90-DEG C low-shrinkage ultraviolet-proof medium-density polyethylene sheath material and preparation method thereof

A density polyethylene, anti-ultraviolet technology, applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve problems such as safety accidents and quality accidents, high suspension voltage, grounding copper shell pull-off, etc. The effect of good appearance quality, excellent weather resistance and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

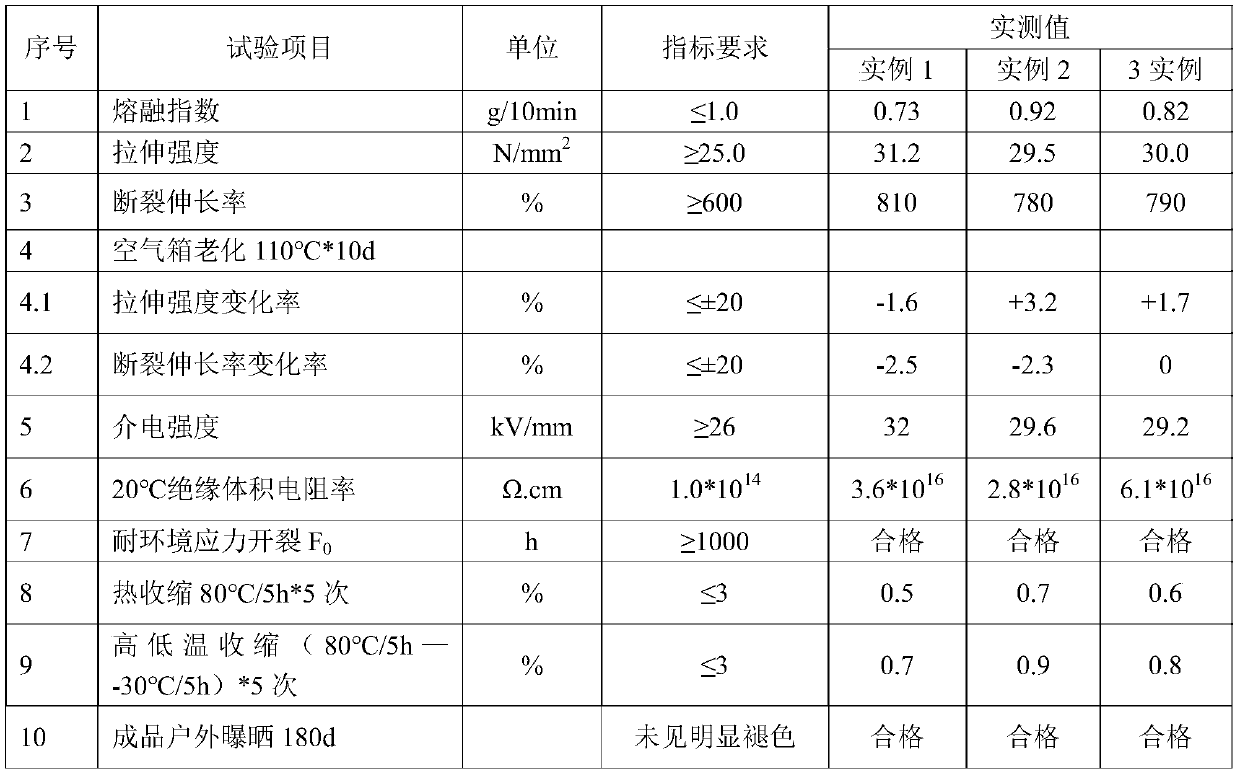

Examples

Embodiment 1

[0023] Formula: 40 parts of metallocene polyethylene (Exxon, 1327MA, pellets), 40 parts of bimodal polyethylene (Sabic, B5403, pellets), 20 parts of linear low-density polyethylene (Zhenhai Petrochemical, 7042, pellets), lubricated Agent (a mixture of polyethylene wax (Changzhou Kesaicheng, polyethylene wax 2420, powder) and zinc stearate with a mass ratio of 2:1) 1.8 parts, color masterbatch (Shanghai Wujiang new material, 50-RD-3245 , pellets) 1 part, 0.6 part of antioxidant (the mixture of antioxidant 1010 and antioxidant 168 mass ratio is 3:2), ultraviolet light stabilizer (benzotriazole type and benzophenone type mass ratio 5:4 mixture) 0.3 parts.

[0024] The sheath material is prepared according to the following steps: 1) Separately weigh the pellets and powder in the raw materials, mix them evenly, and then put them all into a plastic high-speed mixer to mix to obtain a mixture; 2) put the obtained mixture into Put it into the barrel of a twin-screw extruder, extrude ...

Embodiment 2

[0026] Formula: 30 parts of metallocene polyethylene (Exxon, 4009, pellets), 30 parts of bimodal polyethylene (Sabic, B5822, pellets), 40 parts of linear low-density polyethylene (Zhenhai Petrochemical, 7042, pellets), lubricated Agent (a mixture of polyethylene wax (Changzhou Kesaicheng, polyethylene wax 2420, powder) and zinc stearate with a mass ratio of 1:1) 1.6 parts, color masterbatch (Shanghai Wujiang new material, 50-RD-3245 , pellets) 1 part, 0.6 part of antioxidant (the mixture of antioxidant 1010 and antioxidant 168 mass ratio is 3:4), ultraviolet light stabilizer (benzotriazole type and benzophenone type mass ratio 5:3 mixture) 0.4 parts.

[0027] The preparation of the sheath material refers to Example 1.

Embodiment 3

[0029] Formula: 30 parts of metallocene polyethylene (Exxon, 3505, pellets), 40 parts of bimodal polyethylene (Sabic, 5822, pellets), 30 parts of linear low-density polyethylene (Sabic, 320NT, pellets), lubricant (a mixture of polyethylene wax (Changzhou Kesaicheng, polyethylene wax 2420, powder) and zinc stearate with a mass ratio of 1:1) 1.6 parts, color masterbatch (Shanghai Wujiang New Material, 50-RD-3245, Granules) 1 part, 0.8 part of antioxidant (the mixture of antioxidant 1010 and antioxidant 168 mass ratio is 3:4), ultraviolet light stabilizer (benzotriazole type and benzophenone type mass ratio 5 :3 mixture) 0.4 parts.

[0030] The preparation of the sheath material refers to Example 1.

[0031] The sheath material prepared in the above-mentioned embodiments is extruded through a single-screw extruder to produce cables of corresponding specifications. The specific production equipment and processes are as follows:

[0032] 1) Single-screw extruder model EXT-150-50D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com