A free particle/porous medium composite enhanced boiling structure and its preparation method

A technology of enhanced boiling and porous media, applied in heat exchange equipment, lighting and heating equipment, heat transfer modification, etc., can solve the problems of enhanced boiling to maintain long-term performance, increase wall thermal resistance, etc., and achieve delayed critical heat flux The effect of volume, accelerated liquid return rate, bubble movement and small liquid return resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the particle / porous medium composite enhanced boiling structure specifically includes the following steps:

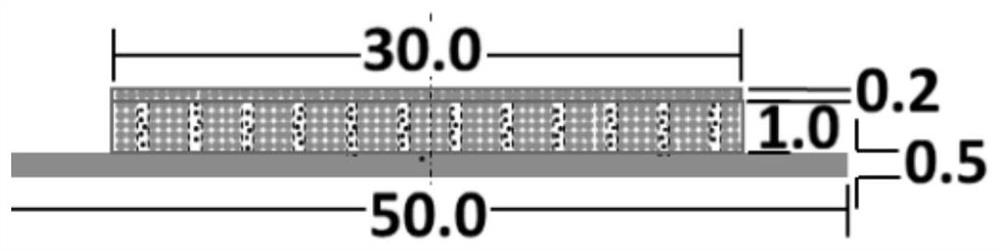

[0048] (1) Heating the substrate (50mm×50mm), and using 800 mesh, 1200 mesh, 1500 mesh, 2000 mesh, and 3000 mesh sandpaper to polish the substrate in sequence;

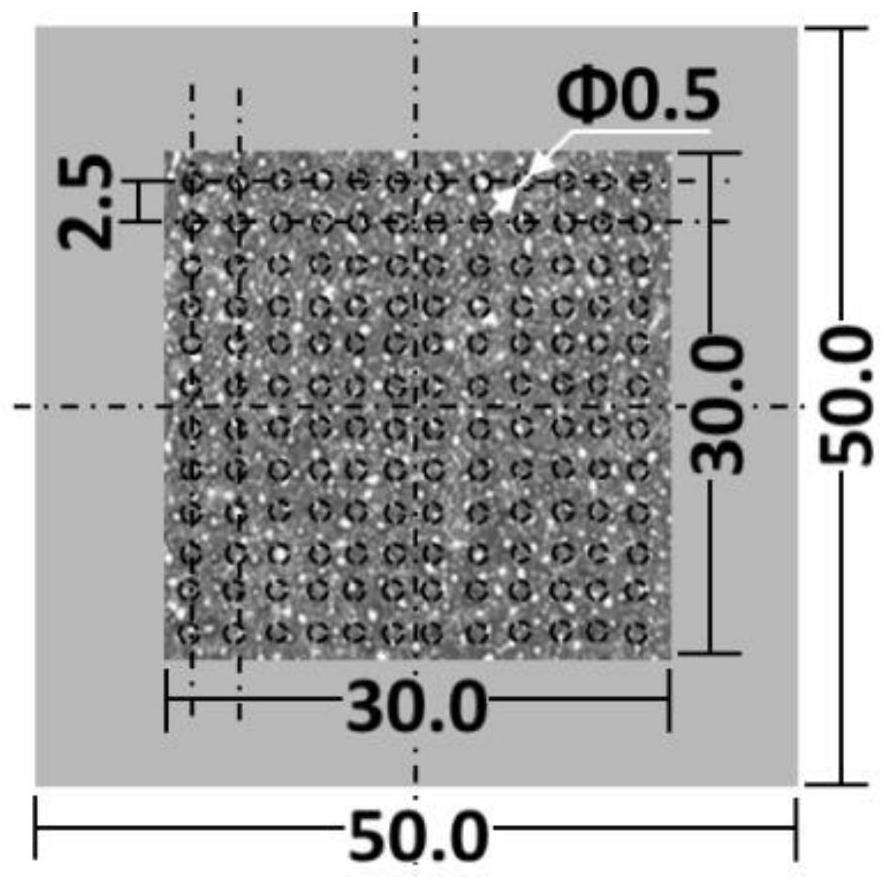

[0049] (2) Copper particle and barium chloride are mixed by volume ratio 4:1, and add the ethanol of mixing particle volume 5% to make it bond in the mixed particle, the mixture is packed in the diamond mold (30mm * 30mm), Put it on the polished surface of red copper, apply a pressure of 16MPa to compact the mixture to obtain a porous layer with a thickness of 1mm; sinter at about 870°C for 40min in a hydrogen atmosphere, cool naturally, remove the pore-forming agent by ultrasonic cleaning, and dry in vacuum to obtain Porous matrix;

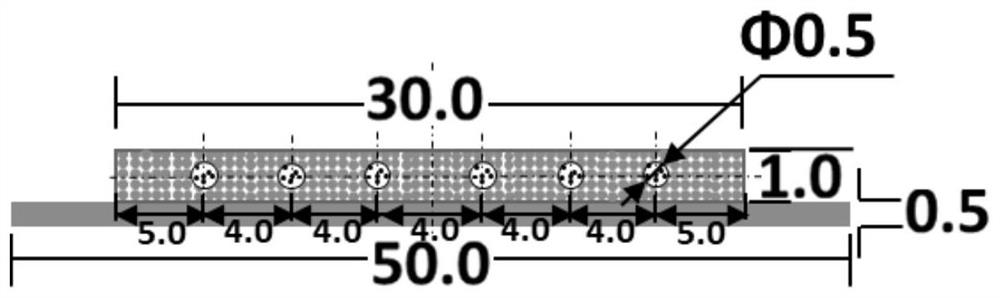

[0050] (3) Mechanically perforate the porous substrate to form a cavity with a diameter of 0.5mm, a hole spacing of 1.5mm, and a hole array of 12...

Embodiment 2

[0054] The preparation method of the particle / porous medium composite enhanced boiling structure specifically includes the following steps:

[0055] (1) Heating the substrate (50mm×50mm), and using 800 mesh, 1200 mesh, 1500 mesh, 2000 mesh, and 3000 mesh sandpaper to polish the substrate in sequence;

[0056] (2) Copper particle and barium chloride are mixed by volume ratio 4:1, and add the ethanol of mixing particle volume 5% to make it bond in the mixed particle, the mixture is packed in the diamond mold (30mm * 30mm), Put it on the polished surface of red copper, apply a pressure of 16MPa to compact the mixture, and obtain a porous layer with a thickness of 1mm; sinter at about 870°C for 40min in a hydrogen atmosphere, cool naturally for 12h, remove the pore-forming agent by ultrasonic cleaning, and dry in vacuum. Porous matrix;

[0057] (3) Holes are formed by laser perforation in the cross-section of the porous substrate, with a diameter of 0.5mm and a hole spacing of 4m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com