Cellulose nanofiber-assisted nitrogen-doped carbon nanocage flexible film and preparation method thereof

A nanofiber and nitrogen-doped carbon technology, applied in the field of carbon nanomaterials, can solve the problems of insufficient electrical conductivity and electrochemical performance, and the inability to intercalate sodium, and achieve excellent electrochemical performance. The method is simple and easy, and is conducive to rapid The effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Firstly, 2g of 4MgCO3·Mg(OH)2·5H2O was placed in the center of the horizontal alumina tube of the tube furnace, and then flushed with high-purity N2, the gas flow rate was 40mL min-1, and the gas flushing time was 0.5h. Then the tube furnace was turned on at a rate of 5 °C min-1, the temperature was raised to 700 °C, and then acetonitrile was quickly introduced through the gas wash bottle so that acetonitrile gas was introduced into the furnace tube at a gas flow rate of 40 mL min-1. The holding time of the tube furnace is 3h, after which the acetonitrile is quickly removed, and the furnace is cooled to room temperature with the furnace to form carbon-coated MgO powder. Then, the prepared samples were thoroughly washed with 6M HCl solution to remove the MgO template, and repeatedly washed with deionized water and ethanol, and then freeze-dried for 24 h, and finally the samples were collected to obtain nitrogen-doped hierarchical carbon nanocages. Then the mechanically se...

Embodiment 2

[0038] The method of this example is basically the same as that of Example 1, except that the temperature of the tube furnace is raised to 800° C. during the preparation of the carbon nanocage.

Embodiment 3

[0040] The method of this example is basically the same as that of Example 1, except that the temperature of the tube furnace is raised to 900° C. during the preparation of the carbon nanocage.

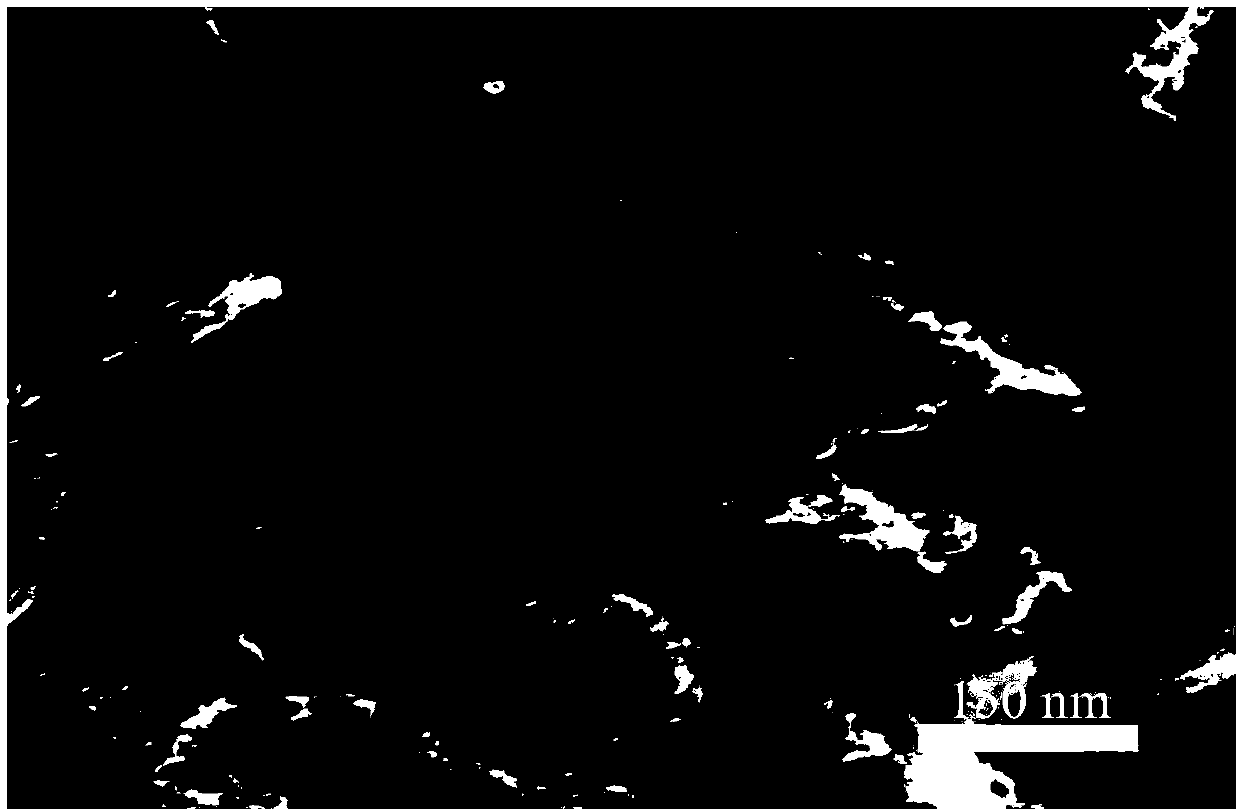

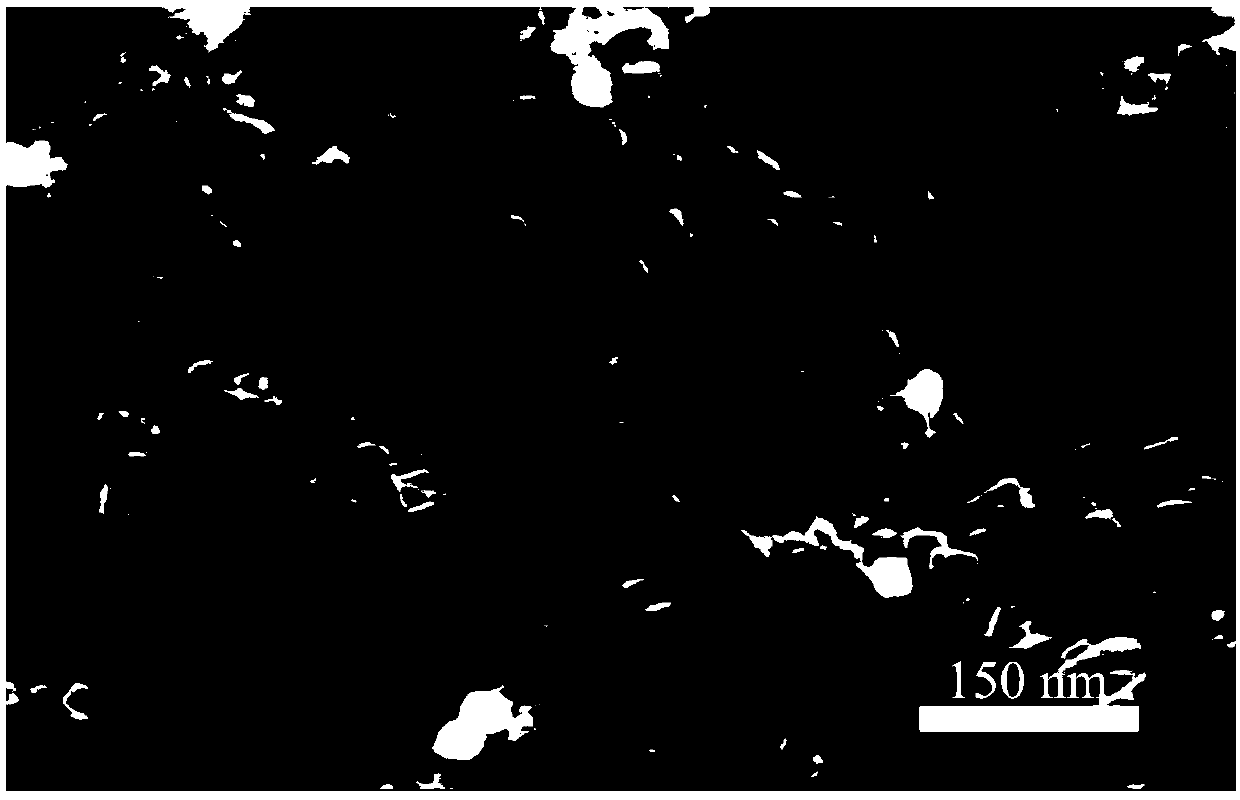

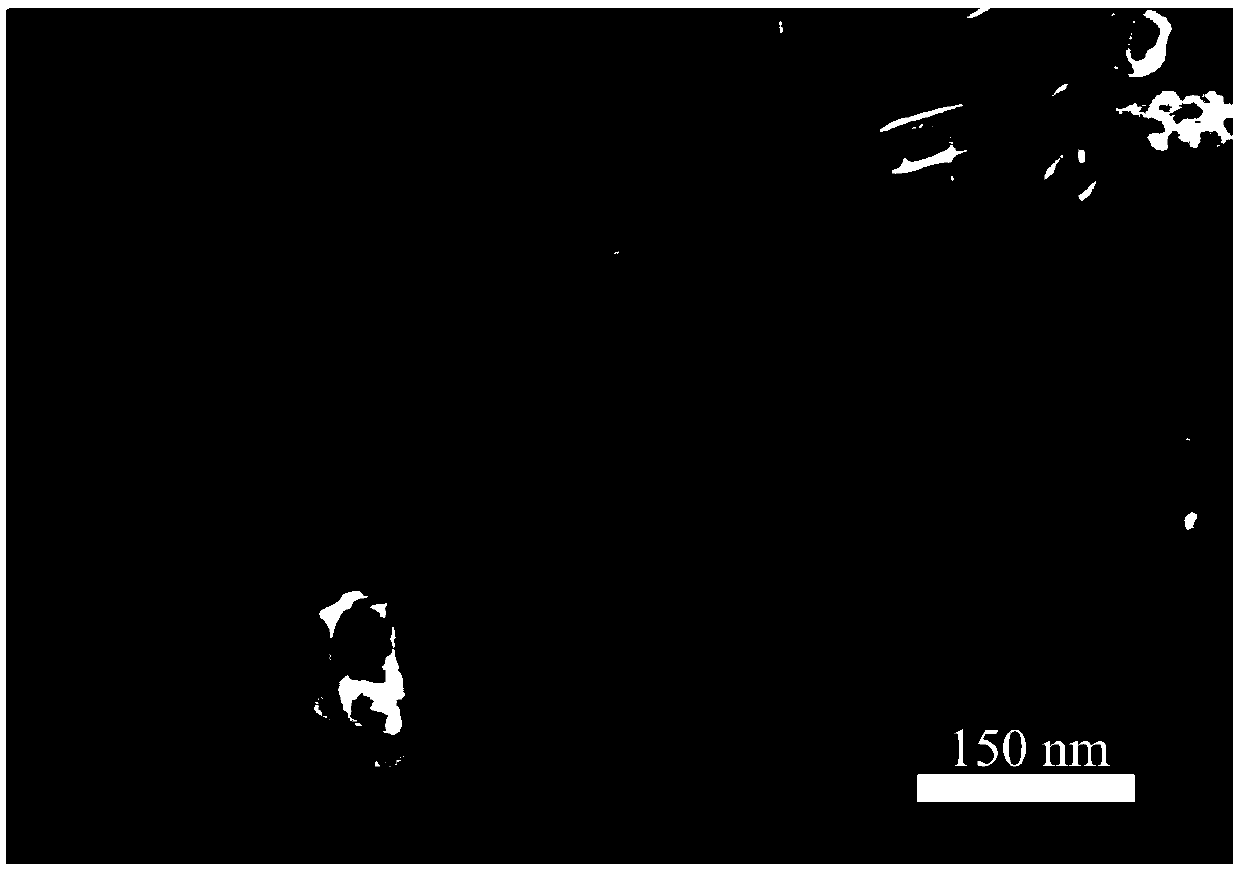

[0041] Figure 1-Figure 3 It is the SEM picture of the prepared carbon nanocage of embodiment 1-3, as can be seen from the figure when temperature is 700 ℃ (embodiment 1) carbon nanocage formation is irregular; When temperature rises to 800 °C (Example 2), regular carbon nanocages are formed, and the average size range of the carbon nanocages is 25-45nm. There are more gaps between the carbon nanocages, which can provide more active sites or defects for sodium ion storage and ensure excellent electrochemical performance. But when the temperature rises to 900°C (Example 3), the carbon nanocages will be seriously packed, which greatly reduces the pore volume of the material, which is not conducive to the insertion and extraction of sodium ions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com