Boron-doped diamond/graphite composite electrode, preparation method, and double-cell reactor

A boron-doped diamond and composite electrode technology, which is applied in the field of new functional thin film materials, can solve problems such as large differences in thermal expansion coefficients, damage to normal use of equipment, and easy to contaminate chambers, etc., to improve the bonding force of the film base, strengthen the mechanical lock and The effect of improving the binding force of the membrane base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

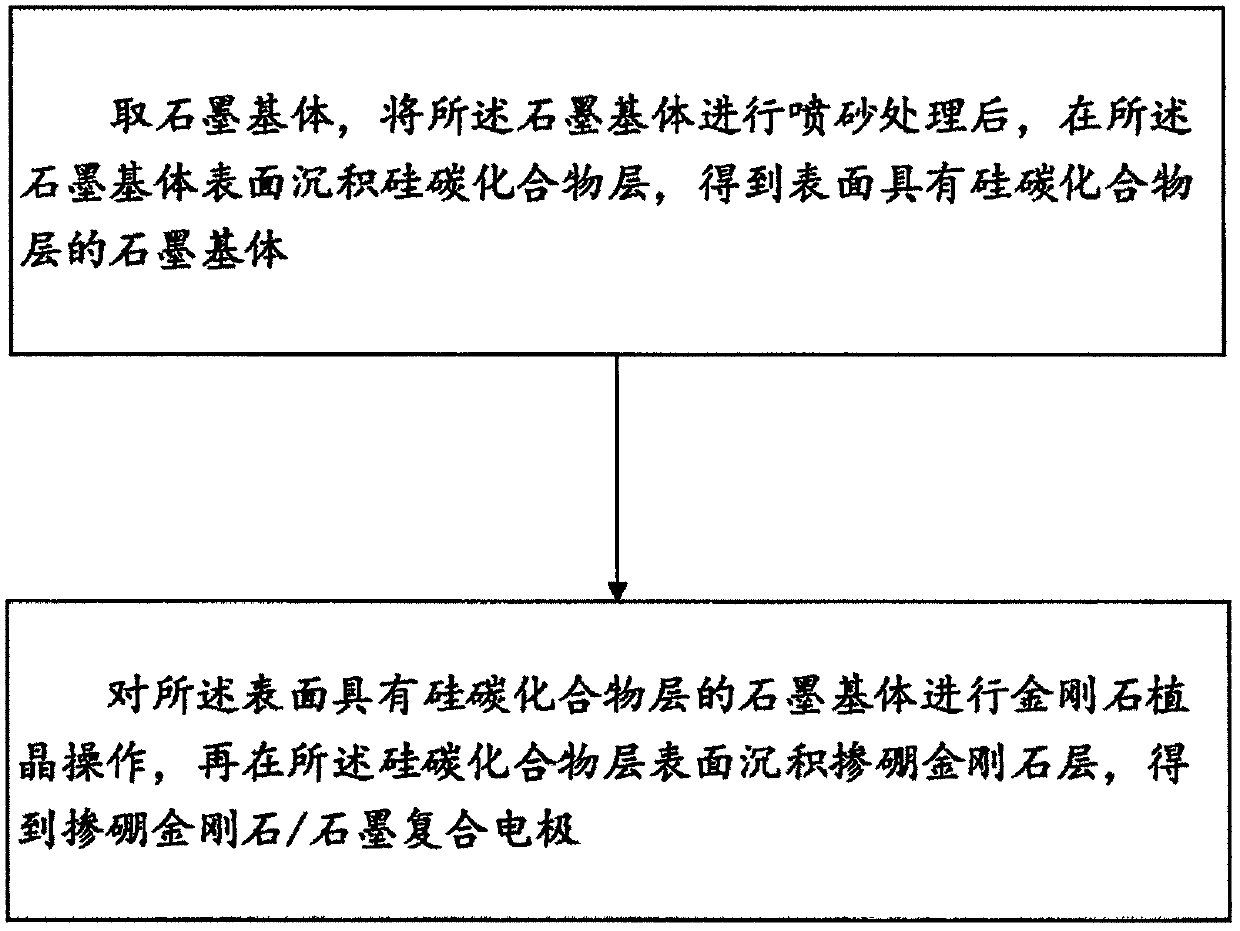

[0030] Please refer to figure 2 , a method for preparing a boron-doped diamond / graphite composite electrode provided in an embodiment of the present invention, comprising the following steps:

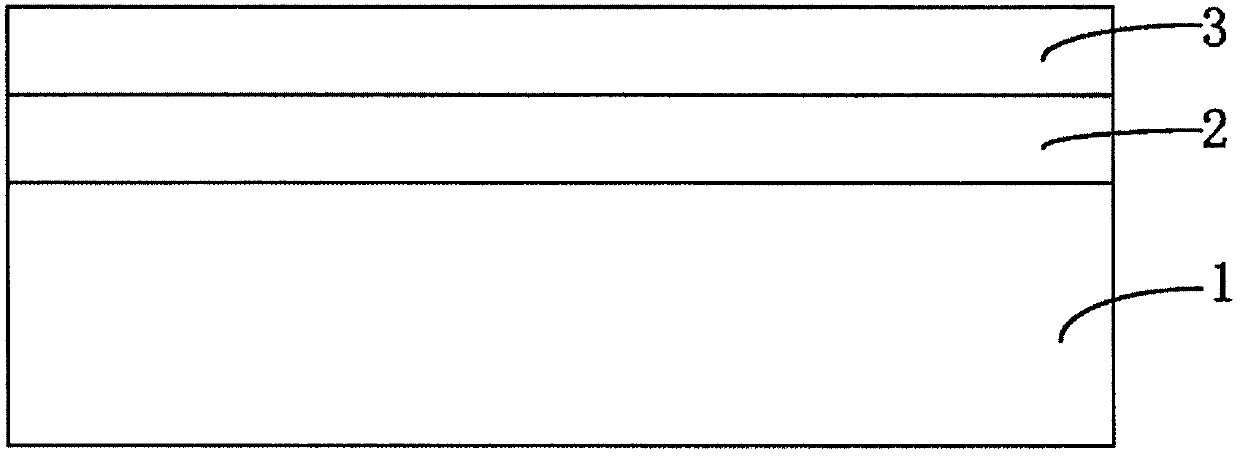

[0031] Step 1: Take the graphite substrate 1, and after sandblasting the graphite substrate 1, deposit a silicon-carbon compound layer 2 on the surface of the graphite substrate 1 to obtain a graphite substrate 1 with a silicon-carbon compound layer 2 on the surface;

[0032] Step 2: Carry out a diamond planting operation on the graphite substrate 1 with a silicon carbide layer 2 on the surface, and then deposit a boron-doped diamond layer 3 on the surface of the silicon carbide layer 2 to obtain a boron-doped diamond / graphite composite electrode.

[0033]In the preparation method provided by the embodiment of the present invention, firstly, the surface of the electrode is roughened by sandblasting pretreatment, which further enhances the mechanical lock and effect between the graphite...

Embodiment 1

[0044] A preparation method of boron-doped diamond / graphite composite electrode, comprising the following steps:

[0045] Step 1: Take the graphite substrate, place the graphite substrate in a sandblasting machine for wet sandblasting. Among them, the sand particles are silicon carbide, the particle size of the sand particles is 50μm, the pressure of the spray gun is 2bar, and the sandblasting is until the surface is rough, and finally Rinse with deionized water and blow dry with nitrogen.

[0046] The silicon carbide layer is deposited on the surface of the sandblasted graphite substrate by magnetron sputtering. During the deposition process, the graphite substrate is firstly cleaned by glow cleaning and ion etching. Among them, the specific operation of the glow cleaning is as follows: argon gas with a flow rate of 300 sccm is introduced, the negative bias voltage of the graphite substrate is 500 V, the cleaning pressure is 1.0 Pa, and the cleaning time is 30 minutes. The s...

Embodiment 2

[0050] A preparation method of boron-doped diamond / graphite composite electrode, comprising the following steps:

[0051] Step 1: Take the graphite substrate, place the graphite substrate in a sandblasting machine for wet sandblasting. Wherein, the sand particles are aluminum oxide, the particle size of the sand particles is 100 μm, the pressure of the spray gun is 4 bar, and the sand is blasted until the surface is rough, and finally cleaned with deionized water and dried with nitrogen. The silicon carbide layer is deposited on the surface of the sandblasted graphite substrate by magnetron sputtering. During the deposition process, the graphite substrate is firstly cleaned by glow cleaning and ion etching. Among them, the specific operation of glow cleaning is: argon gas with a flow rate of 500 sccm is introduced, the negative bias voltage of the graphite substrate is 800 V, the cleaning pressure is 1.7 Pa, and the cleaning time is 10 minutes. The specific operation of ion e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com