Ventilation and dust removal device and dust removal method and purification and dehumidification method thereof

A dedusting device and wet dedusting technology, which are applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of clogging filter elements, excessive secondary waste, and high air humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

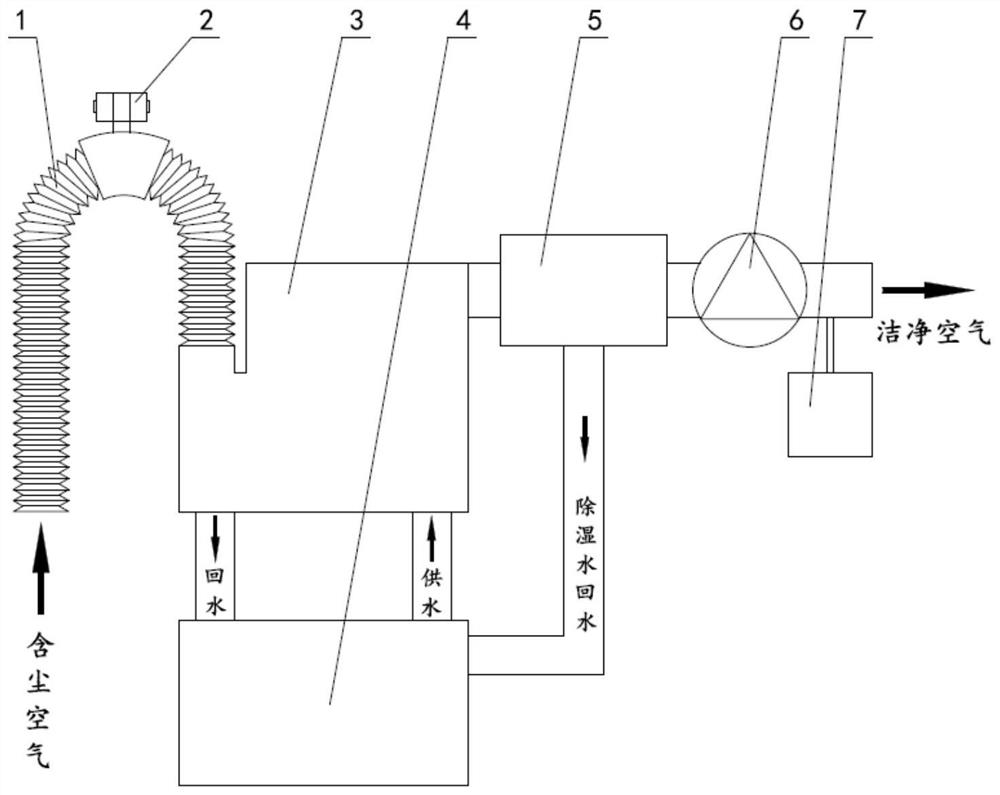

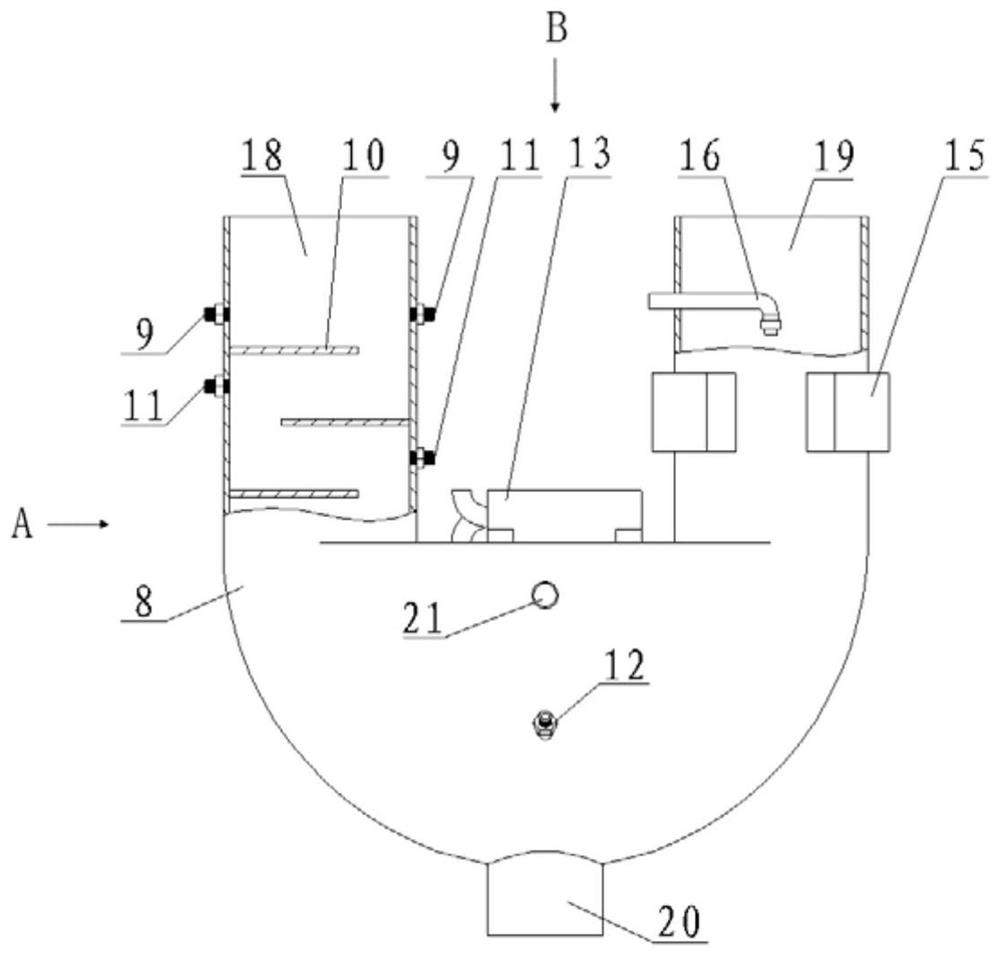

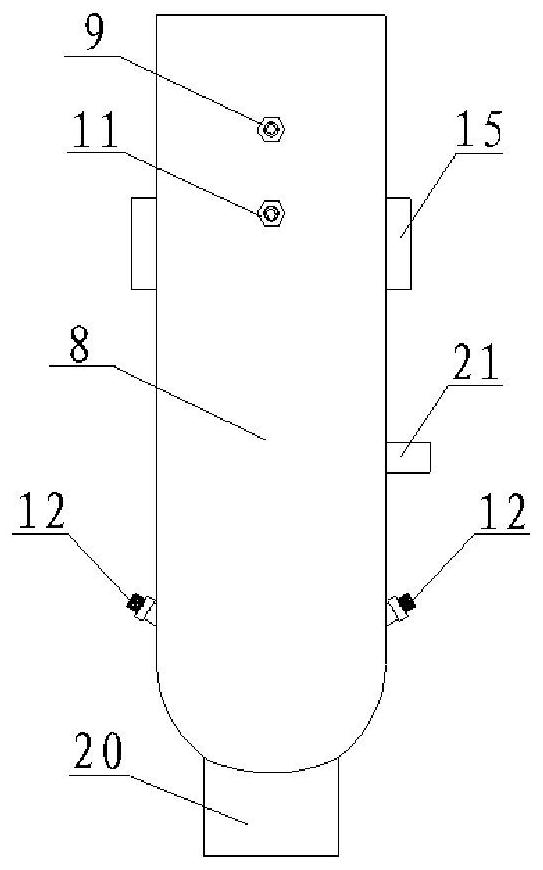

[0071] like figure 1 As shown, a kind of ventilation and dust removal device provided by the present invention is arranged on the air outlet of the mixer of the cement curing line in the cement curing plant of the nuclear power plant, including dust collection hose 1, dust falling vibrator 2, wet dust removal filter 3. The first water tank 4, the condensation dehumidification device 5, the exhaust fan 6, and the air monitoring device 7. The dusty air discharged from the mixer of the cement curing line enters the wet dust filter 3 through the dust collection hose 1 for dust removal, then enters the condensation dehumidification device 5 for dehumidification, and is treated as clean air. Discharging; the dust removal operation in the wet dust removal filter 3 is realized by using the circulating water in the first water tank 4 .

[0072] Among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com