A catalyst for biodiesel hydrodeoxygenation reaction and its preparation method and application

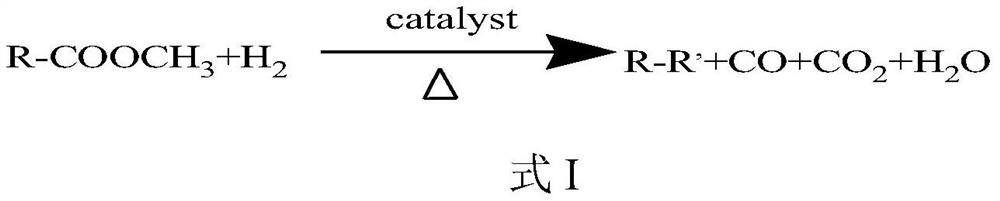

A biodiesel and deoxygenation reaction technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, carbon compound catalyst, liquid hydrocarbon mixture preparation, etc., can solve the problem of low utilization rate and catalytic efficiency, low H atom economy , Carrier acid center residues and other issues, to achieve high metal utilization, improve product selectivity, and improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] catalyst preparation

[0038] (1) Preparation of catalyst carrier. Weigh 60.294g Al (NO 3 ) 3 ·9H 2 O (molecular weight: 375), 0.630g Mn (NO 3 ) 2 (Molecular weight: 179) and 2.559g Ba (NO 3 ) 2 (Molecular weight: 261) was dissolved in 150ml of deionized water, made into a solution, and stirred for 1 h; heated the solution to 60°C, neutralized with 5wt% sodium carbonate solution, and controlled the pH to 9; filtered and washed with deionized water and then used 10mol / L nitric acid solution was acidified to pH 6, stirred to a sol-like state to obtain a carrier slurry; the slurry was added dropwise to the oil-ammonia column, the sol was shrunk into a spherical gel, aged for 2 hours, the gel spheres were taken out, and washed with deionized water , dried at 120 °C for 12 h, and calcined at 500 °C for 8 h to obtain composite oxide carrier beads;

[0039] (2) Weigh 0.057g SnCl 2 ·2H 2 O (molecular weight: 226) and 0.120 g H 2 PtCl 6 ·6H 2 O (molecular weight: 5...

Embodiment 2

[0043] The catalyst preparation process is the same as that of Example 1.

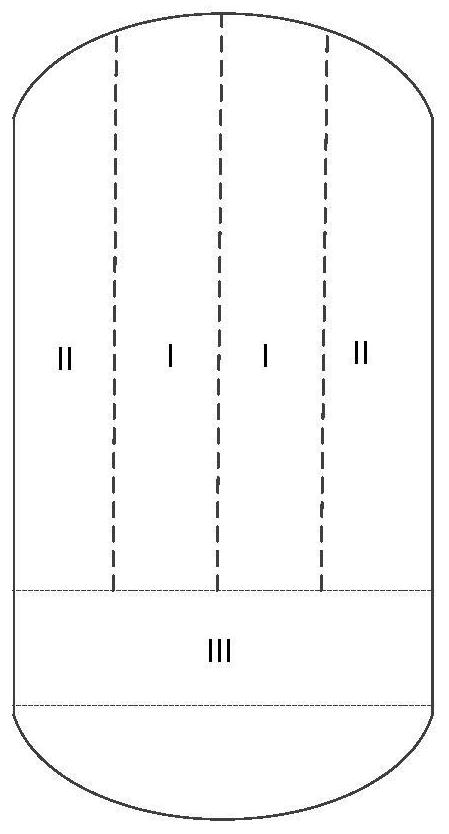

[0044] Catalyst evaluation: The evaluation conditions were the same as in Example 1, except that the evaluation raw material was changed to methyl oleate. The specific conditions are that the reactor adopts a radial reactor, and the reaction temperature of hydrogenation bed I (loaded with basic alumina, Shanghai Yuanjiang Chemical, 80-160 mesh) and hydrogenation bed II (loaded with catalyst A) is 45 ° C, The reaction pressure was 4.0MPa, the molar ratio of hydrogen and methyl oleate (18:1) was 0.5, and the liquid hourly space velocity was 4h -1 . The catalyst needs to be reduced with pure hydrogen before the reaction. The reduction temperature is 500°C and the reduction time is 3h. The catalyst for cracking bed III is selected as ZSM-5 type catalytic material, and the process conditions are 600 ℃ and space velocity 10h -1 , the reaction pressure is 4.0MPa, and the catalyst-oil ratio is 8. The cataly...

Embodiment 3

[0046] (1) Preparation of catalyst carrier. Weigh 57.904g Al (NO 3 ) 3 9H2O (molecular weight: 375), 0.756g Mn (NO 3 ) 2 (Molecular weight: 179) and 3.071g Ba (NO 3 ) 2 (Molecular weight: 261) was dissolved in 150ml of deionized water, made into a solution, and stirred for 1 hour; heated the solution to 45°C, neutralized with 5wt% sodium carbonate solution, and controlled the pH to 9; filtered and washed with deionized water and then used 10mol / L nitric acid solution was acidified to pH 6, stirred to a sol-like state to obtain a carrier slurry; the slurry was added dropwise to the oil-ammonia column, the sol was shrunk into a spherical gel, aged for 2 hours, the gel spheres were taken out, and washed with deionized water , dried at 160°C for 18h, and calcined at 550°C for 8h to obtain composite oxide carrier pellets;

[0047] (2) Weigh 0.028g SnCl 2 ·2H 2 O (molecular weight: 226) and 0.060 g H 2 PtCl 6 ·6H 2 O (molecular weight: 518) was dissolved in 250 ml of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com