A kind of preparation method of polyoxometalate lithium ion battery electrode material

A polyoxometalate and lithium-ion battery technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., to achieve the effect of novel structure and low requirements for synthesis equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

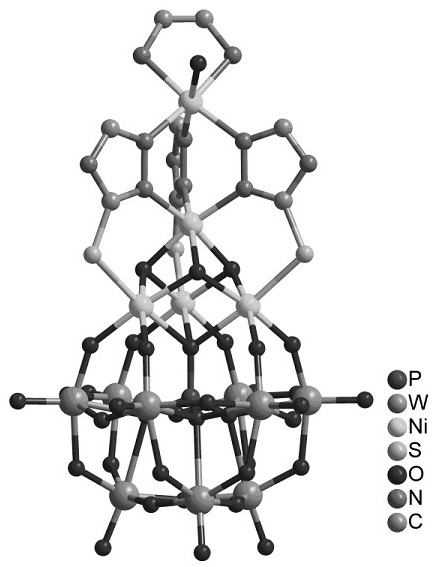

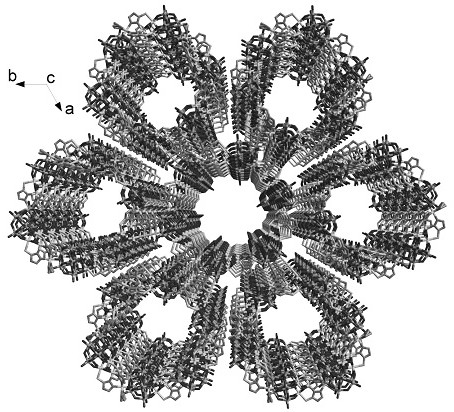

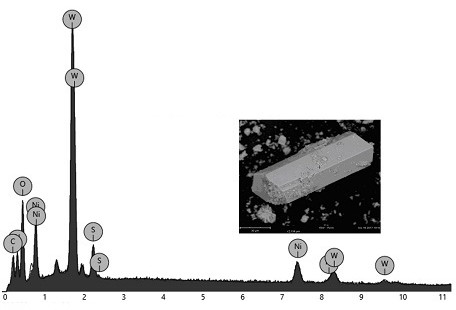

[0035] Na[α-PW 9 o 34 ].nH2 O (300mg), Ni(NO 3 ) 2 .6H 2 O (350mg) and 3-mercapto-1,2,4-triazole (50mg) were added to 4ml of 0.5mol / L sodium acetate solution. Add 0.2ml of ethylenediamine to the above solution, stir at room temperature for 30 minutes, then transfer to a 25ml reaction kettle, and react at 170°C for three days. After the reaction was completed and cooled to room temperature, it was filtered and washed twice with water and ethanol respectively to obtain a green product. The product was vacuum dried at 100° C. for 12 hours to obtain a dark green solid powder. Pass the dried Ni-POM through a 300-mesh sieve. Ni-POM, PVDF, and KS6 were configured into a mixture according to the mass ratio of 60:10:30, NMP was added as a solvent, and after stirring for 2 hours, a lithium-ion battery electrode slurry was prepared. The electrode viscous slurry was coated on a 12 μm copper foil with a coating thickness of 50 μm, and dried at 100° C. for 12 hours to obtain a lithiu...

Embodiment 2

[0037] Example 2: Na[α-PW 9 o 34 ].nH 2 The amount of O added is 1500mg; Ni(NO 3 ) 2 .6H 2 The amount of O added was 1750 mg, the amount of 3-mercapto-1,2,4-triazole added was 250 mg; the amount of ethylenediamine added was 1 ml; the concentration of sodium acetate used for dissolution was 1 mol / l, and the volume was 20 ml. Other operating steps are close to Example 1.

Embodiment 3

[0039] Na[α-PW 9 o 34 ].nH 2 O (600mg), Ni(NO 3 ) 2 .6H 2 O (700mg) and 3-mercapto-1,2,4-triazole (100mg) were added to 8ml of 0.5mol / L sodium acetate solution. Add 0.4ml of ethylenediamine to the above solution, stir at room temperature for 30 minutes, then transfer to a 25ml reaction kettle, and react at 170°C for three days. After the reaction was completed and cooled to room temperature, it was filtered and washed twice with water and ethanol respectively to obtain a green product. The product was vacuum dried at 100° C. for 12 hours to obtain a dark green solid powder. Pass the dried Ni-POM through a 300-mesh sieve. Ni-POM, PVDF, and KS6 were configured into a mixture according to the mass ratio of 70:5:25, and NMP was added as a solvent, and stirred for 2 hours to prepare a lithium-ion battery electrode slurry. The electrode viscous slurry was coated on a 12 μm copper foil with a coating thickness of 50 μm, and dried at 100° C. for 12 hours to obtain a lithium io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com