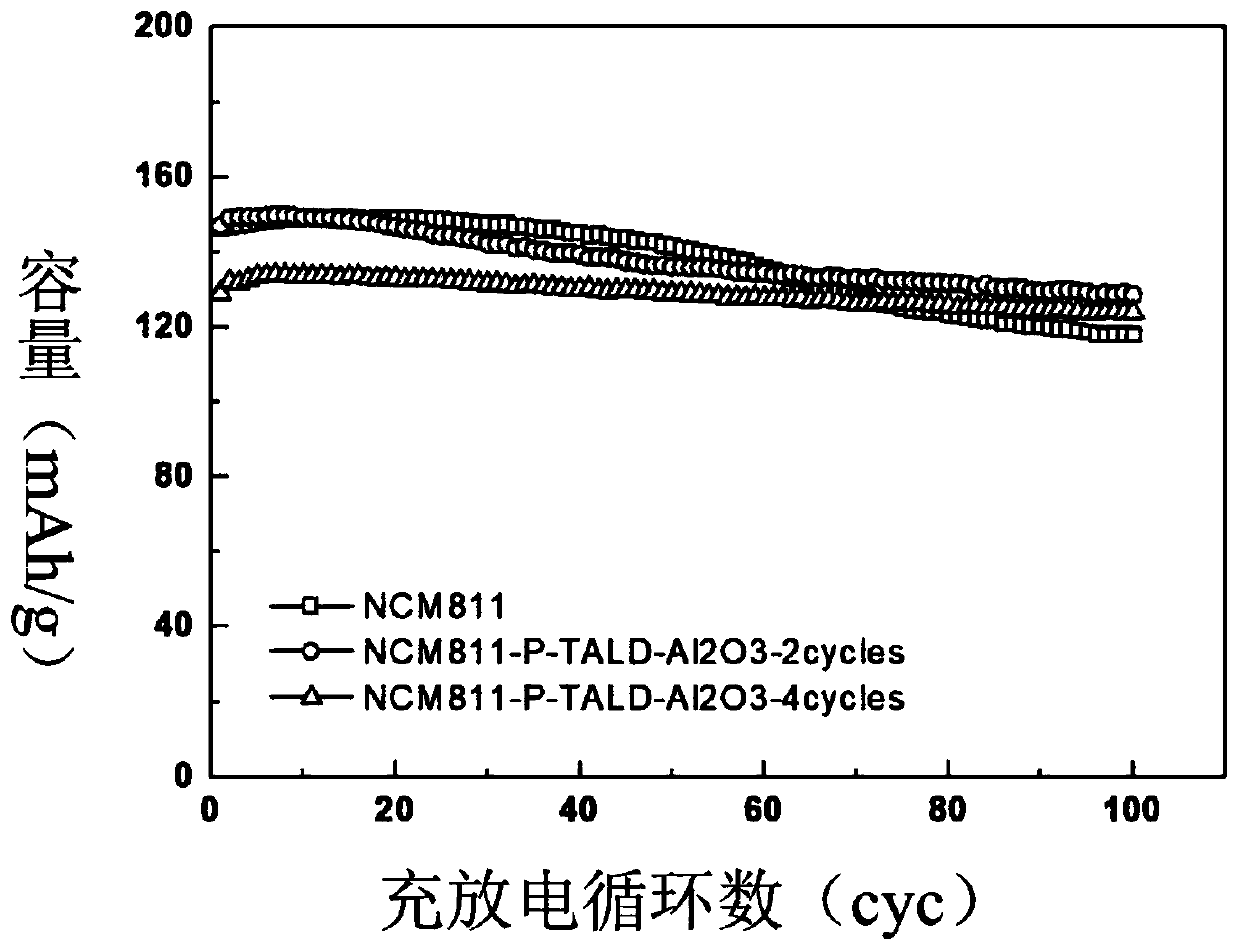

[0045] In order to prepare a fast-charge lithium battery cathode material, NCM811 powder is placed in a centrifugal fluidized atomic layer deposition equipment to deposit a composite film of aluminum oxide and zinc oxide, because the composite film of aluminum oxide and zinc oxide has a dielectric effect and conductivity Strong, can make charging and discharging faster and more efficient, so it can be used as a fast-charging lithium battery cathode material, the specific steps are as follows:

[0046] S1 Ultrasonic treatment of the reaction chamber and the filter screen in it for 30 minutes, after cleaning, connect the reaction chamber and the filter screen with glue, and connect the components with bolts;

[0047] S2 Place the NCM811 powder in the reaction chamber of the centrifugal atomic layer deposition equipment, adjust the stepping motor to rotate the reaction chamber at a speed of 300r / min, heat the heating source and the outside of the reaction chamber to 200°C, and hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com