Nano-bracelet ferric oxide/graphene quantum dot/stannic oxide core-shell structure composite material, preparation method thereof, and battery application of same

A graphene quantum dot, ferric oxide technology, applied in the direction of iron oxide/iron hydroxide, tin oxide, iron oxide, etc., can solve the problems of poor cycle performance, inability to adapt to demand, loss of active materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

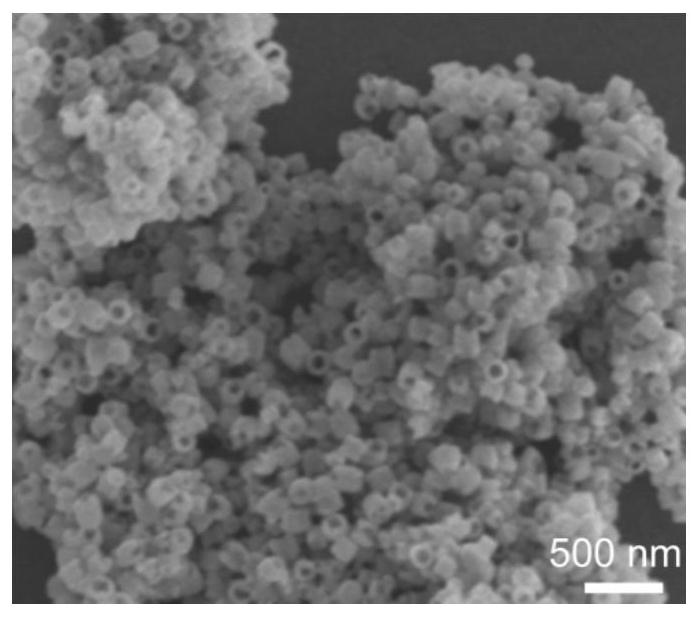

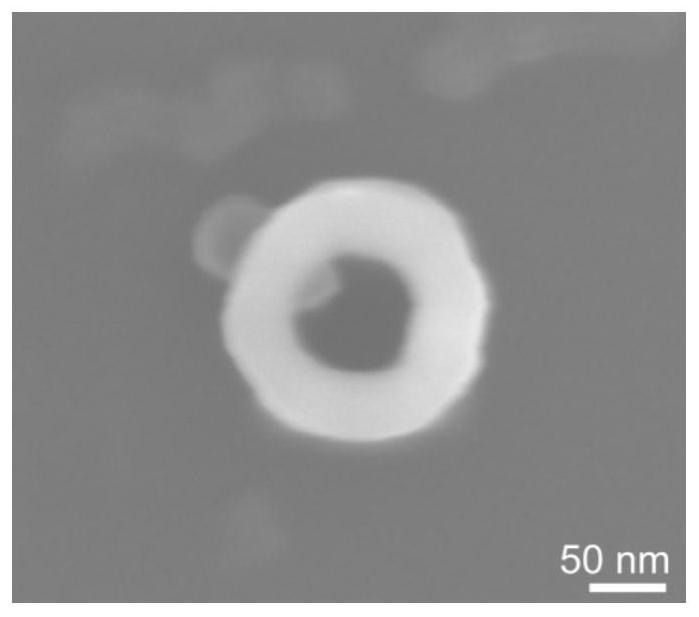

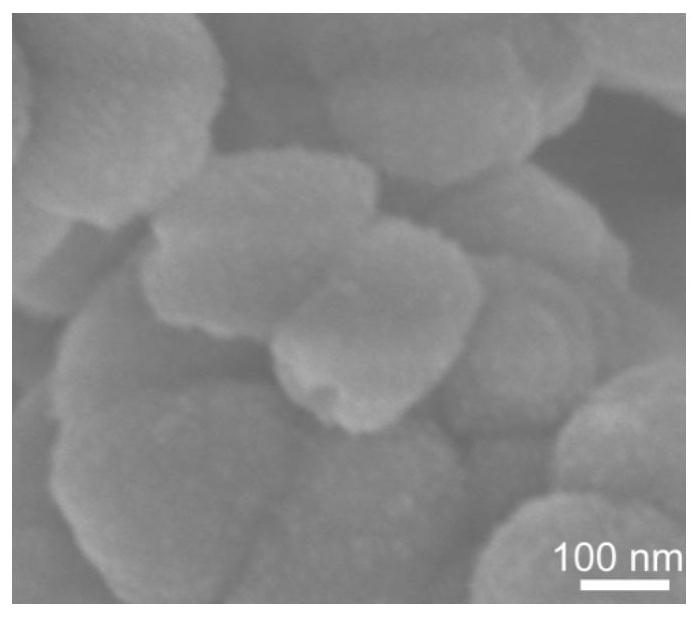

[0054] The preparation method of nano-bracelet ferric oxide / graphene quantum dot / tin dioxide core-shell structure composite material comprises the following steps:

[0055] 1) Add 0.35g of ferric chloride to 35ml of deionized water, then add 0.002g of sodium sulfate and 0.001g of sodium dihydrogen phosphate, mix and stir evenly, then transfer the solution to a polytetrafluoroethylene liner for hydrothermal reaction, set Set the temperature at 170°C and maintain it for 24 hours. After cooling to room temperature, wash and dry to obtain ferric oxide nano bracelet;

[0056] 2) Disperse 0.12g of ferric oxide nano-bracelet obtained in step 1) in 28ml of water, then add 6ml, 1mg / ml concentration of commercial graphene quantum dot solution, ultrasonically until the solution is uniform, transfer the solution to polytetrafluoroethylene The gallbladder was subjected to hydrothermal reaction, set the temperature at 160°C, and maintained for 8 hours. After the solution was cooled, it was ...

Embodiment 2

[0060] The preparation method of nano-bracelet ferric oxide / graphene quantum dot / tin dioxide core-shell structure composite material comprises the following steps:

[0061] 1) Add 0.25g of ferric chloride, 0.0026g of sodium sulfate, and 0.00125g of sodium dihydrogen phosphate into 30ml of deionized water, mix and stir evenly, then transfer the solution to a polytetrafluoroethylene liner for hydrothermal reaction, set the temperature Keep at 180°C for 28 hours, after cooling to room temperature, wash and dry to obtain ferric oxide nano bracelet;

[0062] 2) Disperse 0.15 g of ferric oxide nano-bracelet obtained in step 1) in 30 ml of water, then add 8 ml of a commercial graphene quantum dot solution with a concentration of 1 mg / ml, sonicate until the solution is uniform, and transfer the solution to polytetrafluoroethylene The gallbladder undergoes hydrothermal reaction, set the temperature at 180°C, and maintain it for 10 hours. After the solution is cooled, it is centrifuged ...

Embodiment 3

[0066] The preparation method of nano-bracelet ferric oxide / graphene quantum dot / tin dioxide core-shell structure composite material comprises the following steps:

[0067] 1) Add 0.26g of ferric chloride, 0.00345g of sodium sulfate, and 0.00125g of sodium dihydrogen phosphate into 40ml of deionized water, mix and stir evenly, then transfer the solution to a polytetrafluoroethylene liner for hydrothermal reaction, set the temperature Keep at 180°C for 36 hours, after cooling to room temperature, wash and dry to obtain ferric oxide nano bracelet;

[0068] 2) Dissolve 0.15 g of ferric oxide nano-bracelet obtained in step 1) in 32 ml of water, then add 6 ml of a commercial graphene quantum dot solution with a concentration of 1 mg / ml, sonicate until the solution is uniform, and transfer the solution to polytetrafluoroethylene The liner undergoes hydrothermal reaction, set the temperature at 180°C, and maintain it for 10 hours. After the solution is cooled, it is centrifuged and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com