Preparation method of shielding layer of underwater acoustic transducer

A technology of underwater acoustic transducer and shielding layer, applied in the direction of sensors, electrical components, etc., can solve the problems of complex fixing method of shielding net and high requirements on the shape of the transducer, and achieve high reliability, little impact on acoustic performance, and shielding. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

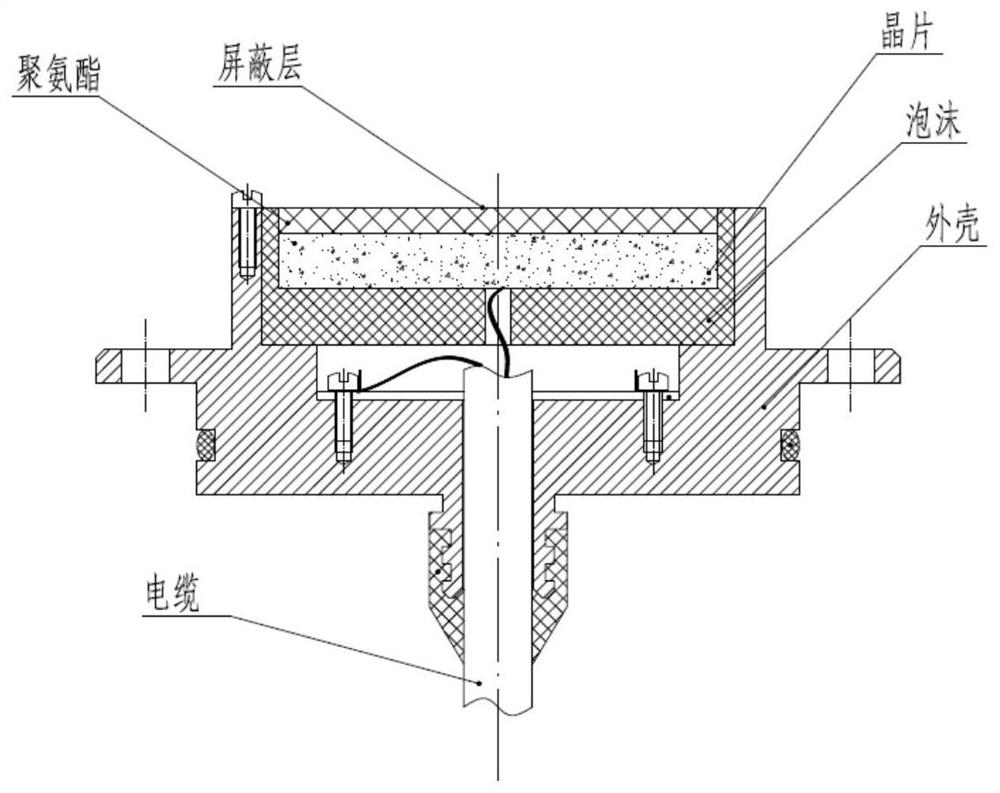

[0031] Such as Figure 4 As shown, the preparation method of the underwater acoustic transducer shielding layer provided by the present invention includes:

[0032] Step 1. Pouring a layer of polyurethane glue on the surface of the underwater acoustic transducer wafer, and curing it in an oven at 80°C;

[0033] Step 2. Install screws and soldering tabs on the metal shell, and lead a bare wire from the soldering tab on the metal shell of the transducer;

[0034] Step 3. Put the welded underwater acoustic transducer into the oven to preheat;

[0035] Step 4, using chemical reagents to treat the polyurethane on the surface of the preheated transducer;

[0036] Step 5. Apply a layer of conductive adhesive evenly on the surface of polyurethane, connect the conductive adhesive to the shell with bare wires, and put it in an oven to cure;

[0037] Step 6, performing surface treatment on the cured conductive adhesive layer;

[0038] Among them, the transducer potting polyurethane g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com