A welding device, welding method and application for low melting point alloy

A welding device, low melting point technology, applied in welding/welding/cutting items, welding equipment, high-frequency current welding equipment, etc., can solve problems such as insignificant effects, avoid mechanical properties, and ensure consistency and uniformity , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

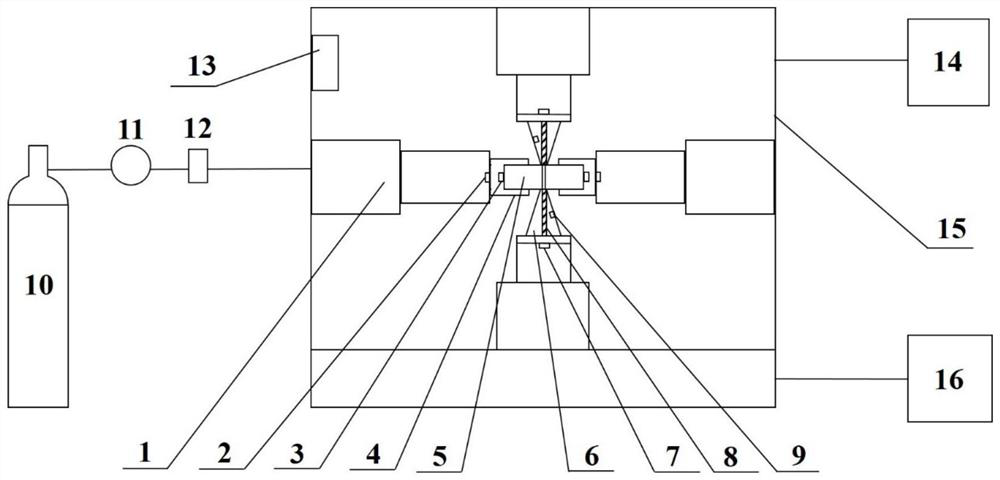

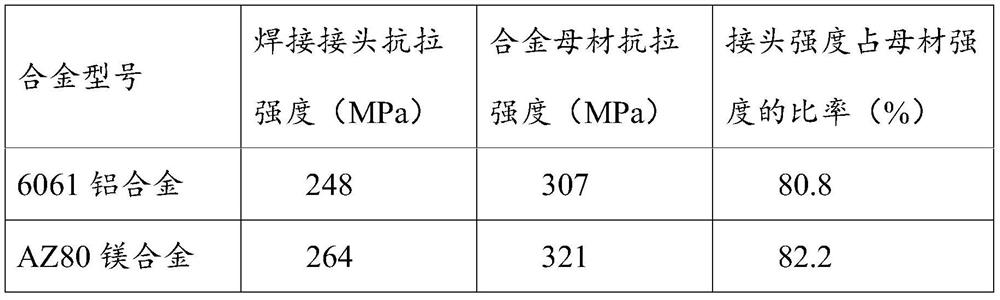

[0059] Use this device to weld 6061 aluminum alloy:

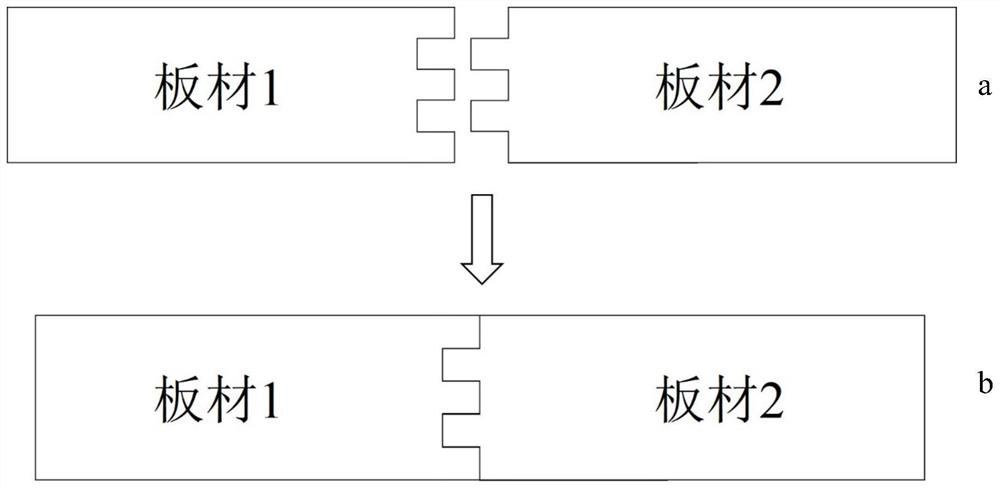

[0060] (1) The thickness of the 6061 aluminum alloy welded joint plate is 3mm, and the size is 110×60mm. First, the edge of the plate to be welded is processed into a step shape, and then the surface dirt is removed with sandpaper, and the surface grease is removed with acetone;

[0061] (2) Put the processed 6061 aluminum alloy sheet into an airtight container, use the horizontal squeeze chuck to adjust the size of the clamping block, wrap and clamp the sheet to be welded, and the two sheets are occluded and fastened;

[0062] (3) After the airtight box is evacuated, a certain amount of argon gas is filled to protect the 6061 aluminum alloy sheet to prevent high temperature oxidation of the welded sheet;

[0063] (4) For the telescopic contact heating block, conduct energized high-frequency heating to 900°C, then extend the upper and lower heating blocks to the upper and lower surfaces of the 6061 aluminum alloy plate, and...

Embodiment 2

[0068] Use this device to weld AZ80 magnesium alloy:

[0069] (1) The thickness of AZ80 magnesium alloy welded joint plates is 4mm, and the size is 120×50mm. Firstly, the edge of the plate to be welded is processed into a step shape, and then the surface dirt is removed with sandpaper, and the surface grease is removed with acetone;

[0070] (2) Put the processed AZ80 magnesium alloy plate into a closed container, use the horizontal squeeze chuck to adjust the size of the clamping block, cover and clamp the plate to be welded, and the two plates are occluded and fastened;

[0071] (3) After the airtight box is evacuated, a certain amount of argon gas is filled in, and the AZ80 magnesium alloy plate is protected by gas to prevent high-temperature oxidation of the welded plate;

[0072] (4) For the telescopic contact heating block, conduct high-frequency heating to 850°C, and then extend the upper and lower heating blocks to the upper and lower surfaces of the AZ80 magnesium all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com