Sound-absorbing material, preparation method thereof and loudspeaker using sound-absorbing material

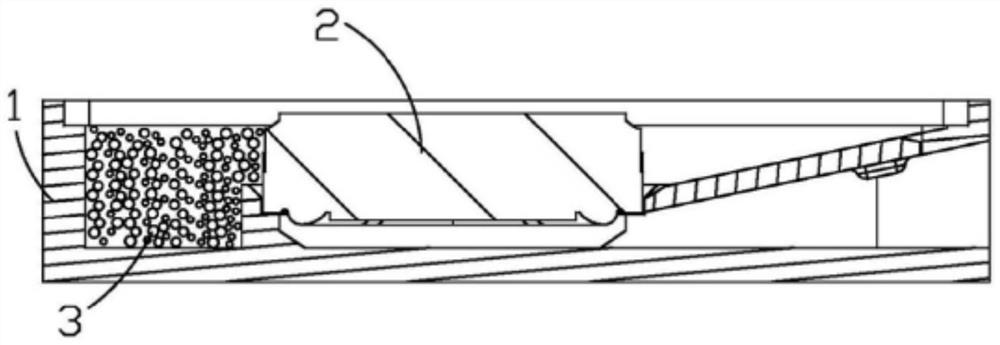

A technology of sound-absorbing materials and adsorption materials, applied in the field of loudspeakers, can solve the problems of loss of acoustic properties of sound-absorbing materials, unfavorable thermal conductivity of sound-absorbing materials, and excessive volume occupied by heat-conducting materials, and achieve small acoustic performance, excellent thermal conductivity, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

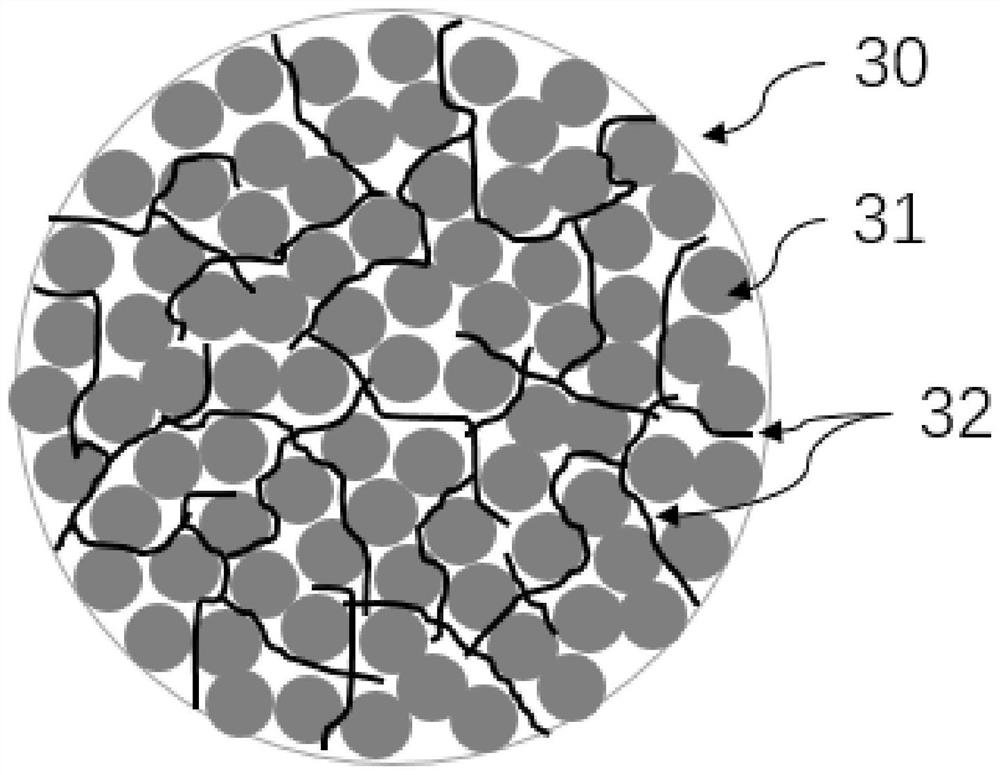

[0056] Preparation method One includes the following steps:

[0057] S1-1, dispersing the adsorbent material to the heat conductive material into the solvent, and mixed with a mixed solution containing the adsorbent material and the thermally conductive material; wherein the solvent can employ at least one in water, ethanol, and acetone.

[0058] S1-2, adding adhesives in a mixed solution containing an adsorbent material and a thermally conductive material, and mixing a slurry containing an adsorbent material and a heat conductive material;

[0059] S1-3, slurry containing adsorbent materials and thermally conductive materials to obtain product particles by granulation processes;

[0060] S1-4, product particles heat treatment to obtain a sound absorbing material.

[0061] The preparation method includes the following steps:

[0062] S2-1, dispersing the adsorbent material into the solvent, and mixing uniformly obtaining a mixed solution containing the adsorbent material;

[0063]...

Embodiment 1

[0074] The sound absorbing material was prepared by the preparation method, as follows:

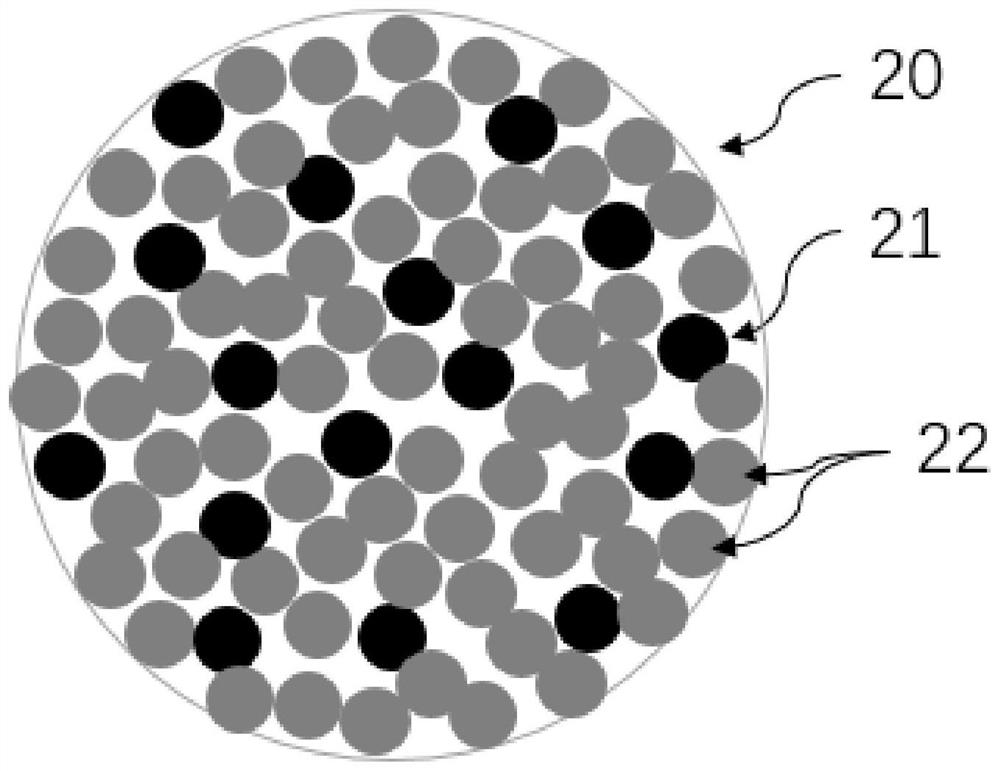

[0075] The adsorbent material is dispersed from the thermally conductive material into the solvent, and mixed with the adsorbent material and the thermally conductive material is mixed by stirring. Among them, the adsorbent material uses a MEL molecular sieve, and the thermally conductive material is used for nanocarbon fiber material, and the diameter of the nanocarbon fiber material is 150 nm to 200 nm, and the ratio of the length and diameter of the nanocarbon fiber material is 70, the solvent is water.

[0076] The adhesive is added to the mixed solution containing the adsorption material and the thermally conductive material, and uniformly obtains the slurry containing the adsorbent material and the thermally conductive material by stirring. Among them, adhesive uses polyacrylic acid adhesive.

[0077] The slurry containing the adsorption material and the heat conductive material obtains...

Embodiment 2

[0081] The sound absorbing material was prepared by the preparation method, as follows:

[0082] The adsorbent material is dispersed from the thermally conductive material into the solvent, and mixed with the adsorbent material and the thermally conductive material is mixed by stirring. Among them, the adsorbent material uses a MEL molecular sieve, and the thermally conductive material is used for nanocarbon fiber material, and the diameter of the nanocarbon fiber material is 150 nm to 200 nm, and the ratio of the length and diameter of the nanocarbon fiber material is 70, the solvent is water.

[0083] The adhesive is added to the mixed solution containing the adsorption material and the thermally conductive material, and uniformly obtains the slurry containing the adsorbent material and the thermally conductive material by stirring. Among them, adhesive uses polyacrylic acid adhesive.

[0084] The slurry containing the adsorption material and the heat conductive material obtains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com