High-crystallinity polyphenylene sulfide composite material easy for machining shaping, preparation method and application thereof

A composite material and high crystallinity technology, applied in the field of high crystallinity polyphenylene sulfide composite material and its preparation, can solve the problems of incomplete crystallization and slow crystallization rate, achieve complete crystallization, increase crystallization temperature and crystallization rate, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

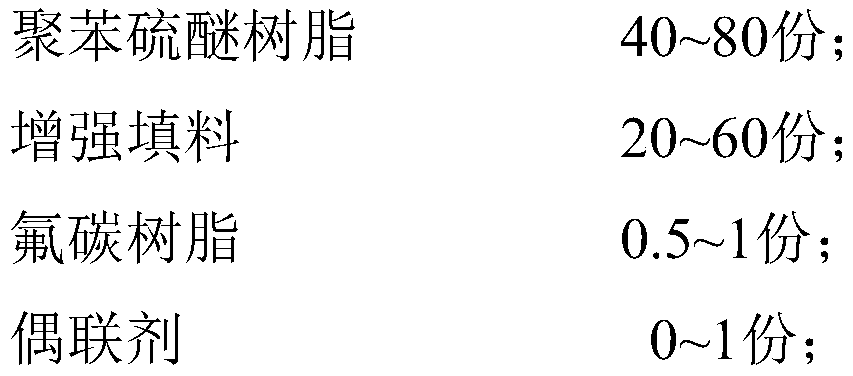

Method used

Image

Examples

Embodiment Construction

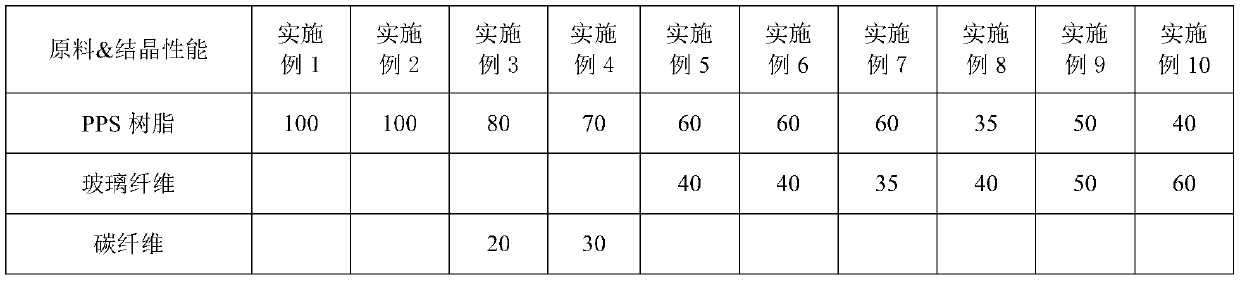

[0024] The following part is a specific implementation to further explain the present invention, but the following implementation is only a further explanation of the present invention, and does not mean that the protection scope of the present invention is limited to this, and all equivalent replacements based on the ideas of the present invention are included in this document. protection scope of the invention.

[0025] Embodiments of the invention employ the following raw materials:

[0026] PPS resin: Zhejiang NHU Co., Ltd., brand: 1150C;

[0027] Reinforcing filler 1: glass fiber, Chongqing International Composite Materials Co., Ltd., brand: ECS301HP-3;

[0028] Reinforcing filler 2: carbon fiber, Shanghai Jiufu New Material Technology Co., Ltd., brand: T700SC-12K;

[0029] Reinforcing filler 3: heavy calcium carbonate, Zhejiang Qintang Calcium Industry Co., Ltd., QT-8812 / 1250 mesh;

[0030] Fluorocarbon resin 1: polyvinylidene fluoride resin, Hubei Hongxin Ruiyu Fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com