Preparation of SnO2-NiO nanotube with hollow structure and application of SnO2-NiO nanotube in supercapacitor

A technology of sno2-nio and nanotubes, applied in the field of nanomaterials, can solve problems such as environmental pollution and operational safety impact, cumbersome operation and preparation, unfavorable large-scale actual production, etc., achieve excellent electrochemical activity, alleviate volume change, and multi-charge Storage of active site effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

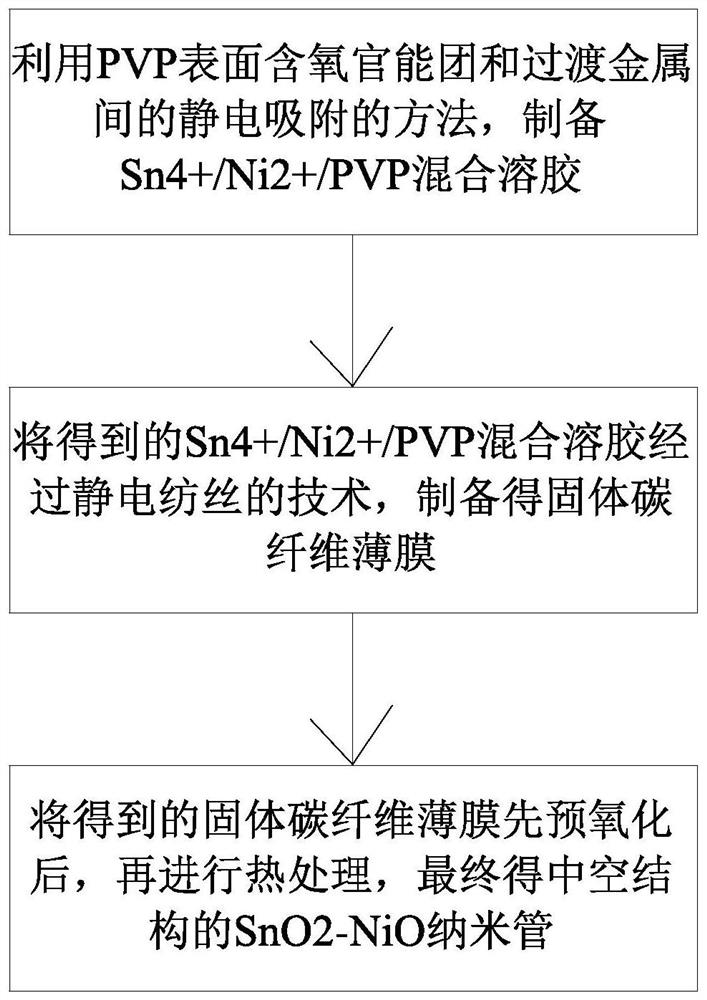

[0035] A hollow structure of SnO 2 -The preparation method of NiO nanotube, its specific preparation steps are as follows:

[0036] 1), weigh 1.0g PVP, 6ml DMF and 6ml C 2 h 5 OH solution mixed, add 1.0mmol of SnCl 4 With 1.0mmol Ni(NO 3 ) 2 ·6H 2 O solid metal salt; after mechanical stirring at room temperature for 12h to mix evenly, light green Sn 4+ / Ni 2+ / PVP sol;

[0037] 2), the light green Sn prepared in step 1) 4+ / Ni 2+ / PVP sol, processed by electrospinning technology, the spinning temperature is controlled at 25°C, and the injection speed is 1.0mL·h -1 , voltage 22KV, the solid carbon fiber film material obtained, first undergoes pre-oxidation treatment in the air at 200°C for 3h, and then heats up to 500°C at a heating rate of 5°C / min in the air atmosphere for heat treatment, and at this temperature Keep for 3h, then cool to room temperature to get the final product.

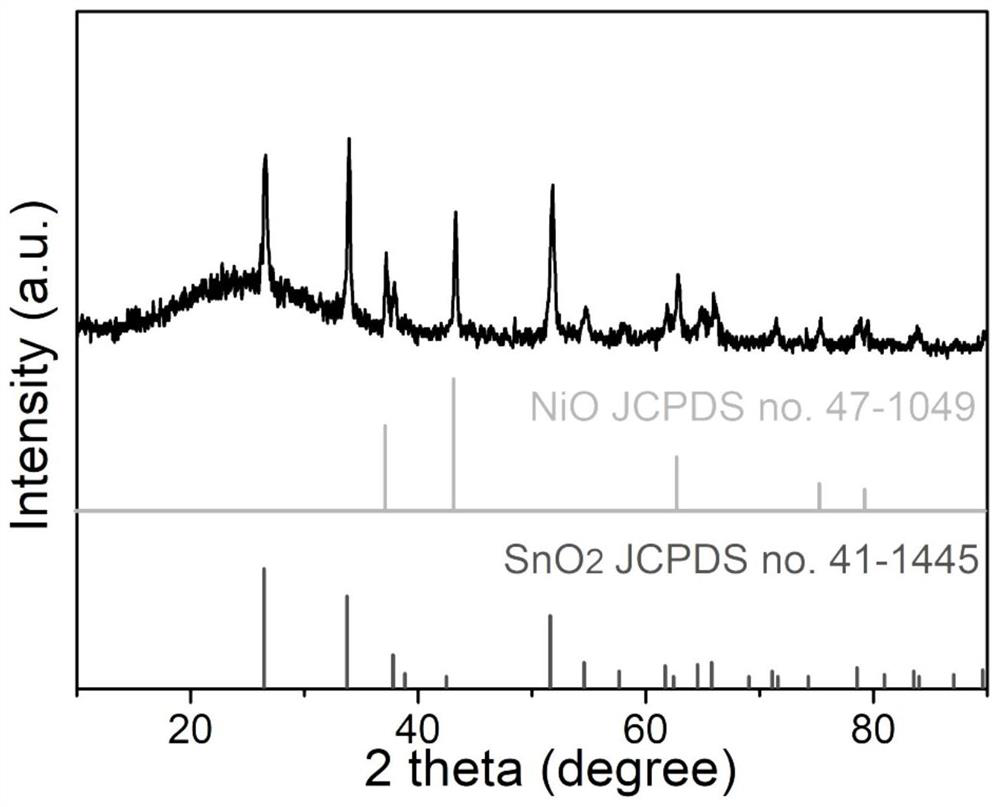

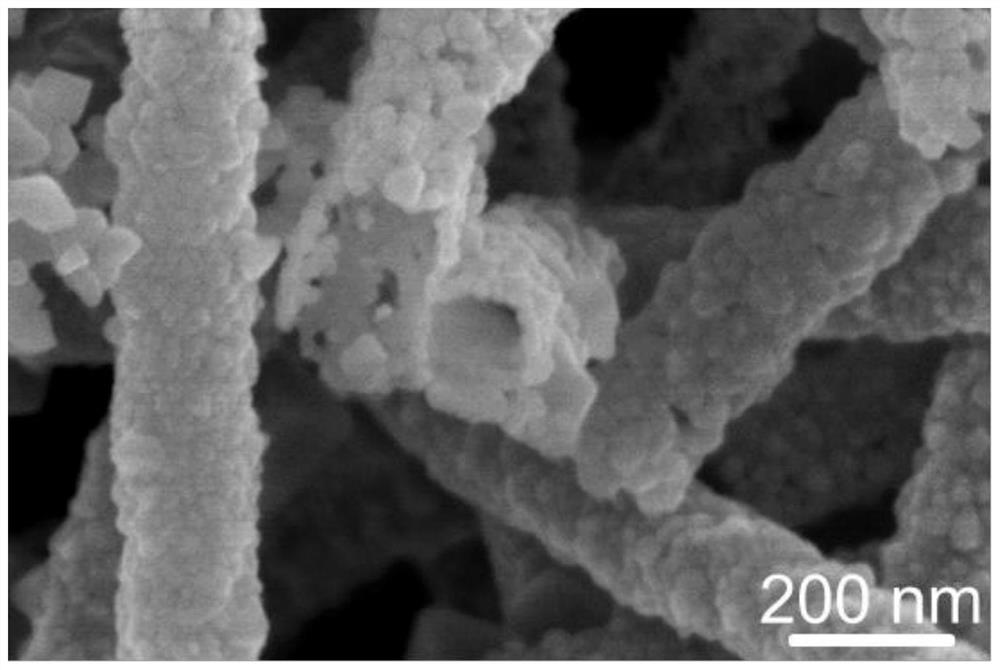

[0038] Adopt TEM, SEM and XRD etc. to the SnO of the hollow structure that above emb...

Embodiment 2

[0040] A hollow structure of SnO 2 -The preparation method of NiO nanotube, its specific preparation steps are as follows:

[0041] 1), weigh 1.0g PVP, 6ml DMF and 6ml C 2 h 5 OH solution mixed, add 1.0mmol of SnCl 4 with 0.5mmol Ni(NO 3 ) 2 ·6H 2 O solid metal salt; after mechanical stirring at room temperature for 12h to mix evenly, light green Sn 4+ / Ni 2+ / PVP sol;

[0042] 2), the light green Sn prepared in step 1) 4+ / Ni 2+ / PVP sol, processed by electrospinning technology, the spinning temperature is controlled at 25°C, and the injection speed is 1.0mL·h -1 , voltage 22KV, the solid carbon fiber film material obtained, first undergoes pre-oxidation treatment in the air at 200 °C for 3 hours, and then heats up to 500 °C at a heating rate of 5 °C / min in the air atmosphere for heat treatment, and at this temperature Keep for 3h, then cool to room temperature to get the final product.

Embodiment 3

[0044] A hollow structure of SnO 2 -The preparation method of NiO nanotube, its specific preparation steps are as follows:

[0045] 1), weigh 1.0g PVP, 6ml DMF and 6ml C 2 h 5 OH solution mixed, add 0.5mmol of SnCl 4 With 1.0mmol Ni(NO 3 ) 2 ·6H 2 O solid metal salt; after mechanical stirring at room temperature for 12h to mix evenly, light green Sn 4+ / Ni 2+ / PVP sol;

[0046] 2), the light green Sn prepared in step 1) 4+ / Ni 2+ / PVP sol, processed by electrospinning technology, the spinning temperature is controlled at 25°C, and the injection speed is 1.0mL·h -1 , voltage 22KV, the solid carbon fiber film material obtained, first undergoes pre-oxidation treatment in the air at 200 °C for 3 hours, and then heats up to 500 °C at a heating rate of 5 °C / min in the air atmosphere for heat treatment, and at this temperature Keep for 3h, then cool to room temperature to get the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com