Moisture-curable polyurethane hot melt adhesive for acoustic elements and preparation method

A polyurethane hot-melt adhesive and acoustic component technology, applied in the field of polyurethane hot-melt adhesive, can solve the problems affecting the performance of acoustic components and high VOC content, achieve high final curing strength, low organic volatile content, and improve the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

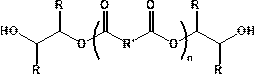

Method used

Image

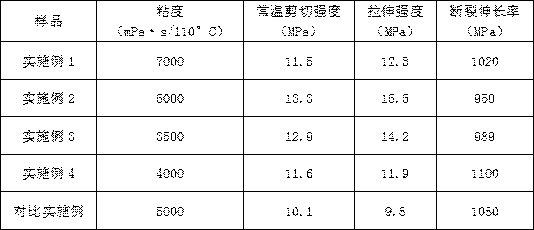

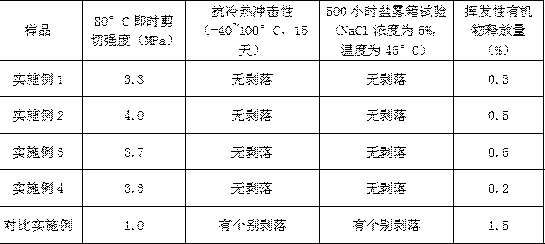

Examples

Embodiment 1

[0030] 1) Put 25 parts of adipic acid-1,4-butanediol (PBA-2000), 30 parts of polyoxypropylene glycol (PPG-2000), and 20 parts of C5 petroleum resin (Tg is 100°C) into In the reaction kettle, heat to 140°C under a vacuum of 0.1 MPa, stir at a speed of 500 rpm, and vacuum dehydrate for 2 hours;

[0031] 2) Cool down to 95°C, add 20 parts of diphenylmethane diisocyanate (MDI), stir at 800 rpm, raise the temperature to 120°C and keep it warm for 1 hour, then add 1 part of N-phenyl-γ - Aminopropyltrimethoxysilane, 0.05 parts of dimorpholino diethyl ether, heat preservation reaction for 1h under a vacuum of 0.1MPa;

[0032] 3) Add 4 parts of toluenesulfonyl hydrazide isocyanate, keep it warm for 1 hour under a vacuum of 0.1MPa, pour out the product under the protection of nitrogen gas, and seal the package to obtain a moisture-curing polyurethane hot-melt adhesive for acoustic components .

Embodiment 2

[0034] 1) Mix 30 parts of adipic acid-1,4-hexanediol (PHA-3000), 25 parts of polyethylene oxide glycol (PEG-2000), 15 parts of rosin resin (Tg is 80 ° C, acid value 10mgKOH / g) into the reaction kettle, heated to 130°C under a vacuum of 0.1MPa, stirred at a speed of 500 rpm, and vacuum dehydrated for 2 hours;

[0035] 2) Cool down to 95°C, add 25 parts of toluene diisocyanate (TDI), stir at 800 rpm, raise the temperature to 110°C and keep it warm for 1.5 hours, then add 1.5 parts of mercaptopropyltriethoxysilane , 0.08 parts of dimorpholino diethyl ether, insulated and reacted for 1h under a vacuum of 0.1MPa;

[0036] 3) Add 8 parts of triethyl orthoformate, heat-preserve and react for 1.5 hours under a vacuum of 0.1 MPa, pour out the product under the protection of nitrogen gas, and seal the package to obtain a moisture-curing polyurethane hot-melt adhesive for acoustic components.

Embodiment 3

[0038] 1) Mix 15 parts of adipate-1,4-hexanediol (PHA-3500), 15 parts of adipate-1,4-butanediol (PBA-2000), 25 parts of polyoxypropylene diol Alcohol (PPG-2000), 5 parts of C5 petroleum resin (Tg is 90°C), 10 parts of rosin resin (Tg is 90°C, acid value 8mgKOH / g) are put into the reaction kettle, and heated under a vacuum of 0.1MPa to 130°C, stir at a speed of 700 rpm, and vacuum dehydrate for 3 hours;

[0039] 2) Cool down to 100°C, add 5 parts of toluene diisocyanate (TDI) and 20 parts of diphenylmethane diisocyanate (MDI), stir at 900 rpm, heat up to 110°C for 1.5 hours, then Add 1.5 parts of mercaptopropyltriethoxysilane and 0.08 parts of dimorpholino diethyl ether, and keep the reaction for 1h under a vacuum of 0.1MPa;

[0040] 3) Add 5 parts of an oxazolidine compound, keep it under a vacuum of 0.1MPa for 1 hour, pour out the product under the protection of nitrogen gas, and seal the package to obtain a moisture-curing polyurethane hot-melt adhesive for acoustic compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com