Electrochemical method for accelerating dissolution of soluble bridge plug

An electrochemical and bridge plug technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the problems affecting the oil extraction time and construction progress, so as to speed up the dissolution rate and improve the operation efficiency , The effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

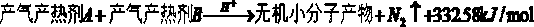

[0027] In order to overcome the existing problem that the bridge plug cannot be quickly dissolved, and the waiting time for the bridge plug to dissolve is too long, which affects the construction progress, the present invention provides such figure 1 and 2 An electrochemical method for accelerating the dissolution of soluble bridge plugs is shown. The present invention uses the electrochemical (primary battery and electrolytic cell) method to use the potential difference of various metals to quickly dissolve by giving a certain current on the casing. Soluble balls and soluble bridge plugs can restore wellbore diameter in time, which is of great practical significance for rapid production or rapid fracturing construction of the next stage.

[0028] An electrochemical method for accelerating the dissolution of soluble bridge plugs, the specific steps are: step 1, for the case where the inner wall of the casing has been internally protected against corrosion,

[0029] First with...

Embodiment 2

[0041] Based on Example 1, in this example, in step 1, the gas and heat generating agent A is composed of ammonium chloride and citric acid with a mass ratio of 15: (1-5), and the gas and heat generating agent A is composed of ammonium chloride and citric acid. The mass concentration of thermal agent A is 25-35%, and the injection volume of gas-generating and heat-generating agent A is 3-5m 3 .

[0042] In the described step one, the guar gum base liquid injection volume is 2-4m 3 .

[0043] In the described step 1, the gas-generating and heat-generating agent B is sodium nitrite, and its mass concentration is 45%-55%; the injection volume of the gas-generating and heat-generating agent B is 3-5m 3 .

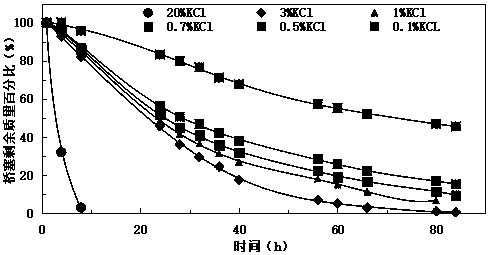

[0044] The saturated strong electrolyte in described step 1 and step 2 is potassium chloride, sodium chloride or calcium chloride, and saturated potassium chloride mass concentration is 34.2% at room temperature, and saturated sodium chloride mass concentration is 36.0%, satu...

Embodiment 3

[0066] Based on Examples 1 and 2, in this example, after staged multi-cluster volumetric fracturing with soluble bridge plugs in Well Hua H-X, it needs to be put into production quickly. After 3 days of shutting down, the bridge plugs are still not dissolved.

[0067] at 2m 3 / min displacement injection 5m 3 15% sulfuric acid, then connect 5m 3 Guar gum base fluid is used for isolation, and water is used to replace it to the position of the bridge plug. After about 1.5 hours, the bridge plug dissolves, and fluid comes out from the wellhead, leading to normal drainage and production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com