Preparation method of semi-aromatic polyamide

A semi-aromatic and polyamide technology, applied in the field of preparation of semi-aromatic polyamides, can solve the problems of difficult control of monomer ratio, incomplete reaction, difficult solid-liquid separation, etc., and achieves less harsh preparation conditions and avoids mixing. The effect of ratio imbalance and easy industrial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In this example, a semi-aromatic polyamide is actually prepared, and the steps include:

[0083] (1) Put 1344.6g (8.1mol) of terephthalic acid, 149.4g (0.9mol) of isophthalic acid, 1548g (9mol) of decanediamine, 5Kg of ethanol and 5kg of deionized water in a magnetically coupled stirring, condensing In a 20L autoclave with pipe, exhaust port and pressure explosion-proof port, heat up to 90°C and keep it warm for 30min;

[0084] (2) Control the temperature at 90°C, evaporate and collect the condensed ethanol, and the collected ethanol can be reused until no obvious fraction is distilled out;

[0085] (3) Add 24.4g (0.2mol) of benzoic acid and 8g of sodium hypophosphite and continue to heat up to 300°C. During this period, the water is slowly discharged, and the pressure is maintained at 2.5MPa, and then reduced to 0.6MPa, and the semi-aromatic is obtained by discharging. The polyamide prepolymer can be obtained after being crushed and increased in solid phase at 200°C f...

Embodiment 2

[0088] In this example, a semi-aromatic polyamide is actually prepared, and the steps include:

[0089] (1) Put 1660g (10mol) of terephthalic acid, 2043g (10.2mol) of dodecanediamine, 8Kg of ethanol and 4kg of deionized water in a place equipped with magnetic coupling stirring, condenser, exhaust port and pressure explosion-proof port In a 20L autoclave, heat up to 80°C and keep warm for 30min;

[0090] (2) Control the temperature at 90°C, evaporate and collect the condensed ethanol, and the collected ethanol can be reused until no obvious fraction is distilled out;

[0091] (3) Add 12.2g (0.1mol) of benzoic acid and 10g of sodium hypophosphite and continue to heat up to 310°C. During this period, the water is slowly discharged to maintain the pressure of 3.5MPa, and then the pressure is reduced to 0.6MPa, and the semi-aromatic poly The amide prepolymer can be obtained after being crushed and increased in solid phase at 240°C for 2 hours.

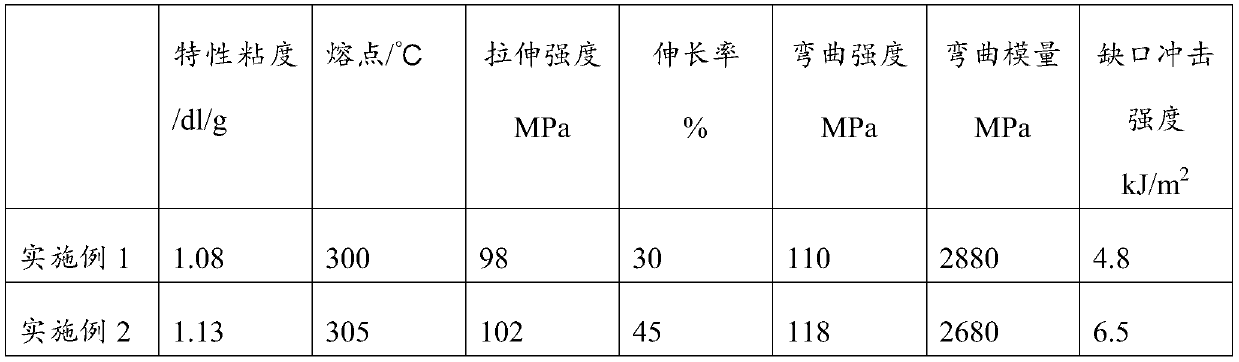

[0092] Test its intrinsic viscosit...

Embodiment 3

[0094] In this example, a semi-aromatic polyamide is actually prepared, and the steps include:

[0095](1) Put 1660g (10mol) of terephthalic acid, 1614g (10.2mol) of nonanediamine, 5Kg of ethanol and 10kg of deionized water in a 20L high pressure equipped with magnetic coupling stirring, condenser, exhaust port and pressure explosion-proof port In the kettle, heat up to 95°C and keep warm for 30min;

[0096] (2) Control the temperature at 90°C, evaporate and collect the condensed ethanol, and the collected ethanol can be reused until no obvious fraction is distilled out;

[0097] (3) Without adding 46.6g (0.5mol) of aniline, continue to heat up to 310°C, during which the water is slowly discharged, and the pressure is maintained at 3MPa, and then the pressure is reduced to 0.6MPa, and the semi-aromatic polyamide prepolymer is obtained by discharging, which is crushed After solid phase thickening at 200°C for 4h, it can be obtained.

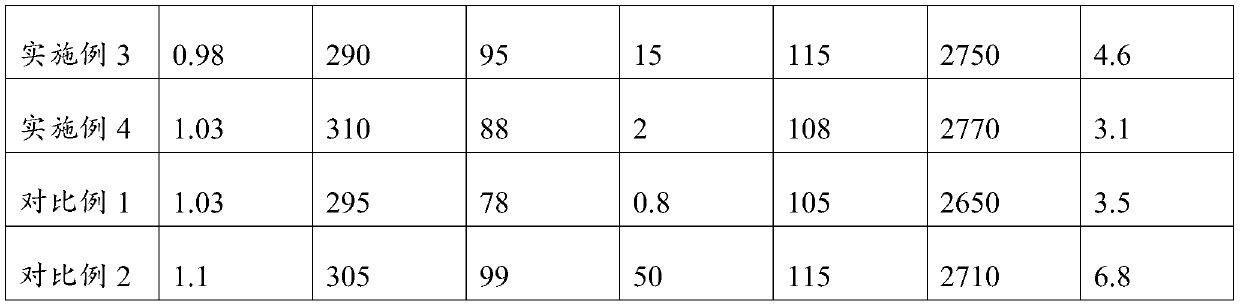

[0098] Test its intrinsic viscosity, melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com