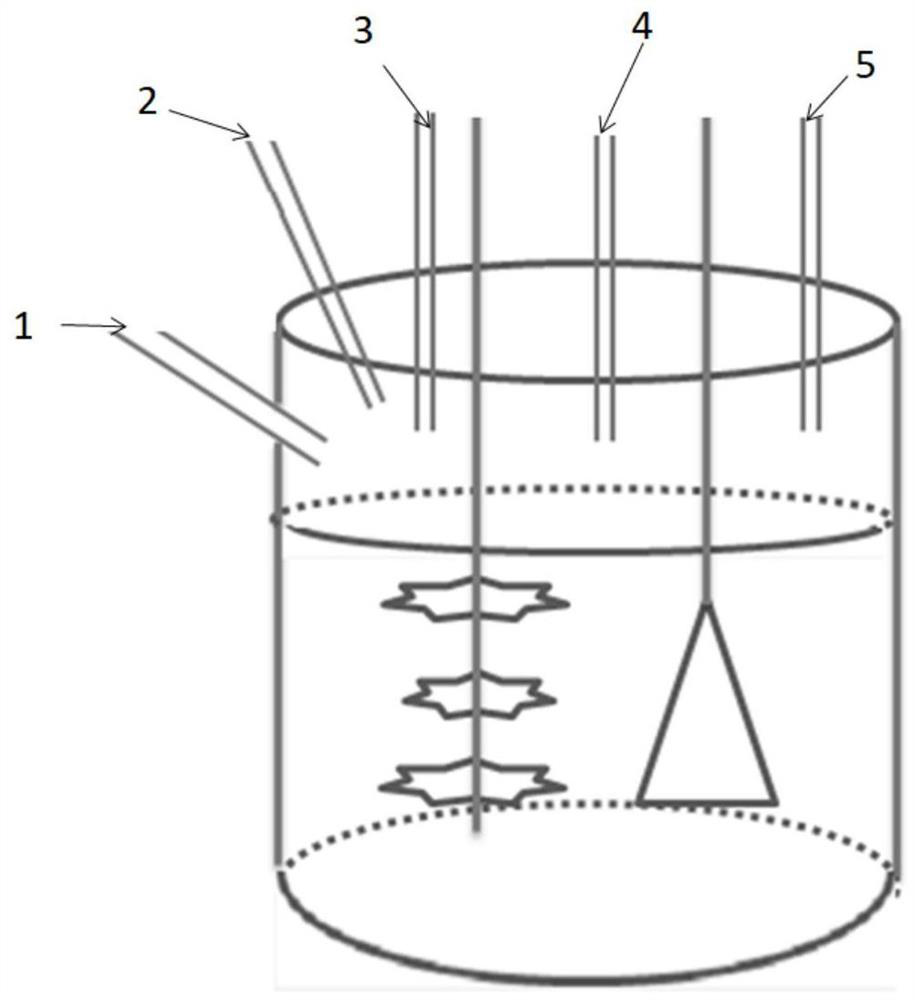

Lithium ion battery positive electrode slurry, preparation method thereof and stirring cylinder used in preparation process

A lithium-ion battery and positive electrode slurry technology, which is applied in the direction of electrode manufacturing, battery electrodes, mixing methods, etc., can solve the problems of affecting production efficiency, insufficient stirring, and increasing manufacturing costs, so as to save mixing time, improve mixing efficiency, The effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

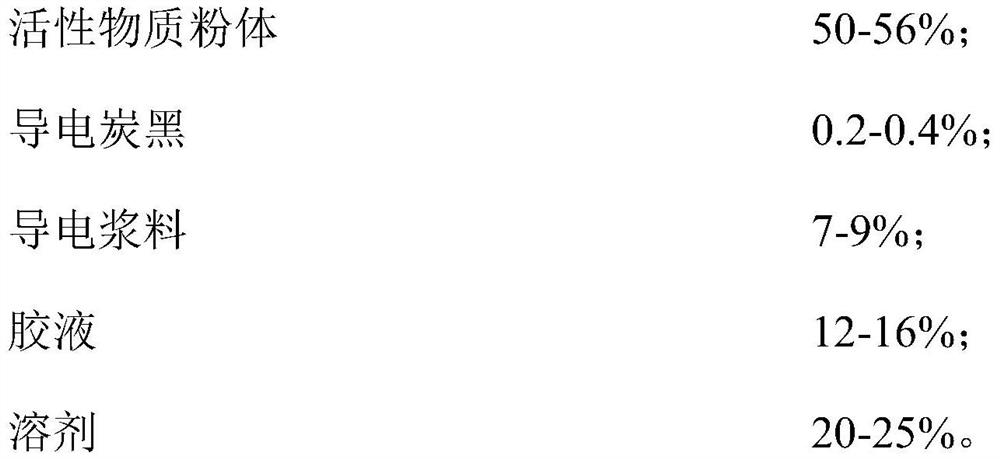

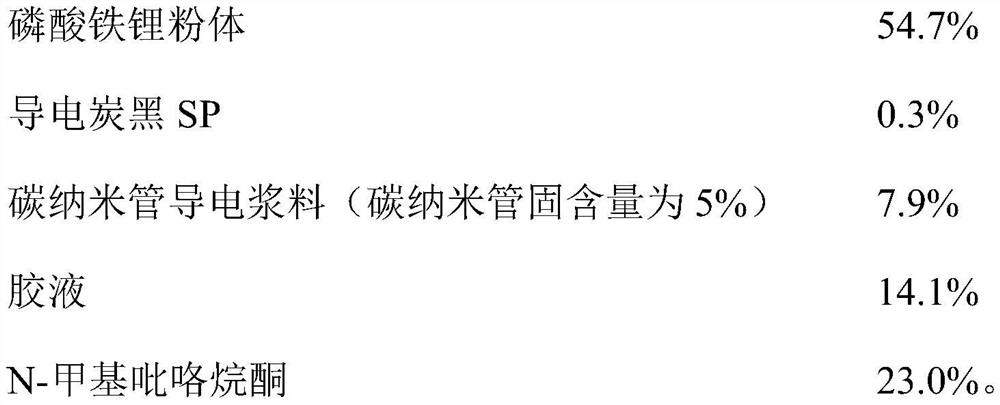

[0082] In this embodiment, the ratio of the raw materials for preparing the positive electrode slurry of the lithium ion battery; taking the mass of the positive electrode slurry of the lithium ion battery as 100%, the positive electrode slurry of the lithium ion battery contains the following components:

[0083]

[0084] The glue liquid is a mixed liquid of N-methylpyrrolidone and polyvinylidene fluoride, and its solid content is 8%.

[0085] The average particle size of the lithium iron phosphate powder is 1.1 μm, and the average particle size of the conductive carbon black SP is 10 nm.

[0086] The preparation method of the glue liquid is: adding N-methylpyrrolidone and polyvinylidene fluoride into a stirring cylinder in sequence, and mixing for 360 minutes under the conditions of a common rotation speed of 25 rpm and a stirring and dispersing speed of 2000 rpm to obtain the glue liquid.

[0087] The method for preparing the positive electrode slurry of the lithium ion battery in t...

Embodiment 2

[0094] In this embodiment, the ratio of the raw materials for preparing the positive electrode slurry of the lithium ion battery; taking the mass of the positive electrode slurry of the lithium ion battery as 100%, the positive electrode slurry of the lithium ion battery contains the following components:

[0095]

[0096] The glue liquid is a mixed liquid of N-methylpyrrolidone and polyvinylidene fluoride, and its solid content is 6%.

[0097] The average particle size of the lithium iron phosphate powder is 1.6 μm, and the average particle size of the conductive carbon black SP is 20 nm.

[0098] The preparation method of the glue is as follows: N-methylpyrrolidone and polyvinylidene fluoride are sequentially added to a stirring cylinder, and mixed for 480 minutes under the conditions of a common rotational speed of 24 rpm and a stirring and dispersing rate of 2050 rpm to obtain the glue.

[0099] The method for preparing the positive electrode slurry of the lithium ion battery in th...

Embodiment 3

[0105] In this embodiment, the ratio of the raw materials for preparing the positive electrode slurry of the lithium ion battery; taking the mass of the positive electrode slurry of the lithium ion battery as 100%, the positive electrode slurry of the lithium ion battery contains the following components:

[0106]

[0107] The glue liquid is a mixed liquid of N-methylpyrrolidone and polyvinylidene fluoride, and its solid content is 10%.

[0108] The average particle size of the lithium iron phosphate powder is 0.6 μm, and the average particle size of the conductive carbon black SP is 50 nm.

[0109] The preparation method of the glue liquid is as follows: N-methylpyrrolidone and polyvinylidene fluoride are sequentially added into a stirring cylinder, and mixed for 240 minutes under the conditions of a common rotational speed of 26 rpm and a stirring and dispersing speed of 1950 rpm to obtain the glue liquid.

[0110] The method for preparing the positive electrode slurry of the lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com