A kind of preparation method of silver gallium indium selenide/oxide film electrode

A technology of oxide thin film and oxide, which is applied in the field of solar cell materials to achieve the effects of uniform particles, improved battery performance, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of TiO on ITO 2 Porous film (ITO / TiO 2 )

[0042] Screen-print titanium dioxide slurry (P25) on ITO with a thickness of about 9 μm, heat and calcinate in a muffle furnace at 500°C for 30 minutes to obtain TiO 2 Porous film (ITO / TiO 2 ).

[0043] (2) Synthesis of silver gallium indium selenide nanoparticles coated with oleylamine

[0044] Add 0.3mmol of silver acetate, 0.2mmol of gallium acetate, and 0.1mmol of indium acetate into a three-necked flask containing 10mL of oleylamine and 5mL of octadecene, heat to 130°C with nitrogen gas, and vacuumize for 30min. Infuse nitrogen gas to raise the temperature to 170°C, and dissolve 0.6mmol selenium powder in 2mL DPP, quickly inject into the above reaction solution, and react at 170°C for 10min. Remove heat source and rapidly cool to room temperature. Add an appropriate amount of cyclohexane to wash, precipitate and centrifuge with methanol, and then disperse the silver gallium indium selenide nanoparticl...

Embodiment 2

[0050] (1) Preparation of TiO on Ti sheet 2 Porous film (Ti / TiO 2 ), the method is the same as in Example 1 (1), except that the substrate is changed to a Ti sheet.

[0051] (2) Synthesis of silver gallium indium selenide nanoparticles coated with oleylamine

[0052]Add 0.3mmol of silver acetylacetonate, 0.225mmol of gallium acetylacetonate, and 0.075mmol of indium acetylacetonate into a three-necked flask containing 10mL of oleylamine and 5mL of octadecene, heat to 130°C with nitrogen gas, and vacuumize for 30min. Infuse nitrogen gas to raise the temperature to 180°C, and dissolve 0.6mmol selenium powder in 2mL DPP, quickly inject into the above reaction solution, and react at 180°C for 7min. Remove heat source and rapidly cool to room temperature. Add an appropriate amount of cyclohexane to wash, precipitate and centrifuge with methanol, and then disperse the silver gallium indium selenide nanoparticles in chloroform.

[0053] Steps (3)-(5) Referring to Example 1 (3)-(5)...

Embodiment 3

[0055] (1) Preparation of TiO on FTO 2 Porous film (FTO / TiO 2 ), the method is the same as in Example 1 (1), except that the substrate is changed into FTO.

[0056] (2) Synthesis of silver gallium indium selenide nanoparticles coated with oleylamine

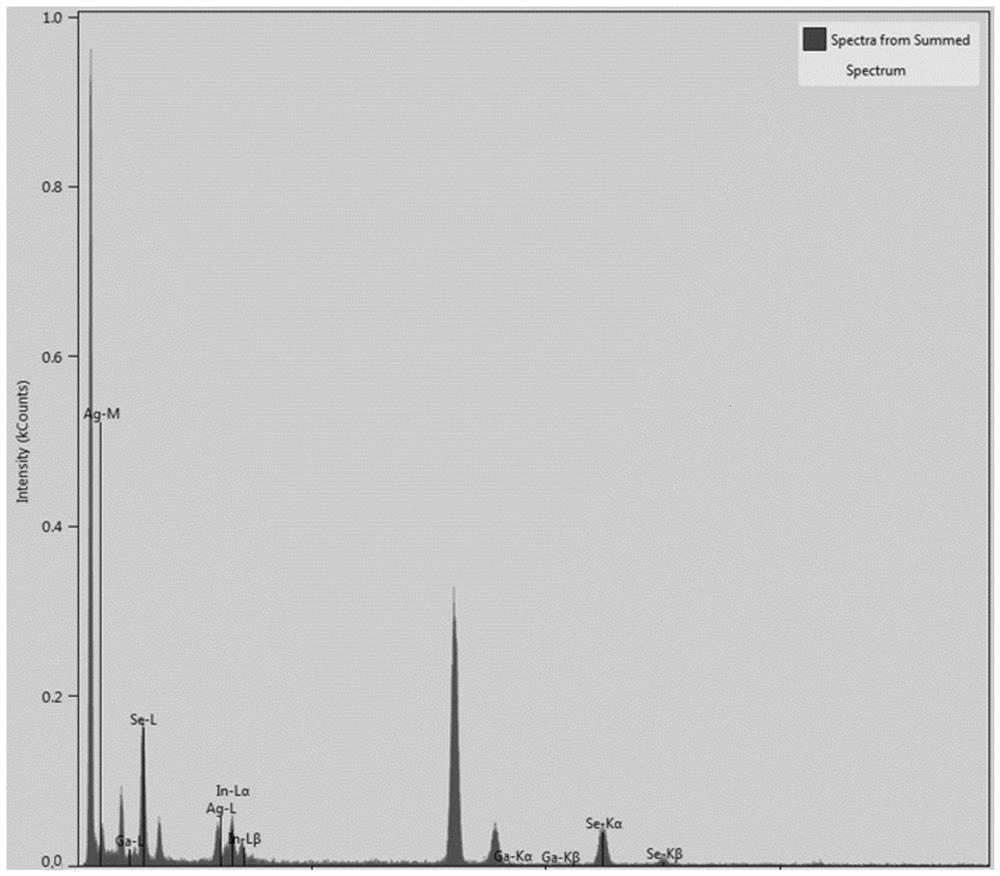

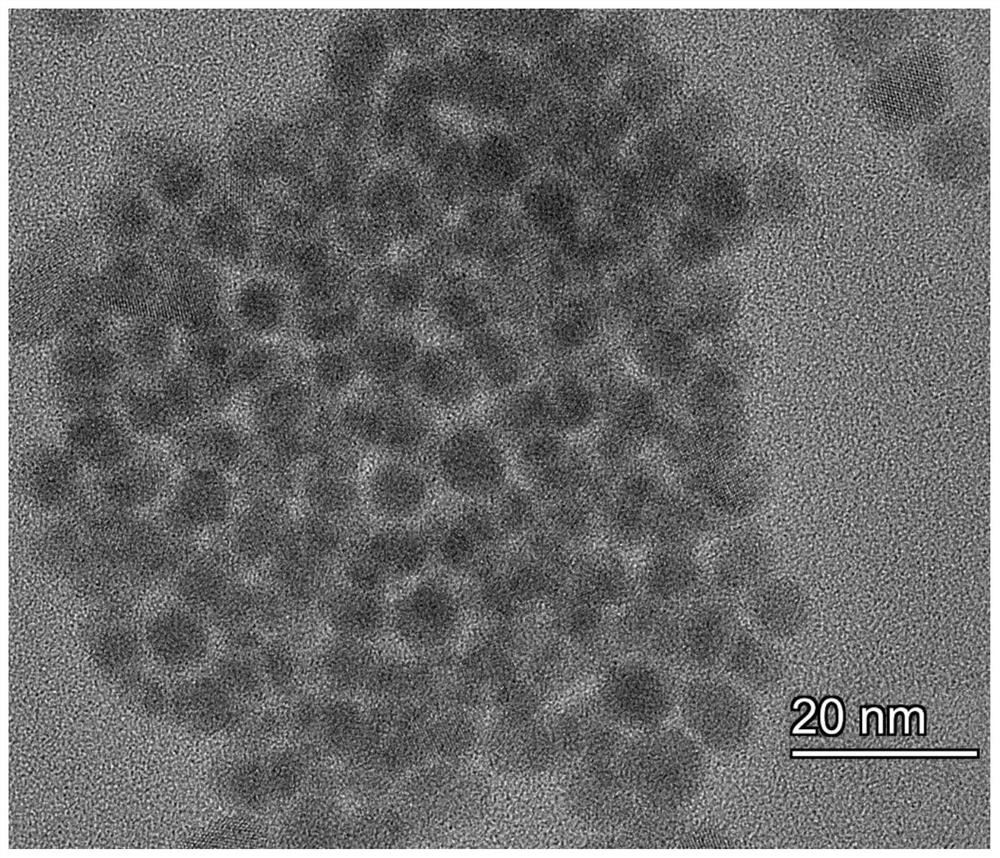

[0057] Add 0.3mmol of silver acetate, 0.24mmol of gallium acetylacetonate, and 0.06mmol of indium acetate into a three-necked flask containing 10mL of oleylamine and 5mL of octadecene, heat to 130°C with nitrogen gas, and vacuumize for 30min. Infuse nitrogen gas to raise the temperature to 190°C, and dissolve 0.6mmol selenium powder in 2mL DPP, quickly inject into the above reaction solution, and react at 190°C for 5min. Remove heat source and rapidly cool to room temperature. Add an appropriate amount of cyclohexane to wash, precipitate and centrifuge with methanol, and then disperse the silver gallium indium selenide nanoparticles in chloroform. Its TEM image is shown in figure 1 , EDS diagram see figure 2 .

[0058] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com