Preparation method of porous nanofiber membrane loaded atomic-scale active site catalyst

A nanofiber membrane and active site technology, which is applied in the field of preparation of atomic-level active site catalysts, can solve the problems of difficult direct recovery, pressure drop of catalytic bed, poor mechanical properties, etc., and achieve narrow pore size distribution and strong synergistic effect , enhance the effect of the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

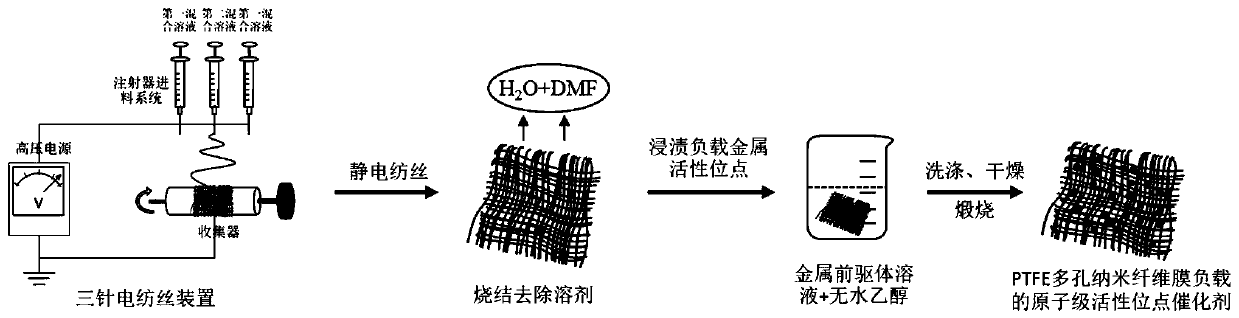

[0031] Such as figure 1 A preparation method of an atomic-level active site catalyst supported by a porous nanofiber membrane comprises the following steps:

[0032] (1) prepare PTFE porous nanofiber membrane, comprise the following steps:

[0033] In the first step, the surfactant powder is dissolved in distilled water at 40-100°C, and continuously stirred for 6-10 hours to obtain an aqueous solution with a mass fraction of surfactant of 5-15 wt%, and cooled to 20-30°C; The surfactant can be one of polyvinyl alcohol (PVA), polyethylene oxide (PEO) or ethylene phthalate (PET) and the like.

[0034]In the second step, adding PTFE emulsion and boric acid solid powder containing 60% solids to the aqueous solution, the mass ratio of PTFE and surfactant is 2:1~12:1, the mass ratio of surfactant and boric acid The ratio is 1:0.001-1:0.003, and the stirring is continued for 2-5 hours to obtain the first mixed solution.

[0035] In the third step, PAN (polyacrylonitrile) is dissolv...

Embodiment 1

[0044] Preparation of Pt-PTFE / PVA atomic-level active site catalyst:

[0045] (1) prepare PTFE / PVA porous nanofiber membrane, comprise the following steps:

[0046] In the first step, polyvinyl alcohol (PVA) powder was dissolved in distilled water at 80°C, and stirred continuously for 8 hours to obtain an aqueous solution with a mass fraction of PVA of 10 wt%, and cooled to 25°C;

[0047] In the second step, adding PTFE emulsion and boric acid BA solid powder containing 60% solids to the aqueous solution, the mass ratio of PTFE and surfactant is 6:1, and the mass ratio of PVA and BA is 1:0.0015 , and continuously stirred for 3h to obtain the first mixed solution.

[0048] In the third step, PAN (polyacrylonitrile) is dissolved in N,N dimethylformamide to form a second mixed solution with a mass fraction of PAN of 10 wt%.

[0049] The fourth step is to prepare PTFE / PVA porous nanofiber membrane by electrospinning method. The steps are: place the first mixed solution in the sy...

Embodiment 2

[0062] Preparation of Pd-PTFE / PEO atomic-level active site catalyst:

[0063] (1) Prepare PTFE / PEO porous nanofiber membrane, the steps are as follows:

[0064] In the first step, polyethylene oxide (PEO) powder was dissolved in distilled water at 40°C, and stirred continuously for 10 hours to obtain an aqueous solution with a mass fraction of PEO of 5 wt%, and cooled to 20°C;

[0065] In the second step, in the aqueous solution, adding PTFE emulsion and boric acid BA solid powder containing 60% solid mass, the mass ratio of PTFE and PEO is 2:1, and the mass ratio of PEO and BA is 1:0.001, and Stirring was continued for 2 h to obtain the first mixed solution.

[0066] In the third step, PAN (polyacrylonitrile) is dissolved in N,N dimethylformamide to form a second mixed solution with a mass fraction of PAN of 5 wt%.

[0067] The fourth step is to prepare PTFE / PVA porous nanofiber membrane by electrospinning method. The steps are: place the first mixed solution in the syringe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com